Maintaining and operating high-performance equipment requires a comprehensive understanding of its functionalities and best practices. This section aims to provide essential information that enhances the experience of using powerful machinery designed for outdoor tasks.

From safety precautions to maintenance schedules, each aspect plays a crucial role in ensuring optimal performance. Users will find valuable insights that help them delve into the intricacies of their devices, ultimately leading to increased efficiency and longevity.

Equipped with the right knowledge, operators can navigate potential challenges confidently. This guide serves as a vital resource for anyone looking to master their equipment and achieve the best results in their endeavors.

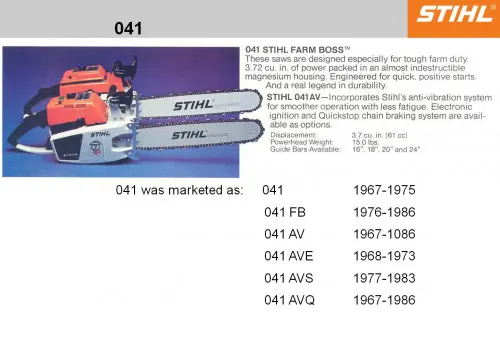

Essential Features of Stihl Farm Boss

This section explores the key characteristics that define a reliable tool for outdoor tasks. These attributes ensure efficiency, safety, and ease of use, making it a valuable asset for both professionals and hobbyists.

Powerful Engine Performance

At the heart of any effective device is a robust engine that delivers high performance. With superior power-to-weight ratio, users can expect quick cutting and reduced fatigue during extended operations.

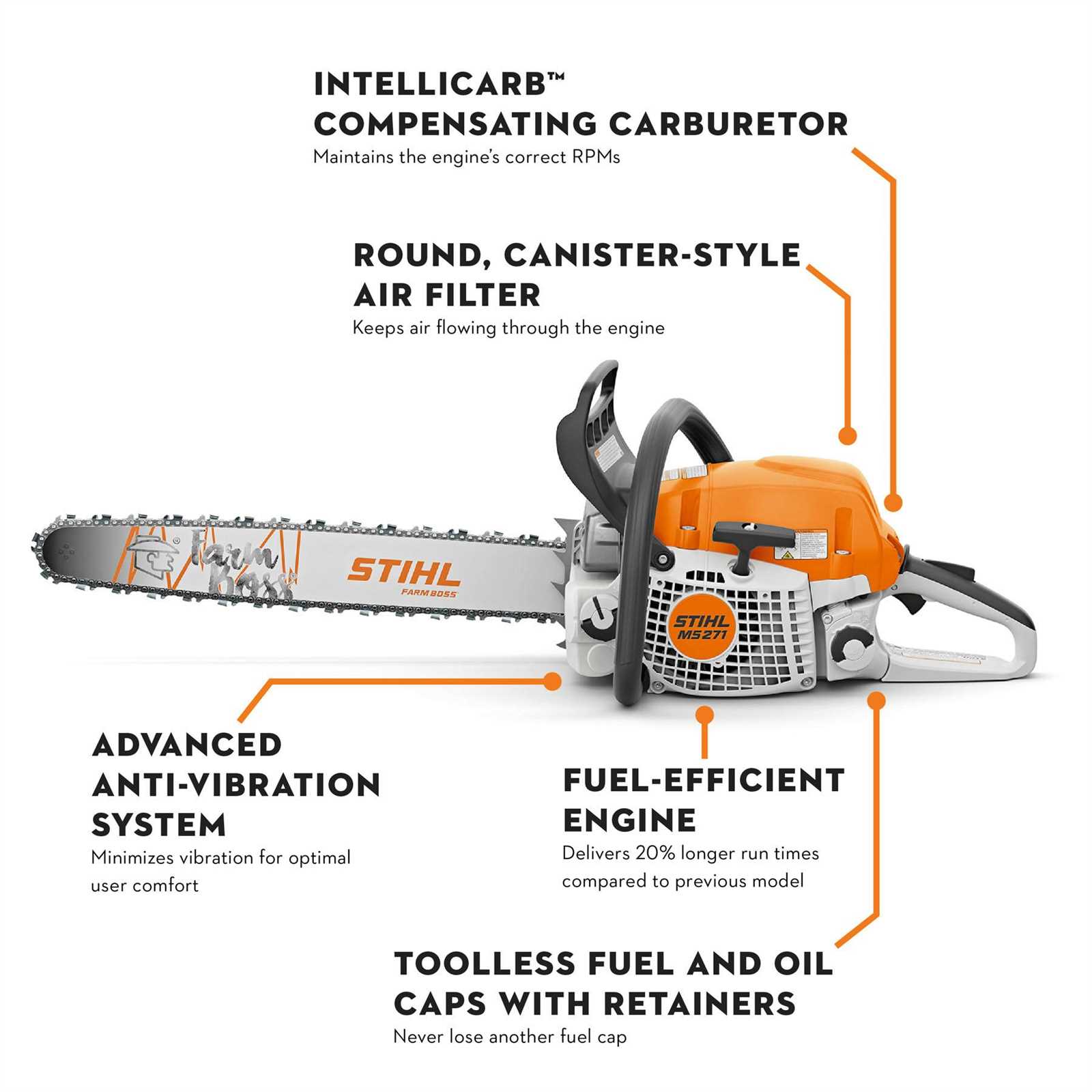

Ergonomic Design for Comfort

The user-friendly layout enhances control and minimizes strain. Features like adjustable handles and anti-vibration systems contribute to a more pleasant experience, allowing for prolonged use without discomfort.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. By following a regular maintenance schedule, you can enhance performance, prevent unexpected breakdowns, and extend the lifespan of your machinery. Here are some practical tips to keep your device in optimal condition.

Regular Cleaning

- After each use, clean the exterior to remove dirt and debris.

- Inspect and clean the air filter to ensure proper airflow.

- Keep the cutting components free of sap and other residues.

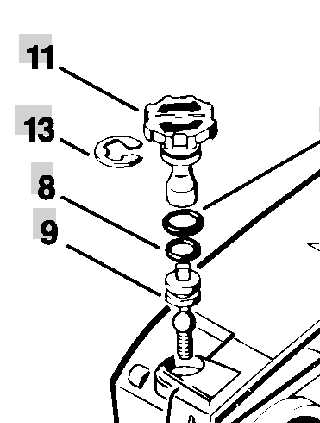

Routine Inspections

- Check all moving parts for signs of wear or damage.

- Ensure that all bolts and screws are tightened and secure.

- Examine fuel lines and connectors for leaks or cracks.

Implementing these maintenance practices will contribute to the longevity of your equipment and ensure it operates at its best for years to come.

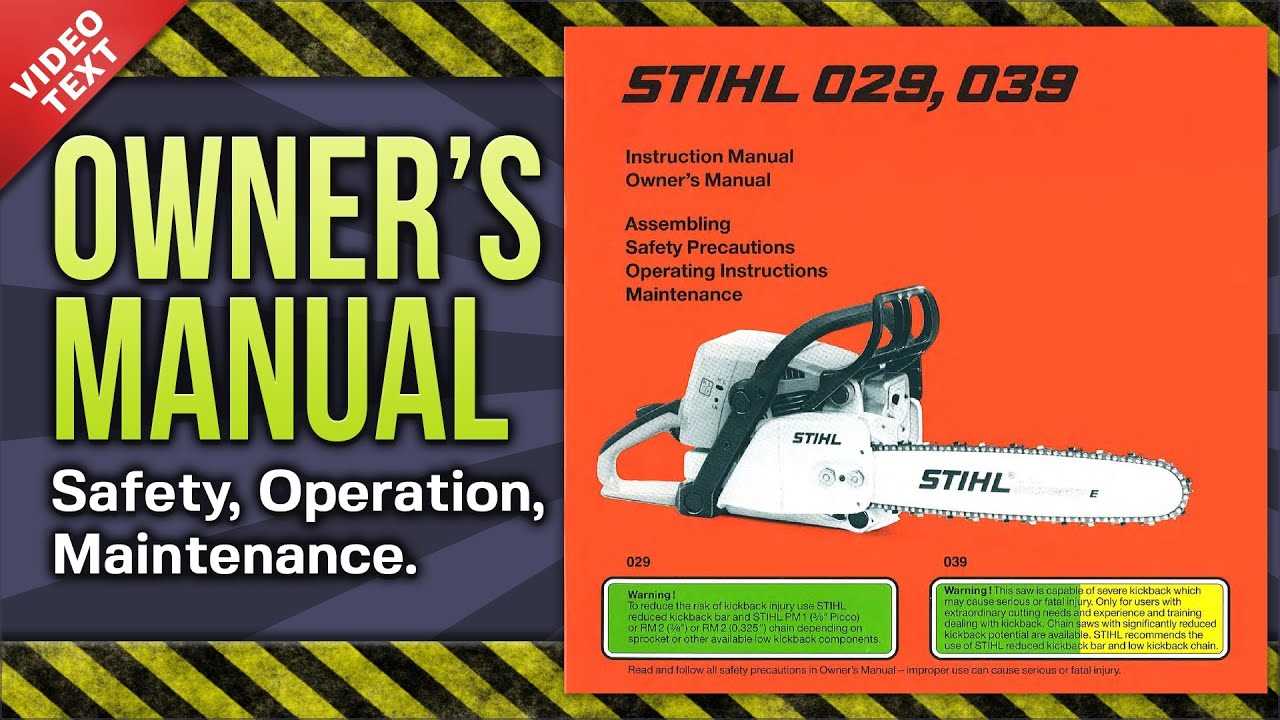

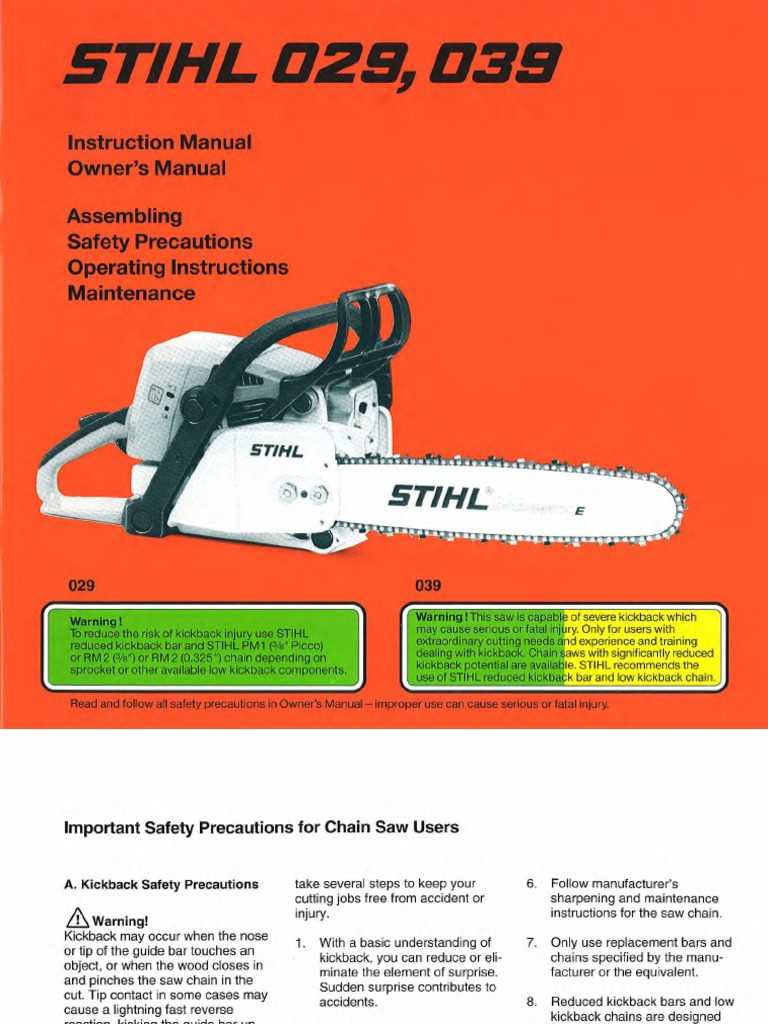

Understanding Safety Guidelines and Precautions

Ensuring safety while operating machinery is paramount for both efficiency and protection. Familiarizing yourself with essential safety measures can significantly reduce the risk of accidents and injuries. Proper awareness of hazards and adherence to recommended practices fosters a secure working environment, enabling you to focus on tasks at hand.

Essential Safety Equipment

Wearing appropriate personal protective equipment (PPE) is critical. This includes gloves, goggles, and ear protection to safeguard against potential dangers. Each item serves a unique purpose in shielding you from flying debris, excessive noise, and other environmental risks. Always ensure that your gear is in good condition and fits properly.

Operational Guidelines

Before using any machinery, it is vital to conduct a thorough inspection. Look for any signs of wear or damage that may affect performance. Additionally, understanding the operational controls and features is crucial for safe handling. Always maintain a clear work area and avoid distractions, as this can lead to dangerous situations. Remember, safety should always be your top priority.