This section aims to provide essential insights and guidance for users of small agricultural machinery. Understanding the intricacies of these powerful tools is crucial for efficient operation and maintenance.

Farmers and landowners alike can benefit from a thorough comprehension of their equipment’s features and capabilities. This guide serves as a valuable resource, helping to enhance productivity and ensure the longevity of the machinery.

By exploring various operational techniques and maintenance tips, users can optimize their experience and safeguard their investment. Emphasizing safety and best practices is fundamental to achieving excellent results while using these versatile machines.

Kubota BX23 Overview and Features

This compact machine is designed for versatility and efficiency in various agricultural and landscaping tasks. It combines robust construction with advanced technology to deliver exceptional performance in tight spaces.

Key Specifications

Featuring a powerful engine, this model provides reliable output while maintaining fuel efficiency. Its compact dimensions allow for easy maneuverability, making it ideal for residential and commercial projects.

Unique Functions

Equipped with innovative attachments, this unit can perform a wide range of functions, from digging to lifting. The intuitive controls ensure ease of use, even for beginners, while enhancing productivity in the field.

Maintenance Tips for BX23 Owners

Proper upkeep is essential for ensuring the longevity and efficiency of your equipment. Regular maintenance not only enhances performance but also prevents unexpected breakdowns.

- Check fluid levels regularly, including engine oil, coolant, and hydraulic fluid.

- Inspect air filters and clean or replace them as needed to ensure optimal airflow.

- Examine belts and hoses for signs of wear or damage, replacing them promptly.

- Sharpen or replace cutting blades to maintain effective performance.

- Grease all moving parts periodically to reduce friction and wear.

- Clean the exterior and undercarriage to prevent rust and debris buildup.

By adhering to these guidelines, you can enhance the operational lifespan of your equipment while ensuring it remains in top-notch condition.

Common Issues and Solutions

In the realm of compact machinery, various challenges may arise that require attention. Understanding these common difficulties can aid operators in effectively troubleshooting and maintaining optimal performance. Below are typical issues encountered by users and their respective remedies.

Engine Performance Problems

Symptoms: Reduced power output, unusual noises, or difficulty starting the engine.

Solutions: First, check the fuel levels and ensure the fuel filter is clean. Inspect the air filter for blockages and replace if necessary. If the problem persists, consider consulting a technician to evaluate the ignition system.

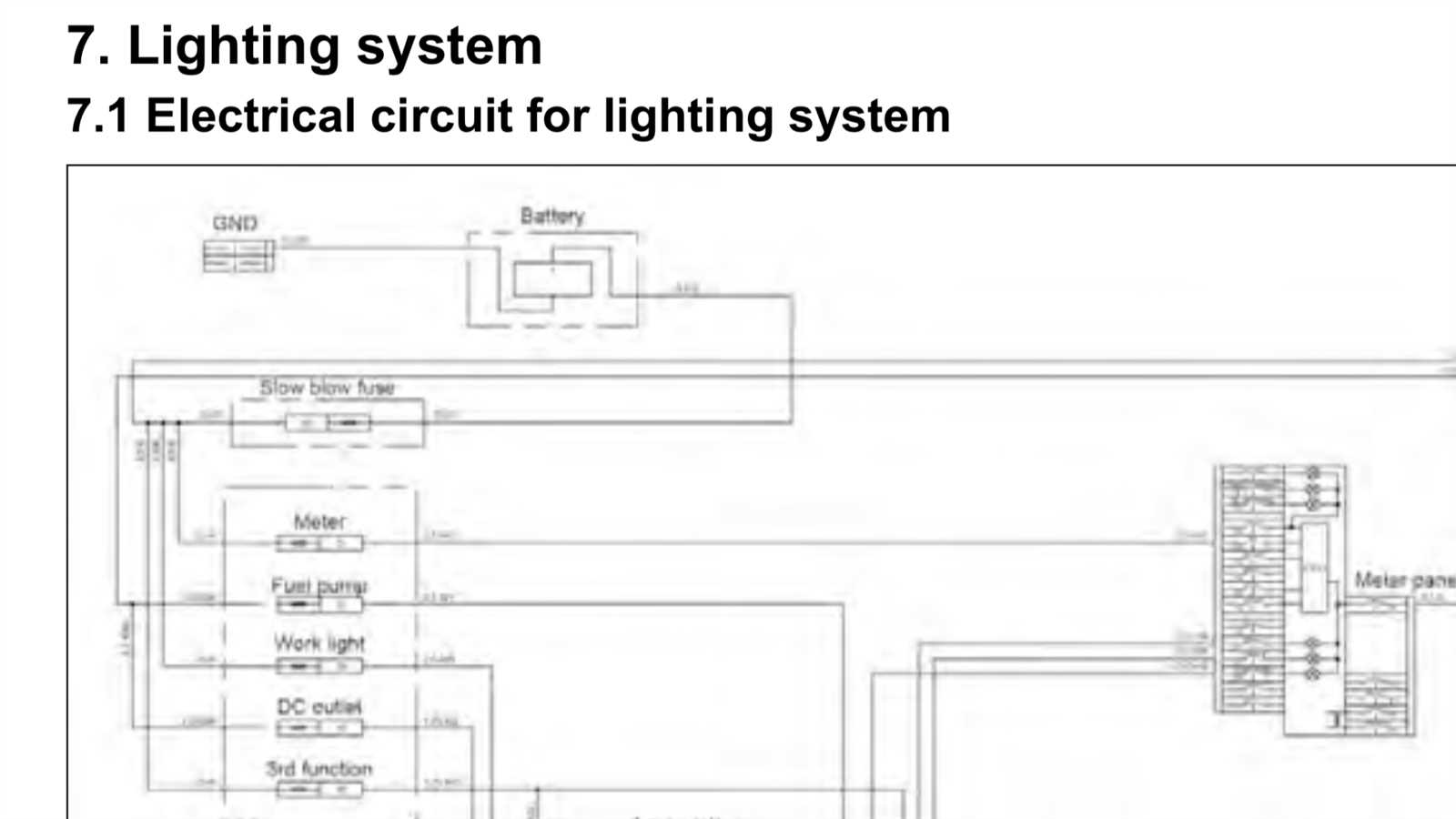

Hydraulic System Malfunctions

Symptoms: Inconsistent operation of attachments or sluggish response when using hydraulic controls.

Solutions: Begin by examining the hydraulic fluid levels and look for any leaks in hoses or connections. Ensure that the hydraulic filter is not clogged. Regular maintenance of the hydraulic system can prevent many issues from developing.