Understanding the intricacies of your machinery is essential for optimal performance and longevity. This section provides vital insights and practical information that will aid in mastering the equipment’s functionalities and features.

From essential maintenance tips to operational guidelines, the content aims to equip users with the necessary knowledge to handle their tasks efficiently. Emphasizing safety and proper handling, this resource is designed to ensure users can confidently navigate the various aspects of their equipment.

Whether you are a seasoned professional or a newcomer, having access to comprehensive information will enhance your experience and effectiveness. With this guide, you’ll be better prepared to tackle challenges and make informed decisions about your machinery.

Understanding Your Kubota LA211 Features

The equipment in question boasts a range of capabilities designed to enhance efficiency and performance during various tasks. These functionalities cater to both novice and experienced users, ensuring that each operation is executed with precision.

One notable aspect is its versatility, allowing for seamless transitions between different attachments and implements. This adaptability enables users to tackle a variety of jobs, from landscaping to agricultural applications, with ease.

Additionally, the ergonomic design of the controls ensures comfort during prolonged use, minimizing fatigue and promoting productivity. Understanding these features will empower users to make the most of their equipment, ensuring optimal performance in every application.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring long-lasting efficiency and reliability of your equipment. By following a few key practices, you can enhance performance and extend the lifespan of your machinery.

- Check fluid levels regularly, including engine oil and hydraulic fluid.

- Inspect and clean air filters to maintain optimal airflow.

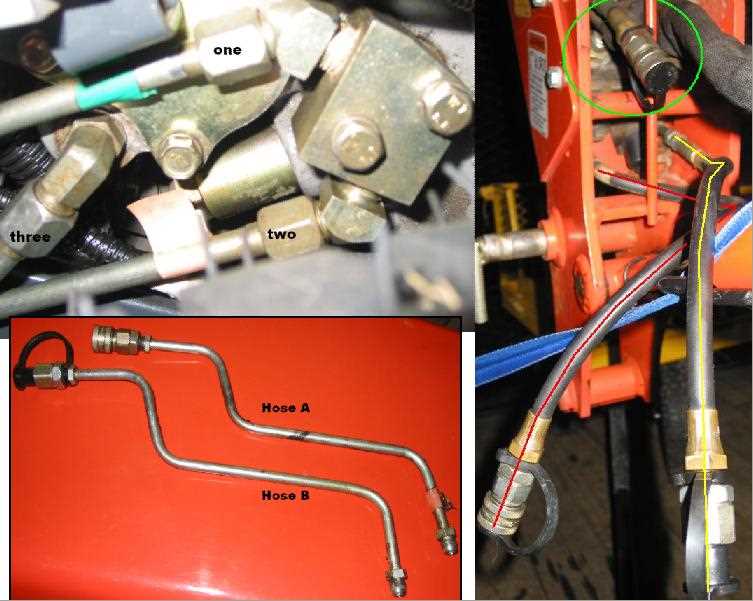

- Ensure all belts and hoses are in good condition and free from cracks or wear.

- Lubricate moving parts to reduce friction and prevent wear.

- Examine tires for proper inflation and tread wear.

Implementing a consistent maintenance schedule will help you identify potential issues early and keep your equipment running smoothly. Remember, preventive measures can save time and costs associated with major repairs.

Troubleshooting Common Issues

This section aims to assist users in identifying and resolving frequent problems encountered with their machinery. Understanding common malfunctions can lead to timely fixes, ensuring optimal performance and longevity.

Identifying Symptoms

Recognizing the signs of potential issues is the first step in troubleshooting. Below are typical symptoms and their possible causes:

| Symptom | Possible Cause |

|---|---|

| Engine Won’t Start | Defective battery or fuel supply issues |

| Overheating | Coolant level low or blocked radiator |

| Strange Noises | Worn belts or loose components |

Basic Solutions

Implementing simple troubleshooting steps can resolve many issues:

1. Check fluid levels regularly and top off as needed.

2. Inspect belts and hoses for wear and replace if necessary.

3. Ensure all connections are secure to prevent malfunctions.