Understanding your machinery is essential for maximizing performance and ensuring longevity. This section provides invaluable insights into the essential aspects of operating and maintaining your equipment effectively. With clear instructions and practical tips, users can navigate various functions with confidence.

Having access to detailed information empowers operators to troubleshoot issues, enhance productivity, and uphold safety standards. Whether you are a seasoned user or new to the world of compact machinery, this resource is designed to support your journey. It covers everything from daily maintenance routines to advanced operational techniques, ensuring that you can make the most of your investment.

As you delve into the specifics, you’ll discover the significance of routine checks and proper handling. With a focus on efficiency and safety, this guide aims to equip you with the knowledge necessary for optimal performance in any setting.

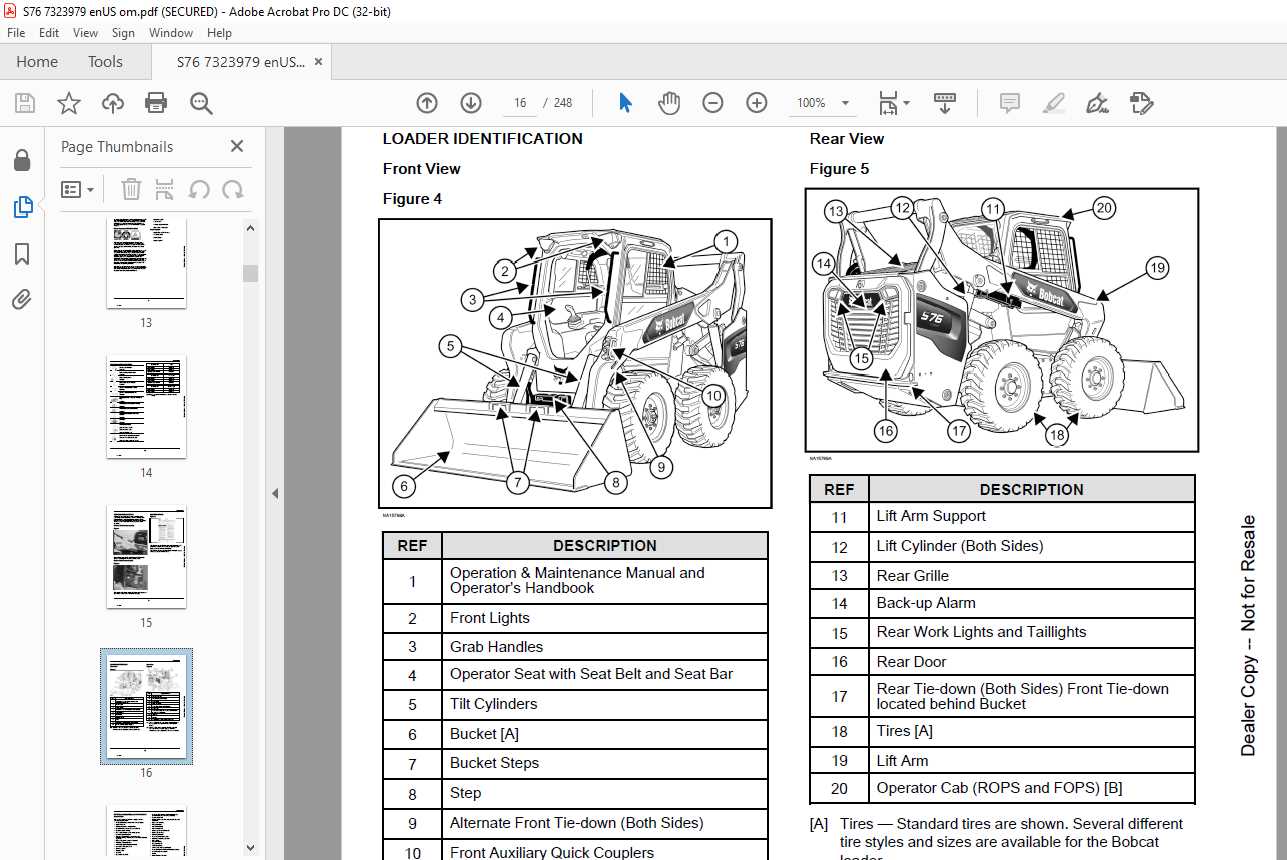

Essential Features of the Bobcat S76

The compact machine in focus is designed to deliver outstanding performance and versatility across various tasks. With its robust build and innovative engineering, this equipment caters to a wide range of applications, making it a valuable asset for operators seeking efficiency and reliability.

Performance and Efficiency

Equipped with a powerful engine, this unit excels in delivering exceptional torque and speed, ensuring optimal productivity even in challenging conditions. The advanced hydraulic system enhances lifting capabilities and allows for smooth operation, enabling users to tackle demanding jobs with ease.

Operator Comfort and Control

The interior of the cab is thoughtfully designed to enhance user experience, featuring ergonomic controls and ample visibility. Operators can easily navigate their tasks, thanks to the intuitive layout that prioritizes comfort and efficiency. Additionally, the low noise levels contribute to a pleasant working environment, allowing for extended operation without fatigue.

Maintenance Tips for S76 Owners

Proper upkeep of your compact loader is essential for ensuring optimal performance and longevity. Regular attention to specific areas can significantly reduce wear and tear, preventing costly repairs and downtime.

- Check fluid levels regularly, including hydraulic oil, engine oil, and coolant. Maintaining proper levels is crucial for efficient operation.

- Inspect the filters and replace them as needed. Clean filters contribute to the overall health of the machine and improve efficiency.

- Examine the tires for wear and correct inflation. Proper tire maintenance enhances traction and stability.

- Clean the machine frequently to remove dirt, debris, and residue. This practice not only keeps it looking good but also prevents buildup that could cause issues.

Additionally, consider scheduling periodic professional inspections to identify potential issues before they escalate. By prioritizing maintenance, you can enjoy a smoother and more reliable experience.

Operating Guidelines for Optimal Performance

To ensure peak efficiency and longevity of your machinery, it is essential to follow certain operational practices. These guidelines serve as a foundation for effective use, helping to maintain performance while minimizing wear and tear.

- Regular Maintenance: Schedule consistent inspections to identify any potential issues before they escalate. This includes checking fluid levels, filters, and belts.

- Proper Loading: Adhere to weight limits and ensure balanced distribution of materials to prevent strain on components.

- Appropriate Speed: Operate at recommended speeds for various tasks to avoid unnecessary stress on the engine and drivetrain.

- Environmental Considerations: Be mindful of the working environment. Avoid operations in extreme conditions, which can affect performance and safety.

Implementing these practices will not only enhance the efficiency of your equipment but also contribute to safer operations and extended service life.