Understanding your welding equipment is essential for achieving optimal performance and safety. This section aims to provide valuable insights into the functionalities, features, and maintenance procedures associated with a specific welding machine. With proper knowledge, users can maximize the effectiveness of their equipment while minimizing the risk of accidents or malfunctions.

In this guide, we will explore the various aspects of operating and caring for your welder. Emphasis will be placed on essential procedures that ensure longevity and reliability. From setup instructions to troubleshooting tips, this resource is designed to empower users with the information needed to operate their tools with confidence.

By following the outlined guidelines, welders can enhance their skills and achieve professional results. Whether you are a novice or an experienced user, this section will equip you with the knowledge necessary to maintain and operate your equipment effectively, ensuring that every project is completed with precision.

Understanding Your Miller Maxstar 210

The equipment in question is designed for precision and efficiency, catering to various welding needs. Its versatile capabilities enable users to handle a range of tasks, from simple repairs to complex projects. This section aims to illuminate the key features and functionalities of this powerful device, providing insights into its operation and maintenance.

Key Features

This compact unit offers remarkable portability and ease of use. With its lightweight design and robust construction, it is well-suited for both professional and personal applications. Users will appreciate the advanced control settings that allow for tailored welding experiences, ensuring optimal performance for different materials and thicknesses.

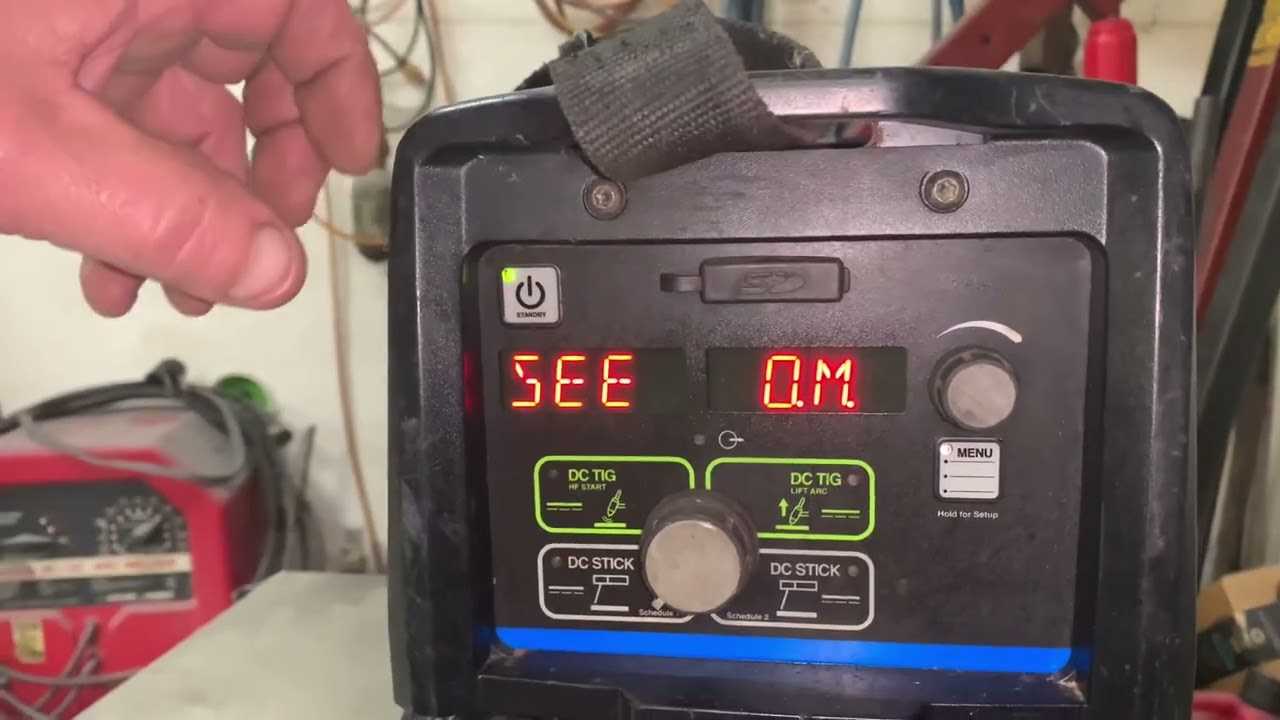

Operating Instructions

Before engaging with the device, familiarize yourself with its components and functions. Understanding the control panel is crucial, as it allows you to adjust settings to match specific welding requirements. Always refer to the safety guidelines to ensure a secure working environment, maximizing both efficiency and safety during operation.

Maintenance Tips for Longevity

To ensure the extended life and optimal performance of your welding equipment, it is essential to implement a regular maintenance routine. Proper care not only enhances functionality but also reduces the likelihood of costly repairs and downtime. Following a few simple practices can significantly increase the longevity of your device, allowing for a more efficient and productive work experience.

Regular Cleaning

Keeping the equipment clean is crucial for its proper functioning. Dust, debris, and spatter can accumulate over time, potentially causing malfunctions. Make it a habit to wipe down the exterior surfaces and check for any buildup around the ventilation areas. This will help maintain airflow and prevent overheating.

Routine Inspections

Conducting frequent inspections is vital for identifying wear and tear early. Examine cables, connectors, and hoses for any signs of damage. Additionally, ensure that all components are securely fastened and functioning correctly. Addressing minor issues promptly can prevent more significant problems in the future.

| Maintenance Task | Frequency |

|---|---|

| Clean exterior surfaces | Weekly |

| Inspect cables and connectors | Monthly |

| Check ventilation for blockages | Monthly |

| Replace worn-out parts | As needed |

| Test functionality of all settings | Before each use |

Common Troubleshooting Techniques

Effective problem-solving is essential for maintaining optimal performance in welding equipment. By understanding and applying standard diagnostic methods, users can efficiently identify and resolve issues that may arise during operation. This section will explore practical strategies for troubleshooting common challenges encountered with welding units.

Begin by systematically examining the equipment for any visible signs of malfunction. This includes checking connections, inspecting cables, and ensuring all components are secure. It’s also advisable to consult the specifications and recommended settings to confirm they align with the current operation.

| Issue | Potential Causes | Troubleshooting Steps |

|---|---|---|

| No Power | Disconnected power source, faulty cord | Verify the power supply, check the cord for damage |

| Inconsistent Arc | Incorrect settings, worn-out electrode | Adjust settings according to specifications, replace electrode |

| Overheating | Insufficient ventilation, prolonged use | Ensure proper airflow, allow equipment to cool down |

| Poor Weld Quality | Improper technique, contamination | Review welding technique, clean the workpiece thoroughly |

By following these guidelines, users can effectively diagnose issues and restore functionality, ensuring the welding equipment operates efficiently.