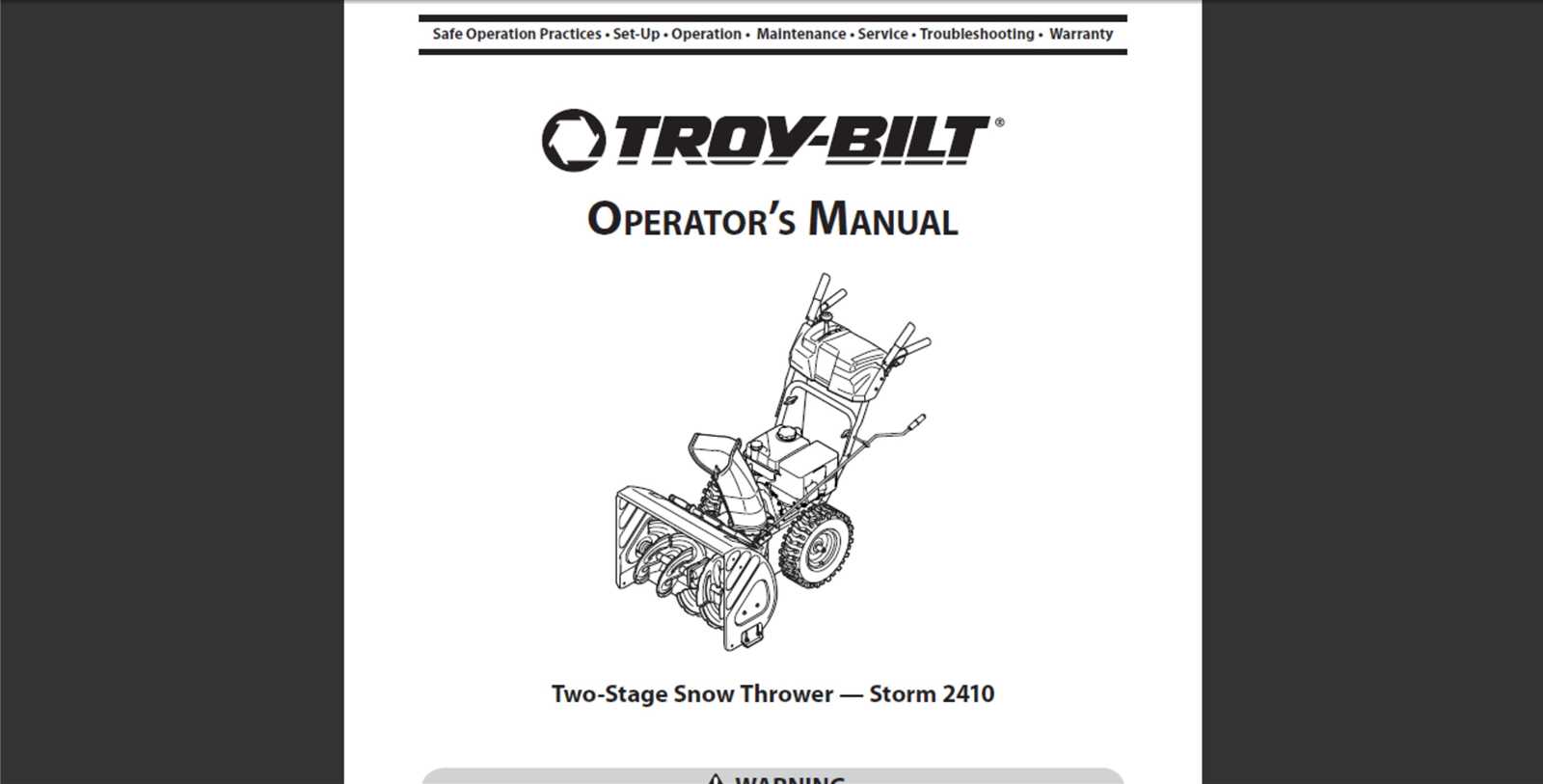

Understanding how to operate your machinery correctly is crucial for ensuring its long-lasting performance and safe operation. It is essential to become familiar with the key functions and maintenance tasks to avoid potential issues and maximize efficiency.

This resource offers detailed insights into the proper setup, usage, and care of your equipment. By following the recommendations, you can ensure your machine performs optimally while reducing the likelihood of malfunctions or costly repairs.

Additionally, regular upkeep and adherence to the guidelines provided can prolong the life of your device, offering smooth and uninterrupted service over time. In this guide, you will find practical advice on maintaining key components, troubleshooting common problems, and improving overall productivity.

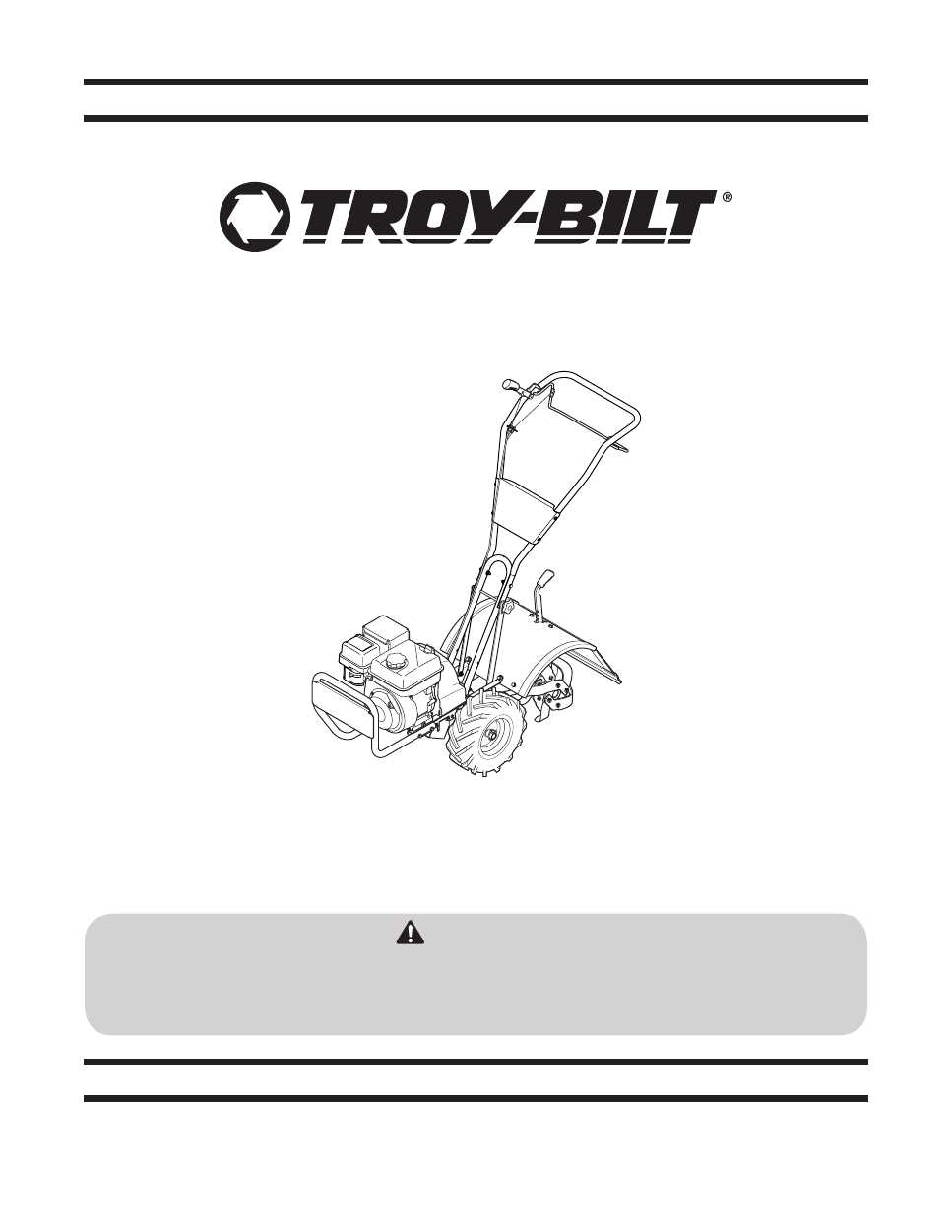

Setup Instructions for Garden Tractor

Setting up your new machine properly is essential to ensure smooth operation and durability. Before you begin, familiarize yourself with the layout and components, and ensure that all necessary tools and parts are available. Follow the steps below for a seamless installation and initial configuration.

Step 1: Unpacking and Inspection

Carefully remove the equipment from its packaging. Check for any visible damage and confirm that all components, including bolts, washers, and attachments, are accounted for. It’s important to address any missing parts before proceeding.

Step 2: Installing the Steering Wheel

Align the steering column with the provided mount. Use the appropriate hardware to securely fasten the steering wheel. Ensure that it rotates smoothly without obstruction, and make any necessary adjustments to achieve the correct angle.

Step 3: Attaching the Seat

Position the seat on the frame using the designated brackets. Secure it tightly with the included bolts, ensuring it is properly aligned and stable. Test the seat for comfort and adjust the position if needed to match your preferences.

Step 4: Connecting the Battery

Locate the battery compartment and carefully insert the battery. Attach the positive and negative cables to their corresponding terminals, ensuring a snug connection. Once connected, check that all electrical components respond correctly when powered on.

Step 5: Final Adjustments

Before starting the engine, check the tire pressure, fuel level, and all fluid levels. Adjust any

Maintenance Tips for Long-Lasting Performance

Proper upkeep of your outdoor equipment is crucial for ensuring smooth operation over the years. Consistent care and attention to detail can help avoid major breakdowns and extend the life of the machine.

- Check fluids regularly: Keep an eye on oil and other vital fluids. Regular changes and top-ups can prevent excessive wear on engine parts.

- Clean air filters: A clean filter allows for efficient airflow, improving performance and fuel efficiency. Replace or clean filters as needed.

- Inspect belts and blades: Check for wear and tear on drive belts and cutting blades. Replacing damaged parts early prevents further damage to the equipment.

- Tighten bolts and fasteners: Over time, vibrations can loosen various parts of the machine. Periodically check and tighten any loose bolts or fasteners.

- Store properly during off-seasons: Keep the equipment in a dry, sheltered area when not in use. Cover it to protect against dust, moisture, and rust.

- Before each use: Perform a quick visual inspection for leaks or loose components.

- Every 25 hours: Change the oil and check the condition of the spark plugs.

- Annually: Conduct a comprehensive inspection, including lubricating moving parts and replacing any worn components.

By following these simple steps, you can ensure that your equipment remains in peak condition, providing reliable pe

Troubleshooting Common Bronco Model Issues

Understanding and addressing frequent challenges with your equipment is essential to ensure smooth operation and prolong its lifespan. Various issues may arise during usage, and identifying the root cause can prevent further complications.

One of the most common problems is difficulty starting the engine. This can be caused by several factors, such as fuel delivery issues or a malfunctioning ignition system. Checking the fuel level, inspecting the spark plug, and ensuring that the air filter is clean are important steps in diagnosing the problem.

Another frequent issue is uneven performance during mowing. This can often be traced to the cutting blades. It’s crucial to regularly inspect and sharpen them to maintain optimal performance. Additionally, make sure the deck is level and free of debris that could obstruct smooth movement.

Finally, poor battery life or issues with electrical components can be frustrating. Ensuring that the battery is fully charged and testing electrical connections can help resolve these problems. Regular maintenance of the electrical system can prevent unexpected failures during operation.