Understanding how to properly care for and operate your equipment is crucial for achieving the best performance and longevity. This guide offers essential insights into maintaining a zero-turn mower, ensuring both durability and safety during use. From routine upkeep to troubleshooting common issues, it’s designed to help users get the most out of their machine.

With detailed instructions, you will learn how to handle various aspects of the machine’s upkeep, from engine checks to blade maintenance. Whether you’re new to maintaining lawn equipment or a seasoned user, this resource aims to simplify the process with easy-to-follow steps and helpful advice for optimizing performance.

Regular attention to various components not only improves functionality but also enhances the overall user experience. By following the tips and techniques provided, you can enjoy smoother operation and extend the lifespan of your machine, allowing it to perform at its best for years to come.

Understanding the Key Features of the John Deere Z425

This section provides an in-depth look at the essential aspects of a well-known riding mower model. Designed for efficiency and ease of use, it stands out in the landscape of home lawn care. Below, we will explore the specific attributes that make it a popular choice among homeowners seeking both performance and reliability.

Efficient Cutting System

The machine is equipped with a highly efficient cutting mechanism, allowing for clean and precise grass trimming. The design ensures an even cut across various terrain types, ensuring that your lawn maintains a polished look with minimal effort.

User-Friendly Operation

Built with the operator’s convenience in mind, this model features intuitive controls and a comfortable seating arrangement. The system is designed to make long mowing sessions less strenuous, offering a smoother and more enjoyable experience for those handling larger properties.

Safety Precautions and Maintenance Guidelines

Ensuring the longevity and safe operation of your equipment requires adhering to essential safety measures and consistent upkeep. Proper handling, combined with regular inspections, is key to avoiding accidents and keeping the machine in optimal condition.

General Safety Instructions

Before operating any machinery, always familiarize yourself with its controls and functions. It is critical to inspect the surrounding environment for potential hazards, such as obstacles or uneven terrain, that may affect stability. Always wear appropriate safety gear, including eye and ear protection, and never bypass any safety mechanisms that are built into the equipment.

Routine Maintenance Tips

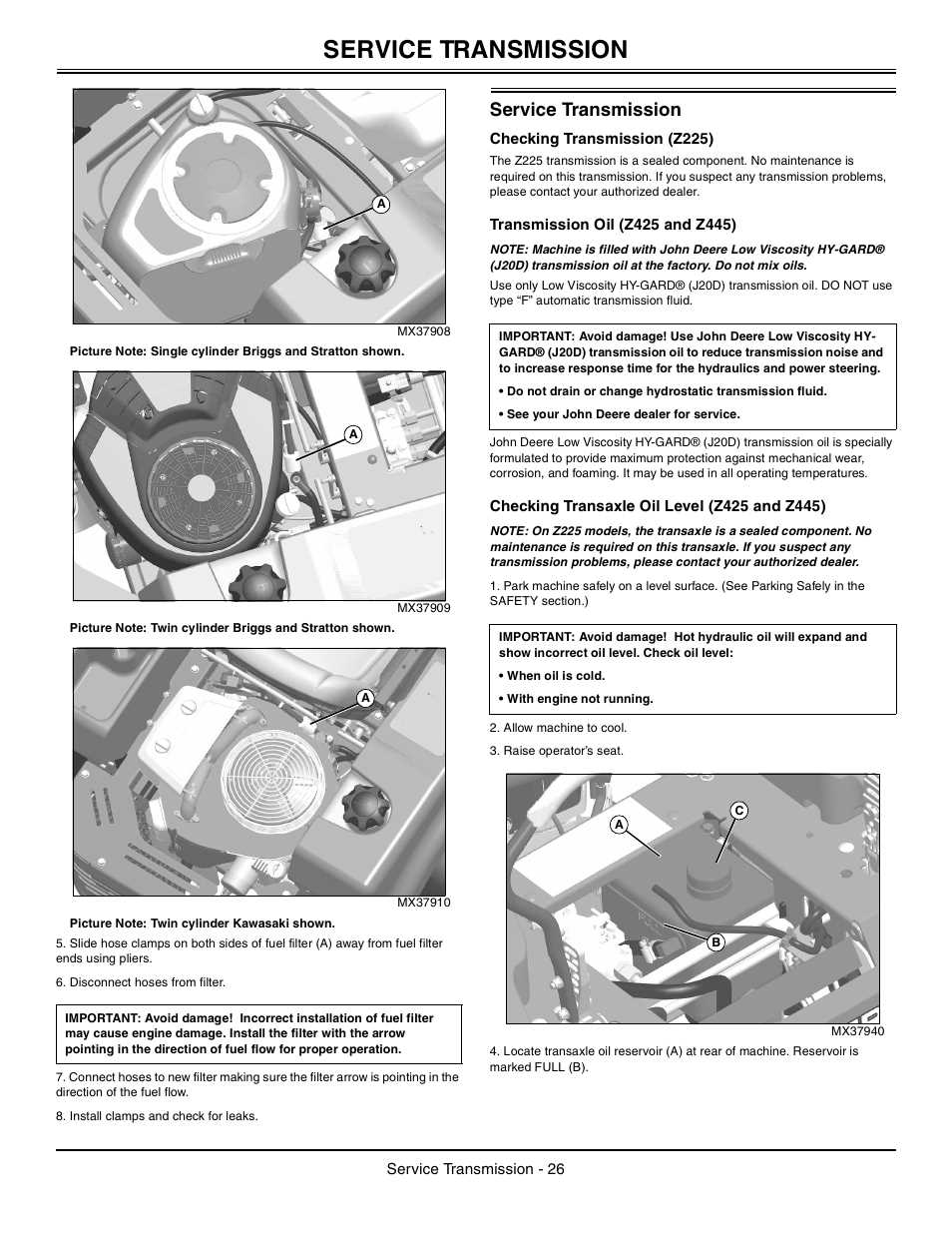

To ensure smooth functionality, perform regular checks on moving parts, lubrication points, and fasteners. Clean the equipment after each use to prevent buildup of debris that can cause blockages or wear. Periodically check the fluid levels, belts, and blades, replacing any worn components as necessary to prevent breakdowns during operation.

Operating Procedures for Maximum Efficiency

To achieve peak performance and ensure longevity of your equipment, it is essential to follow proper operational techniques. By adopting efficient procedures, you can maintain smooth operation and reduce unnecessary wear, optimizing both the machine’s productivity and your overall experience.

One key to maximizing efficiency is maintaining optimal speed and control based on the terrain. Avoid operating at high speeds in uneven areas, as this can lead to uneven results and potentially harm the machine. Adopting a moderate pace will allow for more precise handling and better fuel efficiency.

Additionally, regularly checking the condition of the blades and ensuring proper tire inflation can prevent performance issues. Sharp blades contribute to cleaner cuts, while well-inflated tires improve maneuverability and reduce energy consumption.

| Procedure | Benefit |

|---|---|

| Moderate speed control | Enhanced precision and reduced fuel use |

| Regular blade sharpening | Cleaner cuts and prolonged blade life |

| Proper tire maintenance | Better control and lower energy consumption |

Troubleshooting Common Issues with the Z425

Regular maintenance and timely identification of problems can significantly extend the life of your equipment. In this section, we will explore frequent operational challenges and how to address them efficiently. Understanding the root cause of malfunctions allows for swift repairs, reducing downtime and ensuring smooth performance.

Engine Won’t Start

If the engine fails to start, the issue may stem from a variety of factors. First, check the fuel level and ensure the tank is filled. Inspect the battery connections to confirm they are secure and free of corrosion. If the battery is charged and the fuel system is in order, check the ignition system and replace any faulty parts if necessary.

Uneven Cutting

One common concern is uneven grass cutting. This can often be attributed to dull blades or an imbalanced cutting deck. Make sure to sharpen the blades regularly and verify that the deck is level. Adjusting the tire pressure may also help achieve a more uniform cut, as uneven tires can cause imbalance.

Identifying and Resolving Mechanical Problems

Proper maintenance and timely attention to mechanical issues are crucial for ensuring the smooth operation of your equipment. Addressing problems early can prevent more severe damage and extend the life of your machine. In this section, we will explore common issues that may arise and offer steps to effectively troubleshoot and repair them.

Common Issues

Mechanical systems are prone to wear and tear over time. Some of the most frequent issues include unusual noises, reduced performance, or visible signs of wear on critical parts. Identifying these signs early allows for quick and effective repairs.

Step-by-Step Troubleshooting

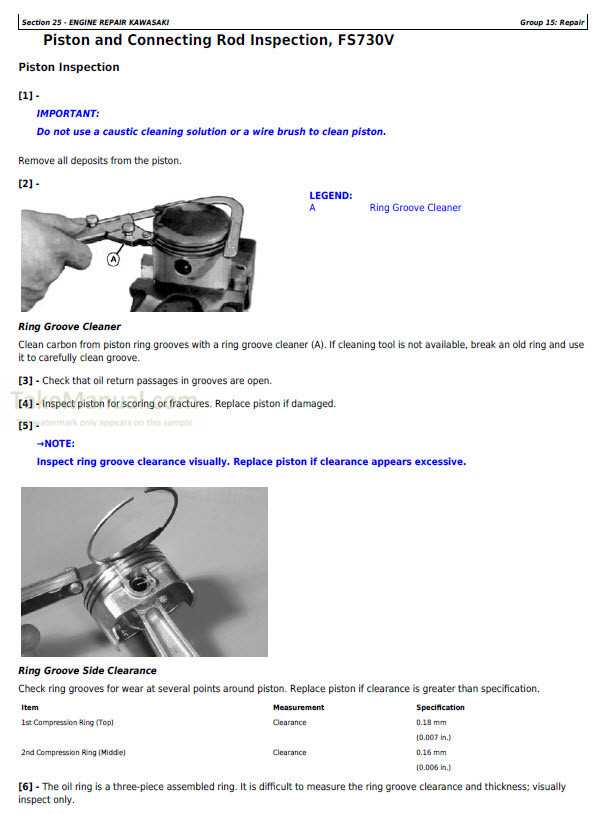

When diagnosing a mechanical problem, it’s essential to follow a systematic approach. Begin by inspecting visible components for obvious damage, such as cracks, loose parts, or leaks. If no external issues are found, proceed to check the internal mechanisms and key moving parts. Always ensure that all systems are properly lubricated and functioning within normal parameters.

Preventive Measures

To avoid frequent breakdowns, regular maintenance is key. Ensure that all parts are properly tightened, lubricated, and free from debris. Periodic checks of vital components can significantly reduce the risk of malfunction.

By staying vigilant and addressing mechanical issues promptly, you can minimize downtime and maintain optimal performance. With the right approach, identifying and resolving problems becomes a straightforward process.