This section aims to provide comprehensive guidance for users of a specific type of machinery, focusing on its effective utilization and maintenance. Understanding the operation and care of your device is crucial for maximizing its performance and longevity.

In the following paragraphs, you will find important information that covers various aspects, including setup instructions, troubleshooting tips, and routine maintenance practices. This knowledge will empower you to handle your equipment confidently, ensuring optimal functionality throughout its lifespan.

Equipped with the right insights, you can enhance your experience and mitigate common issues that may arise during usage. Embrace the opportunity to learn about the essential features and functionalities that make your machinery reliable and efficient.

Overview of the Air Compressor Model

This section provides a comprehensive insight into a specific air compressor model designed for various applications. It highlights the essential features, specifications, and advantages that make this equipment a valuable asset for users across different industries.

Key Features

- Robust construction ensuring durability and reliability

- Efficient performance for high-demand tasks

- User-friendly controls for easy operation

- Versatile applications in both professional and personal settings

Specifications

- Power Output: Designed to deliver optimal energy efficiency

- Pressure Range: Suitable for a variety of tasks requiring different pressure levels

- Noise Level: Engineered to operate quietly for user comfort

Understanding these aspects allows potential users to make informed decisions regarding the suitability of this air compressor for their specific needs.

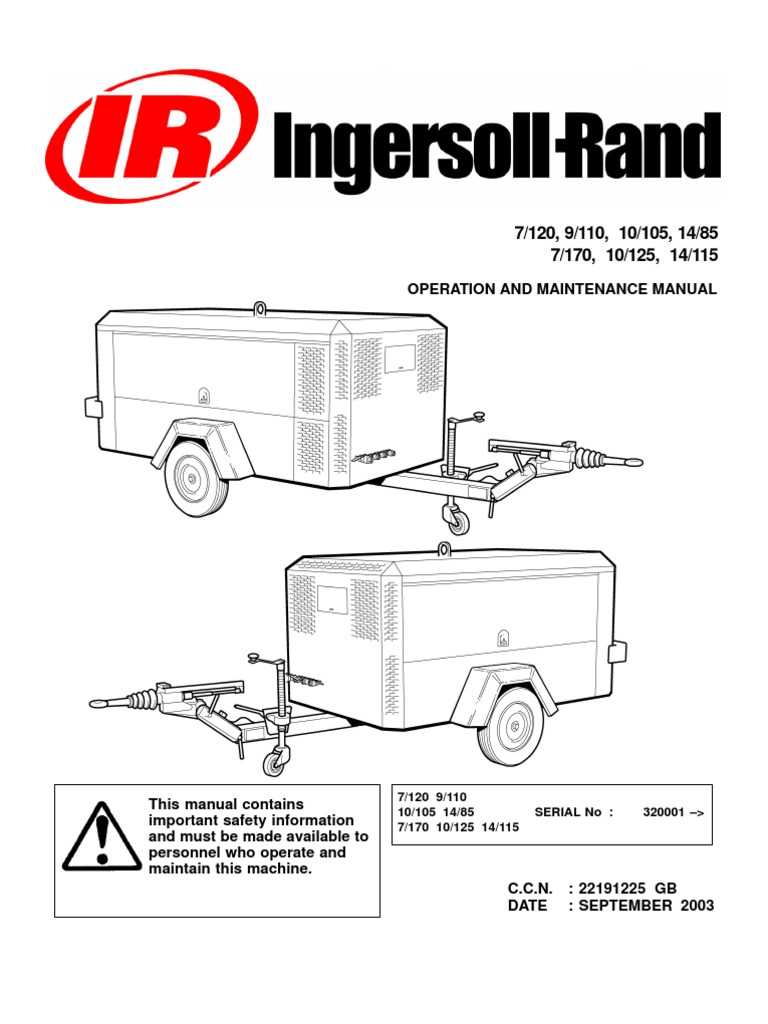

Key Features and Specifications

This section outlines the essential characteristics and technical details of the device, emphasizing its capabilities and operational advantages. Understanding these aspects is crucial for users to maximize the performance and efficiency of the equipment.

Notable Features

- Robust design for enhanced durability

- High operational efficiency to minimize energy consumption

- Versatile applications across various industries

- Intuitive interface for ease of use

- Integrated safety mechanisms to protect users

Technical Specifications

- Power Source: Electric

- Maximum Pressure: 150 PSI

- Flow Rate: 12 CFM

- Weight: 150 lbs

- Dimensions: 36 x 18 x 30 inches

Maintenance and Care Guidelines

Proper upkeep and attention are essential for ensuring optimal performance and longevity of equipment. By adhering to recommended practices, users can effectively prevent issues and maintain efficient operation over time.

Routine Inspections

Regular checks are vital for identifying any potential problems early on. Look for signs of wear and tear, loose components, or unusual noises during operation. Addressing these issues promptly can prevent more significant malfunctions.

Cleaning and Lubrication

Keeping the machinery clean is crucial. Remove any debris or dust that may accumulate, as this can hinder performance. Additionally, apply suitable lubricants to moving parts to ensure smooth operation and reduce friction.

| Task | Frequency | Notes |

|---|---|---|

| Inspect components | Weekly | Check for signs of damage or wear. |

| Clean exterior | Monthly | Remove dust and debris to maintain appearance and function. |

| Lubricate moving parts | Every three months | Use recommended lubricants for best results. |

| Check fluid levels | Monthly | Ensure all fluids are at optimal levels. |

Troubleshooting Common Issues

This section aims to provide guidance for resolving frequent problems encountered with the equipment. Understanding potential malfunctions can greatly enhance operational efficiency and prolong the lifespan of the device.

Identifying Performance Problems

When the device fails to operate as expected, it is essential to check for simple issues such as power supply disruptions, loose connections, or incorrect settings. Ensuring that all components are securely attached and functioning can often resolve many basic concerns.

Addressing Unusual Noises

Unusual sounds during operation may indicate underlying mechanical issues. Inspecting for debris, worn parts, or inadequate lubrication can help pinpoint the source of the noise. Regular maintenance can prevent such problems from arising.