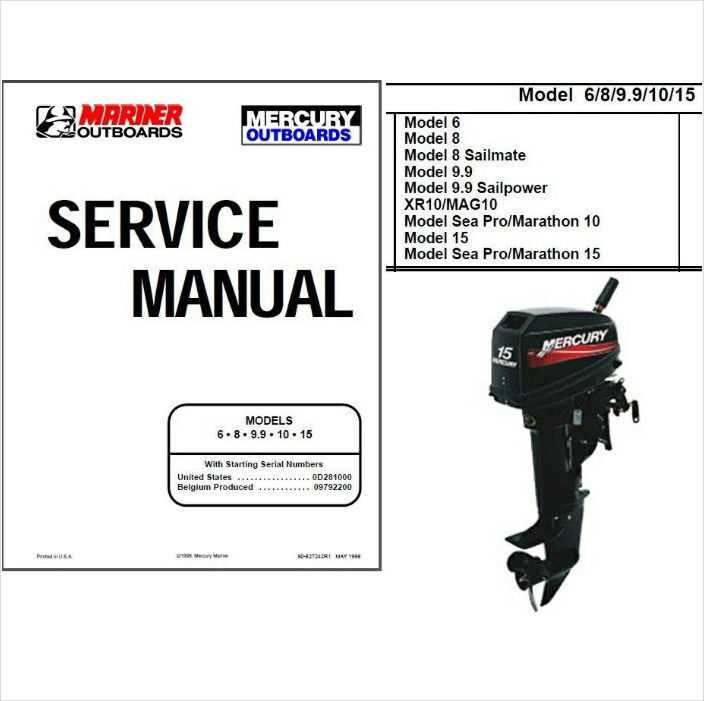

Understanding the nuances of your 8 hp propulsion system is essential for ensuring its peak performance and longevity. This guide provides a thorough overview, covering every aspect you need to know, from regular maintenance to troubleshooting common issues. Whether you’re a seasoned operator or just starting, having a detailed understanding of your equipment is crucial for smooth sailing experiences.

The content here focuses on providing practical insights into the setup, routine care, and operational tips for your compact engine. You’ll discover essential steps for handling, maintaining, and optimizing its performance in various conditions. By familiarizing yourself with the key functions, you can ensure that your device remains reliable during every adventure.

Embrace this detailed resource to gain confidence in handling your marine propulsion device, ensuring you’re well-prepared for every journey. Let this guide be your companion in unlocking the full potential of your marine engine, giving you more time to enjoy the waters ahead.

Maintenance Tips for Long-Lasting Performance

Ensuring the longevity of your watercraft’s propulsion system requires regular upkeep and attention to detail. By following a consistent care routine, you can significantly extend the lifespan of your equipment and maintain optimal functionality throughout your journeys.

1. Regular Inspection and Cleaning

Frequent checks of the propeller and other critical components help identify potential issues before they become major problems. After each use, rinse the entire system with fresh water to remove any salt, dirt, or debris that may cause corrosion or damage over time.

2. Lubrication and Fluid Levels

Keeping all moving parts well-lubricated is crucial for smooth operation. Regularly check the fluid levels, including oil and fuel, and replace them according to the manufacturer’s recommendations. Using high-quality lubricants ensures reduced friction, preventing unnecessary wear and tear on the engine.

Routine Checks to Avoid Common Issues

Regular inspections are essential to ensure the smooth operation and longevity of your marine engine. By dedicating time to simple maintenance tasks, you can prevent many common malfunctions and keep your equipment running efficiently.

Inspecting Fuel Lines and Connections

Fuel lines can deteriorate over time due to exposure to the elements, leading to cracks or leaks. It’s crucial to examine these lines periodically, checking for any visible wear or loose connections. Replace any damaged parts immediately to avoid unexpected breakdowns.

Monitoring Lubrication Levels

A well-lubricated engine runs more smoothly and reduces the risk of overheating. Make it a habit to check lubrication levels before each use. This practice not only helps in avoiding potential damage but also ensures optimal performance on the water.

| Check | Description | Frequency |

|---|---|---|

| Fuel Line Inspection | Examine for cracks, leaks, and wear. | Monthly |

| Lubrication Check | Ensure appropriate lubrication levels. | Before Each Use |

| Propeller Assessment | Inspect for dents, fishing lines, or debris. | Every 3 Months |

Engine Troubleshooting for Smooth Operation

Achieving reliable performance from your small motorized vessel requires addressing common operational challenges. This section outlines essential techniques to maintain efficiency, ensuring the engine runs seamlessly.

Identifying Start-Up Issues

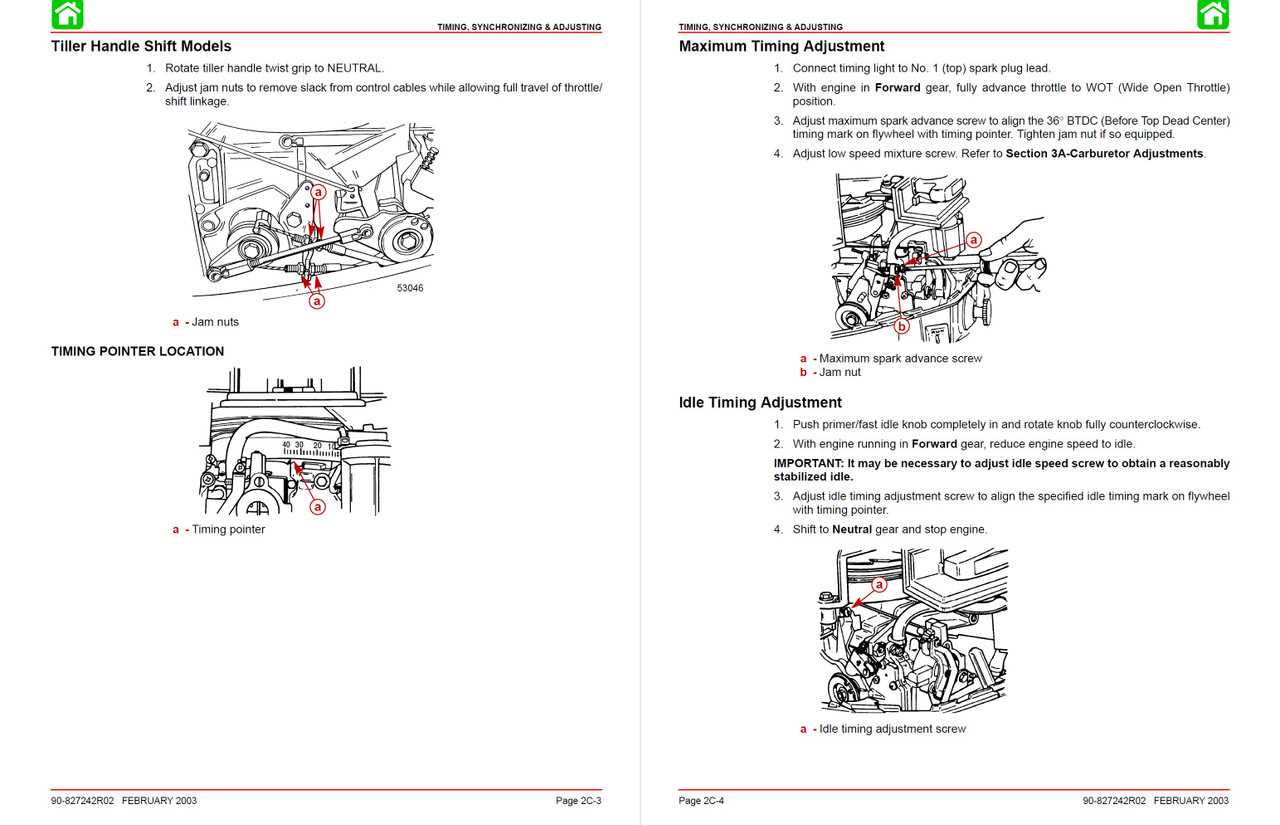

If the motor struggles to start, it may be due to a lack of fuel flow or spark. Begin by checking the fuel lines for any blockages or air leaks. Ensure the connections are secure and inspect the fuel for any impurities. Inadequate spark can also cause issues, so examine the spark plugs for signs of wear or fouling. Cleaning or replacing them can significantly improve ignition.

Addressing Power Loss and Rough Idling

When experiencing a reduction in power or inconsistent running, clogged fuel filters or dirty carburetors might be to blame. Regularly clean the filters and carburetor components to prevent fuel flow obstructions. Additionally, inspect the air intake system, as restricted airflow can cause uneven engine operation. A well-maintained cooling system is crucial for smooth performance; always ensure water passages are clear of debris to prevent overheating.

Identifying and Resolving Starting Problems

Understanding the reasons behind starting issues is crucial for maintaining smooth operation. This section will guide you through common causes and solutions to help troubleshoot and fix problems related to engine ignition.

| Possible Cause | Description | Recommended Action |

|---|---|---|

| Fuel System Issues | Old or contaminated fuel, clogged filters, or an empty tank can prevent the motor from starting. | Inspect the fuel line, replace filters if needed, and ensure fresh fuel is used. |

| Spark Plug Problems | Worn-out, dirty, or improperly gapped spark plugs can hinder ignition. | Check and clean or replace the spark plugs, ensuring the correct gap. |

| Battery Failure | A weak or dead battery might cause ignition failure. | Test the battery charge, clean connections, and replace if necessary. |

| Choke Adjustment | Improper choke settings can affect the fuel mixture, leading to starting difficulties. | Adjust the choke to match current temperature conditions for optimal starting. |

| Blocked Air Intake | Obstructions in the air intake can restrict airflow, making it hard to start. | Inspect the intake area and remove any debris or blockages. |

Seasonal Storage and Preparation

Properly preparing and storing your small engine-driven watercraft is essential for ensuring smooth operation when it’s time to return to the water. Taking the right steps before long-term storage can prevent potential damage and make the reactivation process much easier.

Steps for Preparing for Winter

- Begin by flushing the cooling system with fresh water to remove any salt, sand, or debris.

- Drain any remaining fuel from the tank and lines to prevent gumming or clogging.

- Add a fuel stabilizer if fuel remains, ensuring all parts of the system are treated.

- Apply a corrosion inhibitor to metal surfaces to protect against rust during the off-season.

Spring Readiness Checklist

- Inspect all hoses, belts, and connections for any signs of wear or cracks.

- Check and replace spark plugs if needed, ensuring a reliable ignition.

- Lubricate moving parts, such as throttle cables, for smooth operation.

- Test the battery and recharge if necessary, verifying that electrical components function correctly.

Following these steps will not only extend the lifespan of your equipment but also provide a worry-free experience during the next season.