This section aims to provide essential insights and guidance for individuals seeking to maximize the functionality of their agricultural equipment. With a focus on practical usage, it covers various aspects that contribute to efficient operation.

Understanding the key features and maintenance practices of your machinery is crucial for optimal performance. This guide will navigate through the necessary steps to ensure longevity and reliability, enabling users to harness the full potential of their equipment.

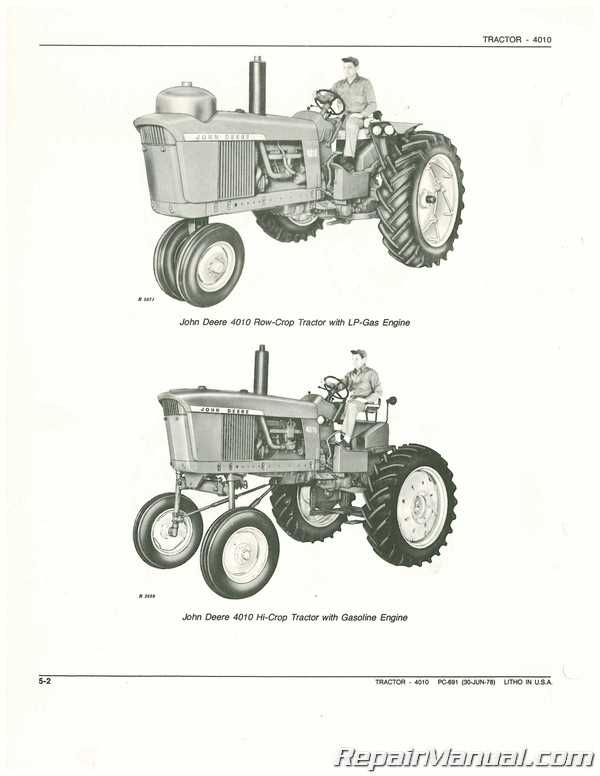

Key Features of the John Deere 4010

This section explores the remarkable attributes of a well-known agricultural vehicle, highlighting its efficiency, versatility, and user-friendly design. Understanding these features can enhance operational performance and maintenance practices.

Efficiency and Power

- Robust engine capabilities ensure reliable performance across various terrains.

- Fuel efficiency contributes to lower operational costs over time.

User-Friendly Design

- Intuitive controls facilitate ease of use for operators of all skill levels.

- Comfortable seating and ergonomic layout reduce operator fatigue during long hours of work.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure the longevity and efficiency of your machinery. By implementing a systematic approach to maintenance, you can enhance performance and prevent potential issues before they arise.

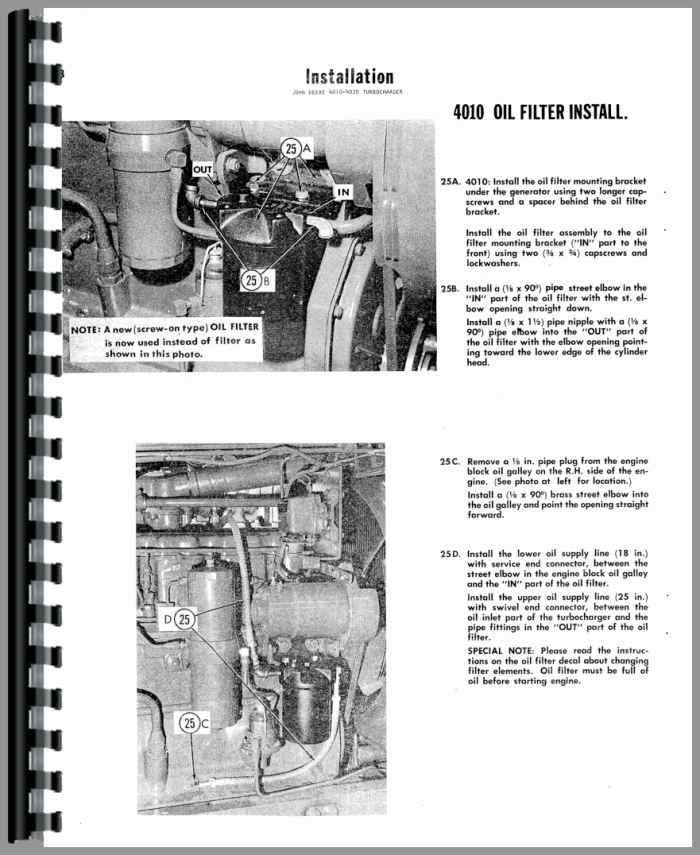

1. Routine Inspections: Conduct periodic checks of all essential components to identify wear or damage early. Focus on key areas such as belts, filters, and fluid levels.

2. Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and minimizes wear, which can significantly prolong the life of your equipment.

3. Cleanliness: Keep the machine clean to prevent dirt and debris from causing blockages or damage. Regular washing can help maintain optimal performance.

4. Follow Manufacturer Guidelines: Adhere to the recommended service intervals and procedures provided by the manufacturer for the best results.

5. Use Quality Parts: When replacements are necessary, opt for high-quality parts that meet or exceed original specifications to maintain efficiency.

Common Issues and Troubleshooting Guide

This section aims to provide helpful insights into frequently encountered problems and their solutions, ensuring optimal performance of your equipment. By understanding these common challenges, users can effectively troubleshoot and maintain their machinery.

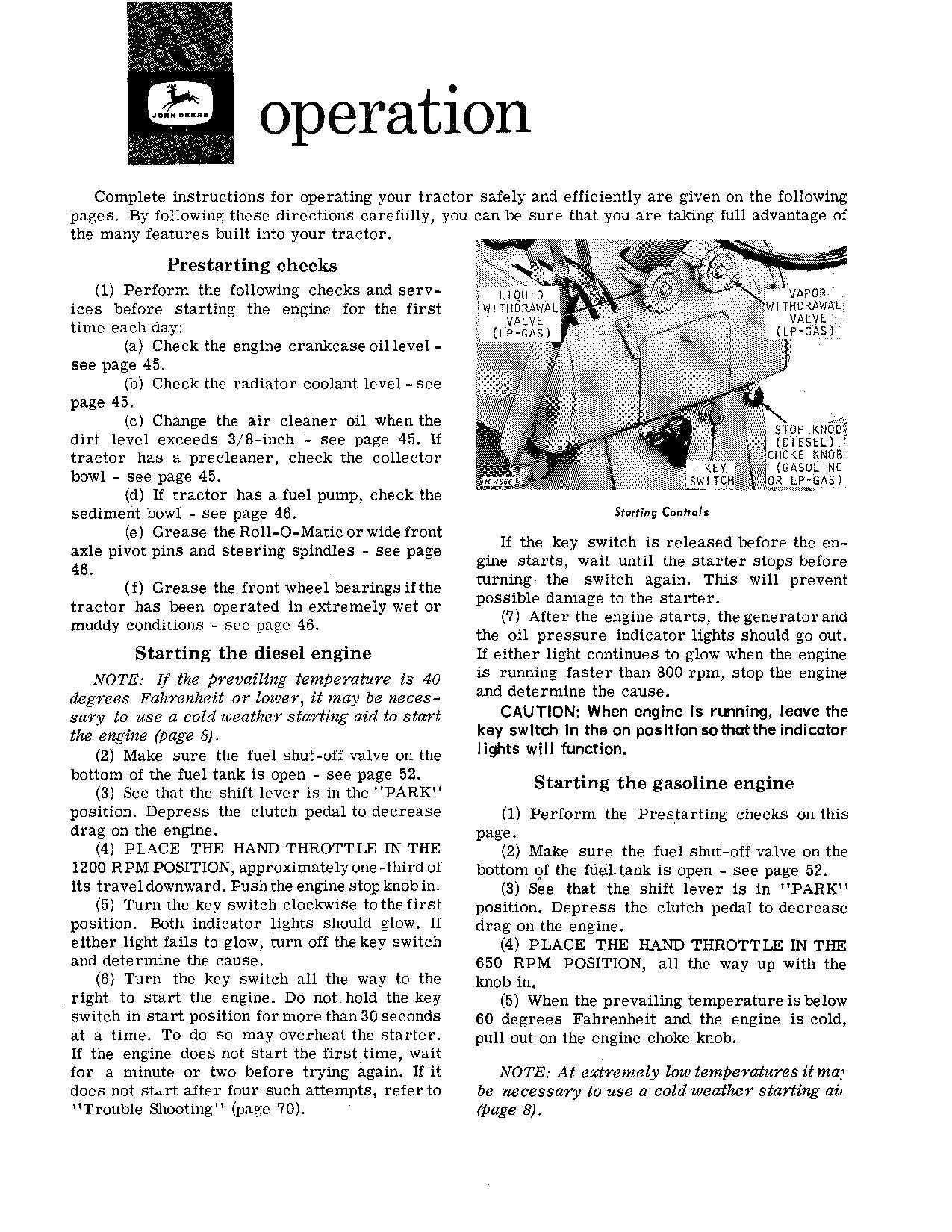

- Engine Won’t Start

- Check fuel levels and quality.

- Inspect the battery connections for corrosion.

- Examine the ignition system for faults.

- Hydraulic Issues

- Look for leaks in hydraulic lines.

- Ensure the hydraulic fluid is at the proper level.

- Check the pump for any unusual sounds.

- Overheating

- Verify coolant levels and quality.

- Inspect the radiator for blockages.

- Ensure the fan is functioning properly.

- Electrical Failures

- Examine fuses for any breaks.

- Check wiring for wear and damage.

- Test switches and relays for functionality.