Owning a high-performance cleaning device can significantly enhance your cleaning efficiency and effectiveness. These machines are designed to tackle tough grime and dirt, making them an invaluable addition to your maintenance toolkit. Understanding how to operate and care for your equipment will ensure you get the most out of your investment, maximizing both longevity and performance.

In this section, we will delve into essential information that every user should be aware of when utilizing this type of machinery. From safety precautions to routine maintenance tips, our goal is to provide comprehensive insights that empower you to handle your device with confidence. This knowledge will not only help you achieve superior cleaning results but also ensure your equipment remains in excellent working condition for years to come.

Equipped with the right techniques and an understanding of your machine’s features, you can efficiently manage a variety of cleaning tasks around your home or workspace. Whether you’re tackling stubborn stains on driveways or refreshing outdoor furniture, being well-informed will lead to better outcomes and a more satisfying experience overall.

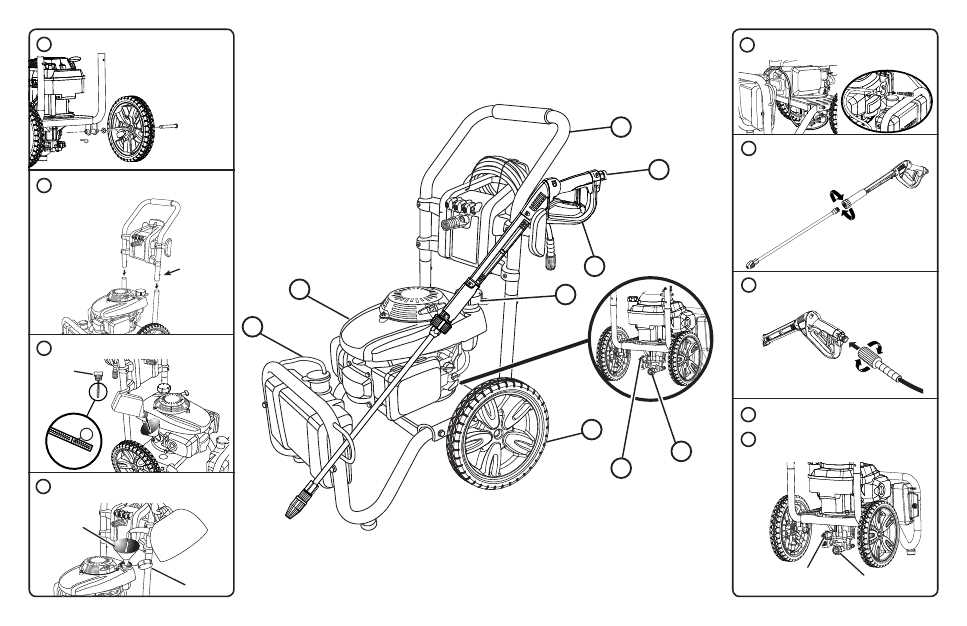

Essential Features of the Ryobi Pressure Washer

When it comes to efficient cleaning solutions, having a reliable unit is crucial for tackling a variety of tasks. This particular model stands out due to its blend of power, convenience, and innovative design. Understanding its key attributes can significantly enhance the user experience and ensure optimal performance.

- Powerful Motor: Equipped with a robust motor, this unit delivers impressive cleaning capabilities, making it ideal for tackling tough grime and stains on various surfaces.

- Adjustable Nozzle: The inclusion of an adjustable nozzle allows users to switch between different spray patterns, providing versatility for different cleaning applications, from gentle rinsing to intense scrubbing.

- Easy Mobility: Designed with portability in mind, it features lightweight construction and wheels, enabling easy movement around the workspace without hassle.

- Durable Construction: Built with high-quality materials, this model promises longevity and resilience, ensuring it can withstand regular use without compromising performance.

- Quick Connect System: The quick connect system simplifies the setup process, allowing users to effortlessly attach hoses and nozzles, minimizing downtime.

These features collectively enhance the functionality and usability of the unit, making it a valuable addition to any cleaning toolkit. Investing in such a model ensures efficient performance, ultimately leading to cleaner and more polished surfaces.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your cleaning equipment operates at its best. By implementing a consistent maintenance routine, you can extend the lifespan of your device, enhance its efficiency, and improve overall functionality. This section provides valuable insights into the best practices for maintaining your equipment, helping you achieve the best results with every use.

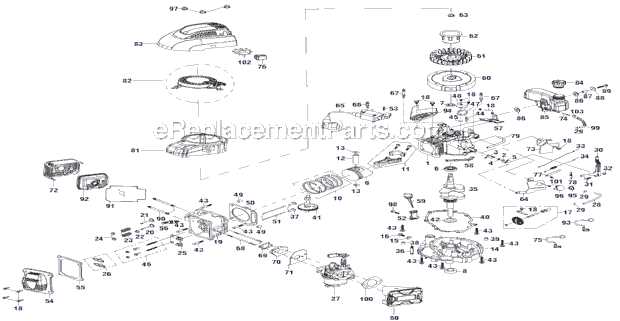

Routine Inspection

Conducting frequent inspections of your cleaning device can help identify potential issues before they escalate. Focus on the following components during your checks:

| Component | Inspection Checklist |

|---|---|

| Hoses | Look for cracks, leaks, or signs of wear. |

| Nozzles | Ensure they are clear of debris and functioning properly. |

| Filter | Check for clogs and clean or replace as necessary. |

| Connections | Verify that all fittings are secure and tight. |

Storage Practices

Proper storage plays a crucial role in maintaining your device’s performance. When not in use, consider the following guidelines:

- Store in a cool, dry place to prevent rust and corrosion.

- Avoid direct sunlight, which can degrade materials over time.

- Disconnect all hoses and attachments to prevent damage.

Common Issues and Troubleshooting Guide

This section provides essential insights into frequent problems encountered with high-pressure cleaning devices and effective strategies for resolving them. Understanding these common challenges can help users maintain optimal performance and extend the lifespan of their equipment.

Device Fails to Start: One of the most prevalent issues is the failure to activate the device. Ensure that the power source is functional, and check for any tripped circuit breakers or blown fuses. Additionally, inspect the power cord for any visible damage.

No Water Flow: If the machine operates but water does not flow, inspect the inlet filter for clogs and ensure that the water supply is adequate. A kinked hose can also restrict water flow, so verify that it is straight and free from obstructions.

Inconsistent Pressure: Fluctuations in cleaning intensity can arise from various factors. Start by checking the nozzle for blockages. If the nozzle is clear, examine the pump for potential leaks or damage, as these can lead to pressure drops.

Leaks: Fluid leaks can indicate worn or damaged seals and hoses. Inspect all connections and components for signs of wear. Replacing any damaged parts promptly can prevent further complications and ensure proper operation.

Unusual Noises: If the device emits strange sounds during operation, it may signal an internal issue. Turn off the unit and inspect for loose components or foreign objects within the housing. Regular maintenance checks can help identify potential problems before they escalate.

By addressing these common challenges and following the suggested solutions, users can enhance the reliability and effectiveness of their cleaning apparatus.