Proper care and operation of machinery are crucial for its longevity and efficient performance. Understanding the key aspects of maintaining and handling equipment can prevent unnecessary wear and ensure that it operates optimally for a long period. In this section, we will cover the essential steps needed to keep your machine running smoothly and safely.

The following guidelines will focus on maintenance procedures, regular inspections, and practical advice for resolving common issues that may arise during usage. By following these recommendations, you can improve the overall lifespan of your equipment and avoid costly repairs.

Additionally, we will provide helpful tips to ensure that your machine remains in top condition, allowing you to maximize its potential and avoid downtime. Whether you’re a new or experienced operator, these practices will enhance your understanding and control over the equipment’s performance.

Essential Maintenance Tips for Your Equipment

Regular upkeep is key to ensuring that your machinery remains efficient and reliable over time. A well-maintained piece of equipment can offer consistent performance, reduce downtime, and extend its operational lifespan. Below are some fundamental practices to help you maintain your machinery in top condition, ensuring it runs smoothly for years to come.

Keep Components Clean

One of the simplest yet most effective ways to maintain your equipment is by keeping all parts free from dirt, dust, and debris. Regular cleaning can prevent wear and tear, ensuring that all components function without unnecessary strain. Pay particular attention to air filters, cooling systems, and any moving parts that may accumulate grime during operation.

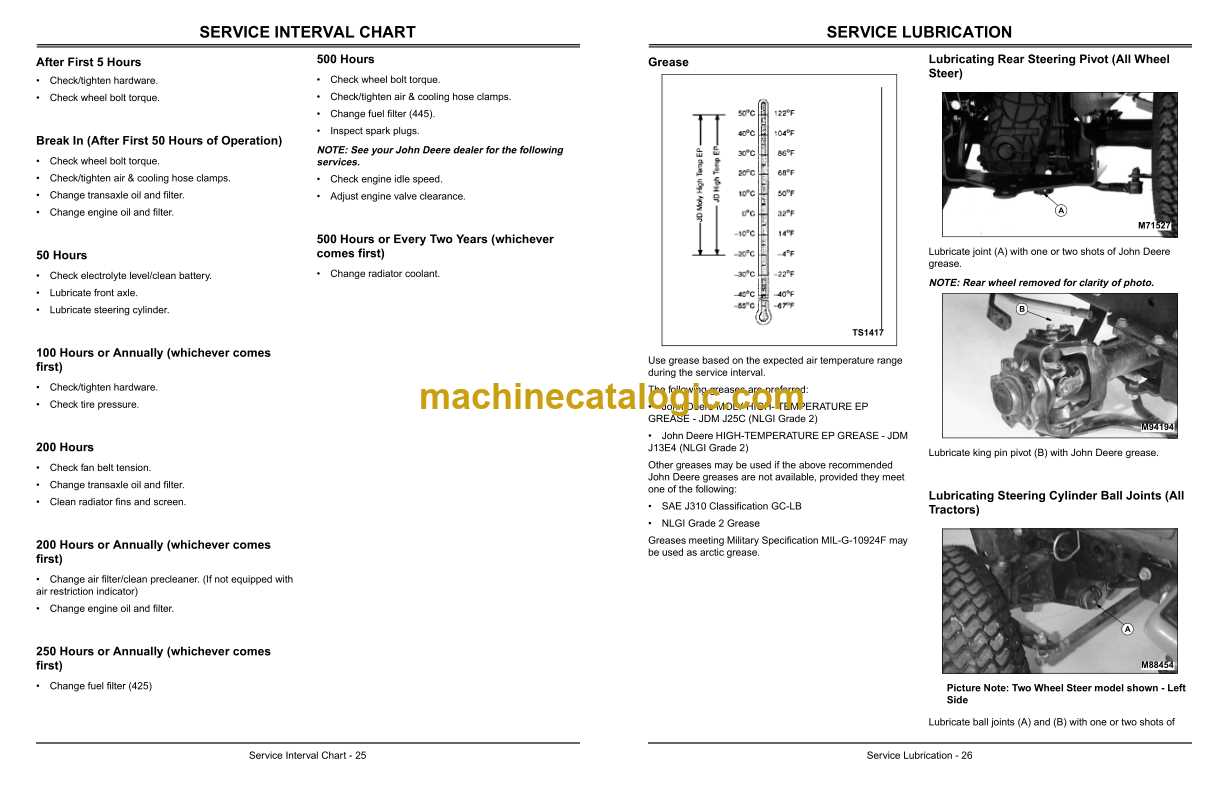

Follow a Routine Lubrication Schedule

Proper lubrication reduces friction between moving parts, preventing excessive wear. Establishing a consistent lubrication routine is essential for avoiding unnecessary breakdowns. Always use the correct type of oil or grease, as specified by the manufacturer, and inspect seals and joints regularly to avoid leaks or contamination.

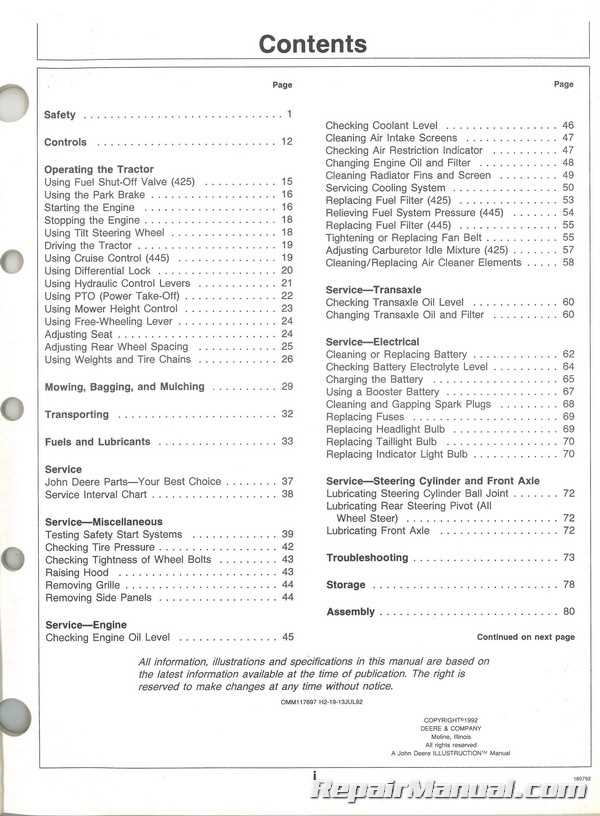

Troubleshooting Common Issues and Repairs

Identifying and resolving frequent problems is crucial for maintaining the efficiency of equipment. This section provides guidance on recognizing typical malfunctions and implementing basic fixes to keep machinery running smoothly. By understanding these issues, operators can quickly address concerns and minimize downtime.

| Problem | Possible Cause | Solution |

|---|---|---|

| Engine Won’t Start | Low fuel levels, dead battery, or faulty ignition | Check fuel supply, recharge or replace the battery, inspect the ignition system |

| Overheating | Clogged cooling system or insufficient coolant | Clean the cooling system, refill coolant levels |

| Uneven Cutting | Dull blades or improper deck adjustment | Sharpen or replace blades, adjust the cutting deck height |

| Loss of Power | Clogged air filter or fuel line obstruction | Replace the air filter, clear any blockages in the fuel line |

| Strange Noises | Loose or worn components | Tighten or replace worn parts as needed |

Prolonging the Lifespan of Your Machine

Maintaining your equipment properly is crucial to ensure it performs efficiently for years. Regular attention to its components, timely servicing, and mindful usage can significantly extend the life of any machine, making it more reliable and cost-effective in the long run. By adopting a consistent maintenance routine, you reduce the risk of breakdowns and improve its overall performance.

Routine Maintenance

- Check fluid levels regularly, including oil and coolant, to prevent engine wear.

- Inspect the air filter and clean or replace it as needed to maintain optimal engine efficiency.

- Lubricate moving parts according to the manufacturer’s guidelines to reduce friction and wear.

Proper Operation Practices

- Always operate the machine within its recommended load capacity to avoid unnecessary strain.

- Warm up the engine before use, especially in colder weather, to prevent sudden temperature changes that may damage components.

- Store the machine in a dry, sheltered area to protect it from environmental factors that can cause rust or damage.