For those who are engaged in the agricultural or construction sectors, understanding the intricacies of your machinery is essential for efficient operation and maintenance. This resource aims to equip users with vital insights and operational guidelines that enhance productivity and ensure the longevity of the equipment. Knowledge is power, especially when it comes to handling complex machinery.

The following sections will delve into essential topics such as safety protocols, maintenance tips, troubleshooting methods, and operational best practices. By familiarizing yourself with these elements, you will be better prepared to navigate any challenges that may arise while using your machine. Furthermore, this guide emphasizes the importance of regular upkeep, ensuring that your equipment remains in peak condition throughout its lifespan.

Ultimately, empowering yourself with comprehensive knowledge of your machine can lead to improved efficiency, reduced downtime, and a safer working environment. Embrace the opportunity to enhance your expertise and make the most of your investment in heavy machinery.

Understanding the John Deere 323D Features

This section delves into the various characteristics and functionalities that enhance the performance of this compact equipment. Designed for versatility and efficiency, it is crucial for users to familiarize themselves with the unique offerings that contribute to its effectiveness on the job site.

The machine boasts a range of features tailored to improve operational capability and user experience. Below is a summary of key attributes:

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust engine, it delivers high horsepower for demanding tasks. |

| Compact Design | Its compact size allows for easy maneuverability in tight spaces. |

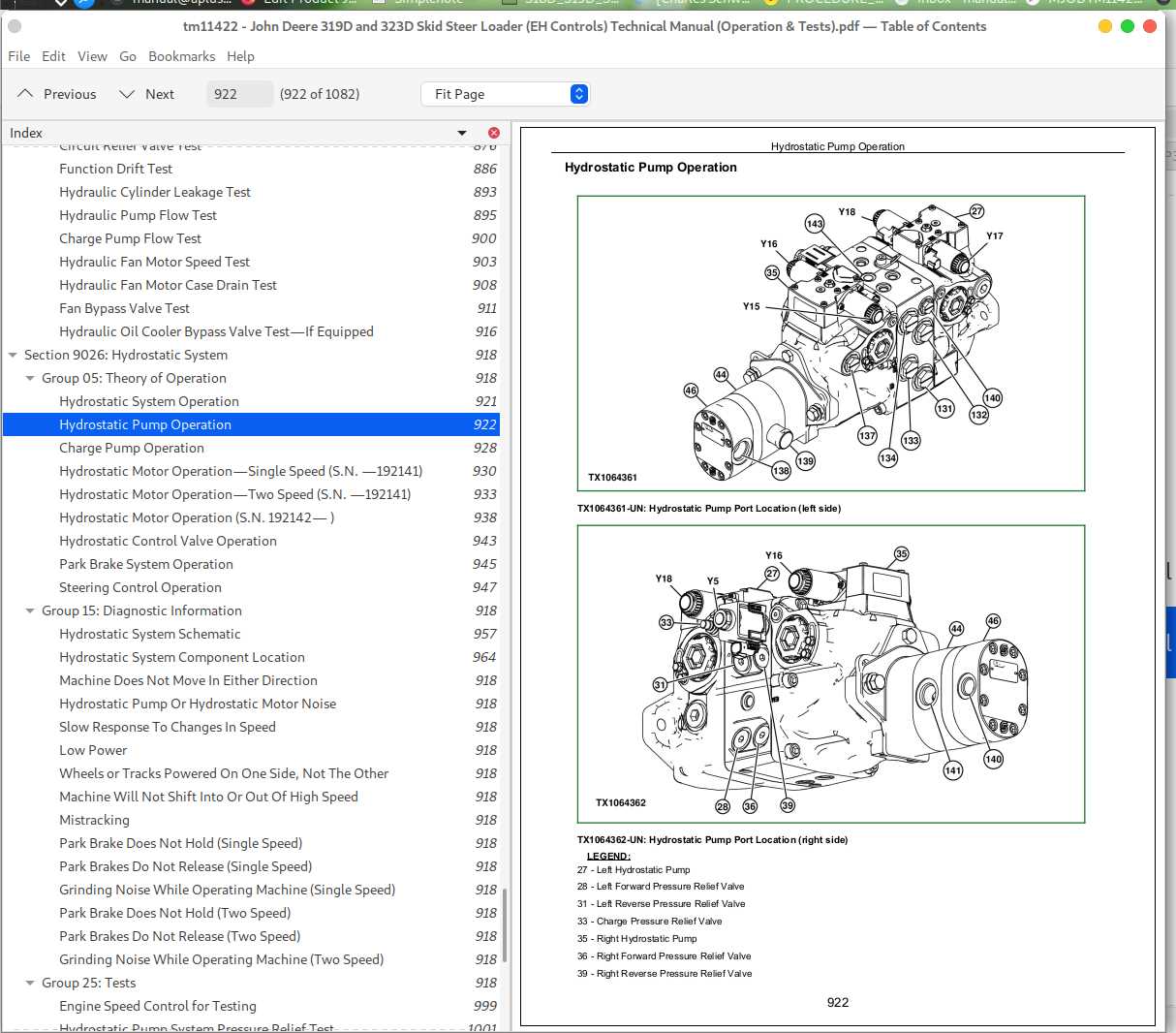

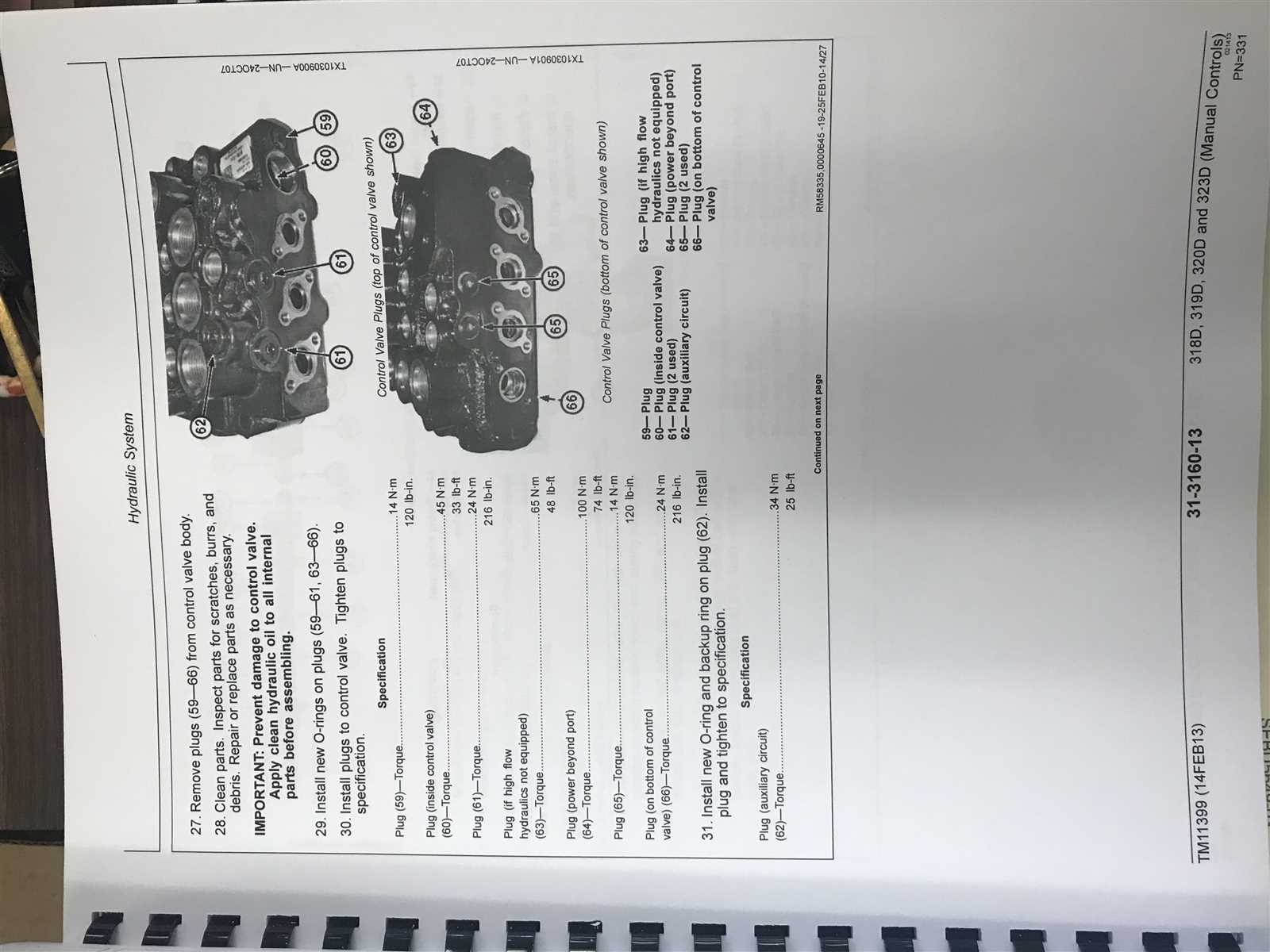

| Hydraulic System | Advanced hydraulic capabilities ensure optimal performance in various applications. |

| User-Friendly Controls | Intuitive controls make operation simple, reducing the learning curve for new users. |

| Durable Build | Constructed from high-quality materials, it withstands rigorous use over time. |

By understanding these features, users can maximize the potential of this machine, ensuring efficient and effective operation in a variety of settings.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the efficient operation and longevity of your machinery. By following a structured maintenance schedule, you can enhance productivity and minimize unexpected breakdowns. Here are some essential guidelines to maintain peak performance.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Fluid Levels | Weekly | Inspect and top off hydraulic fluid, engine oil, and coolant to ensure proper functioning. |

| Clean Air Filters | Monthly | Remove and clean air filters to prevent dust and debris from obstructing airflow. |

| Inspect Belts and Hoses | Monthly | Check for wear and tear, and replace any frayed or damaged belts and hoses to prevent failures. |

| Lubricate Moving Parts | Every 50 Hours | Apply lubricant to pivot points and joints to reduce friction and wear. |

| Examine Tires | Monthly | Check tire pressure and tread for wear to ensure safety and efficiency. |

Implementing these maintenance practices will significantly contribute to the reliable operation of your equipment. Consistency is key to avoiding costly repairs and extending the life of your machinery.

Common Issues and Troubleshooting Guide

This section provides an overview of frequent challenges that users may encounter with their equipment, along with practical solutions. By understanding these common problems and their remedies, operators can ensure smoother performance and minimize downtime.

Frequent Problems

Operators often face several typical issues that can affect functionality. Awareness of these problems helps in quick identification and resolution, enhancing overall efficiency.

| Issue | Symptoms | Suggested Solutions |

|---|---|---|

| Starting Difficulties | Engine does not start or cranks slowly. | Check the battery charge, inspect starter connections, and examine the fuel system for blockages. |

| Overheating | Temperature gauge reads high, steam from engine. | Inspect coolant levels, ensure radiator is clean, and verify that the thermostat is functioning properly. |

| Hydraulic Issues | Slow or unresponsive hydraulic functions. | Check hydraulic fluid levels, inspect hoses for leaks, and replace filters as necessary. |

| Unusual Noises | Grinding or clunking sounds during operation. | Examine belts and pulleys for wear, and check for loose components in the engine bay. |

Preventative Measures

Regular maintenance is key to preventing many issues. Adhering to service schedules and conducting routine inspections can significantly enhance reliability and extend the lifespan of the equipment.