Maintaining a high-performance lawn care machine is essential for achieving optimal results in landscaping. A well-structured resource can significantly enhance your understanding of this powerful tool, ensuring efficient operation and longevity.

Understanding the intricacies of your equipment allows for informed decision-making, from routine maintenance to troubleshooting. With the right information, you can enhance your skills and maximize the machine’s capabilities.

In this guide, we will delve into the essential features and functions of your lawn care device, providing the ultimate insights to help you navigate its use. Whether you’re a novice or an experienced user, the knowledge gained here will empower you to take full advantage of your equipment.

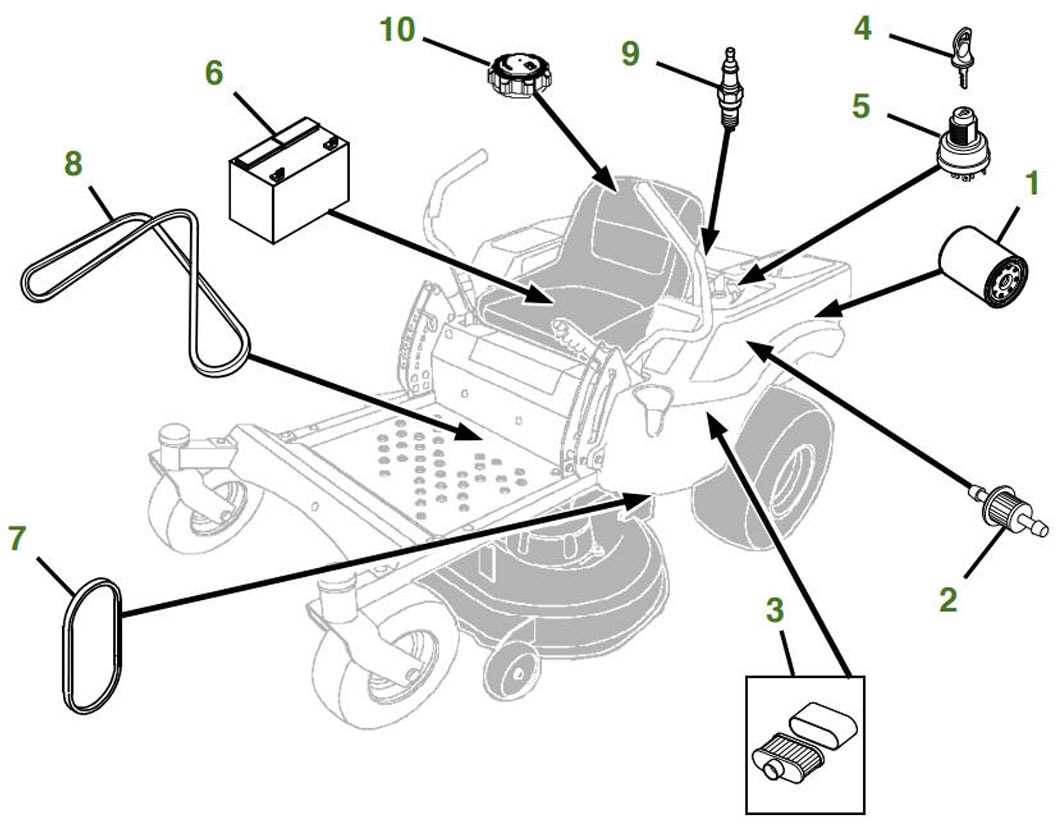

Essential Features of John Deere Z540M

This section explores the fundamental attributes of a popular mowing machine, highlighting its performance, efficiency, and user-friendly design. These elements are crucial for both residential and commercial applications, ensuring optimal results with every use.

One standout aspect is the robust engine, which provides ample power for tackling various terrains. Coupled with a high-capacity cutting deck, it ensures a clean and precise cut, enhancing the overall mowing experience.

The intuitive controls are designed for ease of use, allowing operators to maneuver effortlessly, even in tight spaces. This feature greatly reduces operator fatigue and increases productivity.

Additionally, the machine boasts superior durability, with high-quality materials that withstand the rigors of frequent use. This longevity makes it a worthwhile investment for those seeking reliability in their landscaping endeavors.

Lastly, maintenance features are streamlined, simplifying upkeep tasks and ensuring the equipment remains in peak condition over time. This focus on user convenience ultimately contributes to a seamless mowing experience.

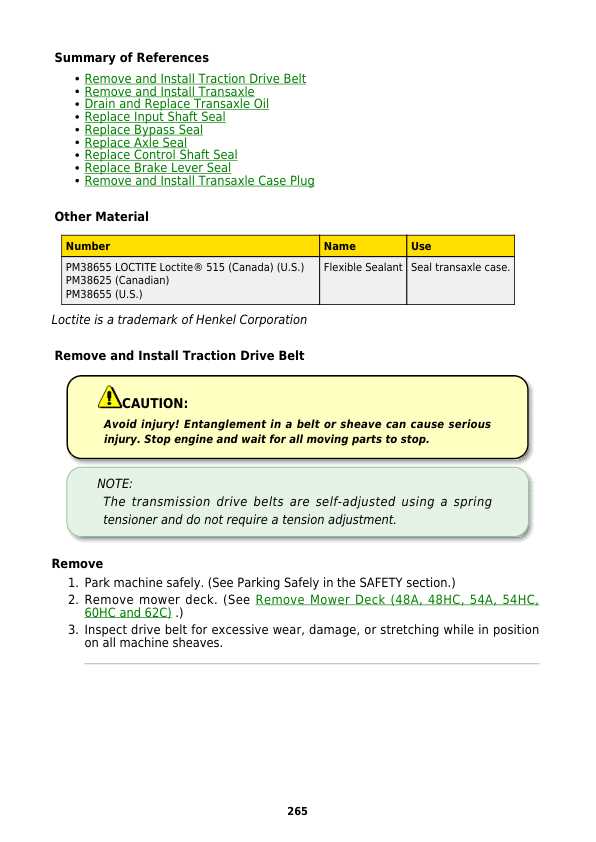

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. Regular attention to maintenance tasks can prevent costly repairs and extend the lifespan of your machinery. Following a structured maintenance routine is key to achieving optimal performance.

1. Regular Inspections: Conduct routine checks to identify any wear or damage. Look for signs of rust, loose components, or leaks. Early detection can prevent more serious issues.

2. Clean Air Filters: Keep air filters clean and free of debris. This improves airflow and ensures that the engine runs efficiently. Replace filters as recommended in your guidance documentation.

3. Check Fluid Levels: Monitor engine oil, coolant, and fuel levels regularly. Keeping fluids at proper levels is crucial for maintaining engine performance and preventing overheating.

4. Blade Maintenance: Sharpen blades regularly to ensure a clean cut. Dull blades can strain the engine and lead to uneven results. Check for damage and replace if necessary.

5. Battery Care: Inspect battery connections and terminals for corrosion. Clean them to maintain a strong electrical connection, ensuring reliable starts and efficient operation.

6. Store Properly: If storing equipment for an extended period, clean it thoroughly, empty fuel tanks, and cover it to protect against environmental elements. Proper storage helps prevent deterioration.

By incorporating these practices into your routine, you can enhance the performance and lifespan of your equipment, ensuring it remains reliable for years to come.

Understanding Safety Precautions

Prioritizing safety is crucial when operating machinery to prevent accidents and ensure a secure environment. Awareness of potential hazards and adherence to recommended guidelines can significantly reduce risks.

- Always wear appropriate personal protective equipment (PPE).

- Ensure that the workspace is clear of obstacles.

- Read and comprehend the safety labels and instructions.

In addition to personal precautions, consider the following:

- Inspect the equipment before each use.

- Keep hands and feet clear of moving parts.

- Never operate machinery under the influence of substances.

By integrating these safety measures, operators can create a safer working experience while maximizing efficiency and productivity.