Understanding how to efficiently operate and maintain your lawn equipment is essential for keeping your property in top shape. With the right approach, you can optimize performance, extend the lifespan of your machine, and ensure that all its features are utilized to their full potential.

This section provides a clear overview of the features and functionalities of a versatile garden tractor model. By familiarizing yourself with its various components, you’ll be able to perform routine maintenance and troubleshooting with confidence. The guide also covers safety procedures to keep in mind while operating your machine.

Whether you’re a new user or an experienced operator, this guide will help you make the most of your lawn care equipment, ensuring efficient and reliable performance in a wide range of tasks.

Understanding Basic Operations

Mastering fundamental tasks with this equipment ensures optimal performance and efficiency. Knowing how to handle its various features will allow smooth operation in diverse conditions. It is essential to familiarize yourself with the core functionalities and essential controls, as this knowledge guarantees effective and safe use.

Starting and Stopping the Machine

Activating and deactivating the equipment requires attention to a few key procedures. Before starting, ensure all safety checks are completed, and the necessary levers are positioned correctly. Stopping the machine follows a similar sequence, involving secure shutdown processes to avoid unnecessary wear.

Basic Movement and Steering

Efficient control of movement is achieved through an intuitive steering mechanism. Familiarizing yourself with the steering and directional controls will help in navigating different terrains. Understanding the throttle and speed adjustments is also crucial for seamless operation, adapting the machine to varying workloads.

Maintenance Tips for Prolonging Lifespan

Regular care and attention to your equipment can significantly extend its service life. Following simple steps to maintain mechanical components and checking the essential systems will ensure that it continues to operate efficiently and reliably for years to come. Small, consistent efforts often prevent major issues and costly repairs down the line.

- Inspect the air filter periodically and replace it as needed to keep the engine running smoothly.

- Ensure oil changes are done on schedule to protect the engine from excessive wear.

- Keep the blades sharp to ensure clean and precise cuts, reducing strain on the machine.

- Regularly check tire pressure to avoid uneven wear and enhance maneuverability.

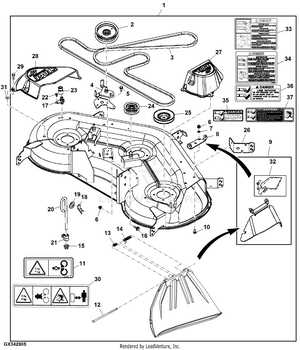

- Clean the underside of the deck to prevent debris buildup, which can cause corrosion or hinder performance.

- Lubricate all moving parts to minimize friction and extend their operational efficiency.

By incorporating these practices into your routine, you can ensure that your machine remains in top condition, providing reliable performance over an extended period.

Troubleshooting Common Issues

Dealing with mechanical equipment can occasionally lead to challenges that require immediate attention. Identifying potential faults early and knowing the basic steps to address them is key to maintaining smooth operation. Below are some frequent complications and ways to resolve them effectively.

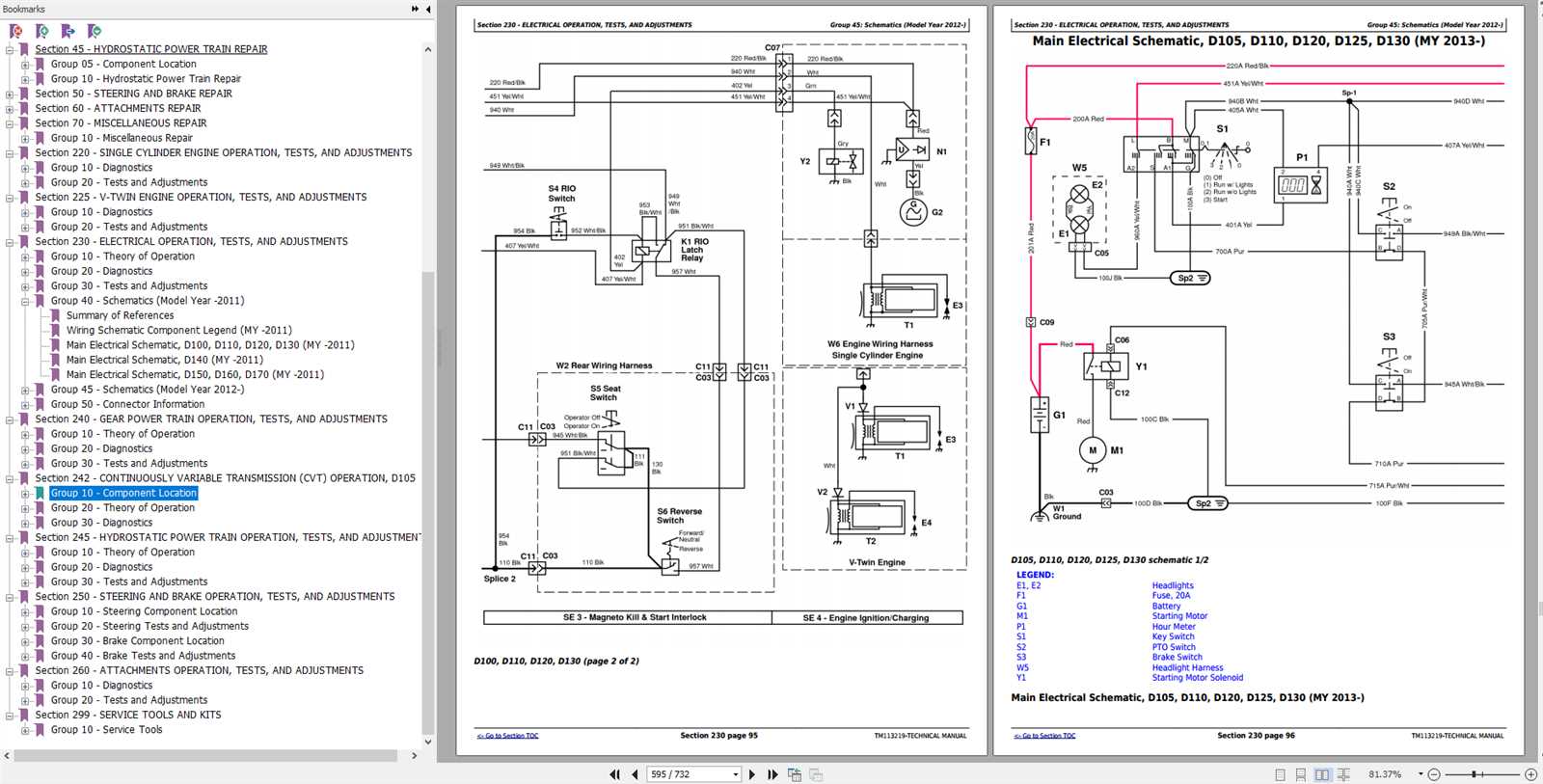

- Engine not starting: Begin by checking the power source and inspecting the ignition system. Ensure that all cables are properly connected and the battery is sufficiently charged.

- Poor cutting performance: Dull or damaged blades are often the cause. Regular sharpening or replacement is essential for efficient operation. Also, check for any obstruction in the cutting deck.

- Uneven cuts: If you notice an inconsistent grass height, ensure the cutting deck is level. Adjust the deck as needed, and inspect the wheels for proper alignment.

- Machine overheating: Blocked airflow or dirty filters can contribute to overheating. Make sure to clean the air intake and replace filters regularly to maintain adequate ventilation.

By addressing these common issues promptly, equipment reliability and performance can be sustained, minimizing downtime and ensuring optimal functionality.