This section aims to provide invaluable insights for individuals utilizing their lawn maintenance equipment. It encompasses crucial operational guidelines, safety precautions, and best practices to ensure optimal performance.

Understanding the intricacies of your machine can greatly enhance its functionality and longevity. By familiarizing yourself with the various components and features, you will be better equipped to tackle lawn care tasks effectively and efficiently.

Whether you are a seasoned user or new to the realm of garden machinery, this guide serves as a comprehensive resource, helping you navigate the essential aspects of maintenance and operation. Embrace the opportunity to maximize your equipment’s potential and enjoy a well-kept outdoor space.

Understanding Your John Deere L111

This section aims to provide insight into the essential features and functionalities of your equipment. Familiarizing yourself with these aspects will enhance your operational efficiency and maintenance practices.

Key Features to Explore

Discover the various components designed to optimize performance. From the engine to the cutting system, each element plays a vital role in ensuring effective operation.

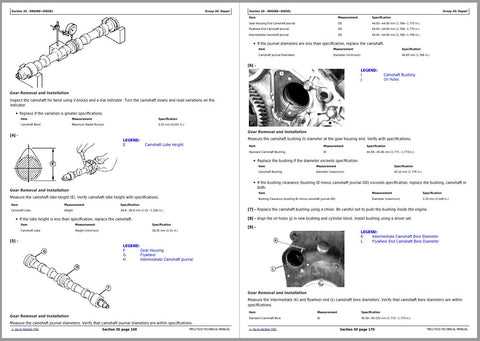

Maintenance Essentials

Regular upkeep is crucial for longevity. Learn about routine checks and servicing tasks that will keep your machine running smoothly and effectively.

Essential Maintenance Tips for Longevity

To ensure the prolonged performance and efficiency of your equipment, regular upkeep is crucial. By adhering to a structured maintenance routine, owners can prevent common issues and enhance the lifespan of their machinery.

Regular Inspections

Conducting frequent checks helps identify potential problems early. Look for signs of wear, leaks, or unusual noises that may indicate the need for repair.

Proper Cleaning

Keeping the exterior and interior clean is vital. Remove debris and dirt after each use to prevent build-up that could affect functionality. Utilizing the right cleaning agents can also help maintain surfaces and components in optimal condition.

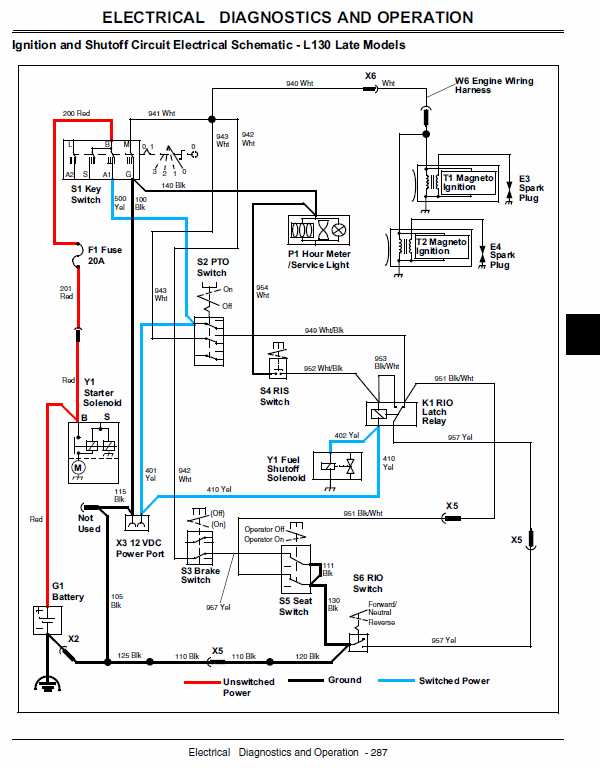

Common Troubleshooting Techniques Explained

Troubleshooting equipment can be a straightforward process when employing effective strategies. Identifying common issues and applying systematic approaches often leads to successful resolutions. Understanding these techniques empowers users to maintain their machines efficiently and prevent further complications.

Identifying the Problem

Begin by observing the symptoms. Is there an unusual noise, lack of power, or other noticeable changes? Documenting these details can provide valuable insights when seeking solutions. Gather information about the situation, including any recent changes made to the device.

Systematic Approach

Utilize a step-by-step method for troubleshooting. Start with the most obvious causes, such as checking fuel levels or electrical connections. If the issue persists, progressively investigate deeper into the system components. This method ensures that no potential cause is overlooked, leading to effective problem resolution.