Welcome to the resource dedicated to helping you get the most out of your new household tool. This guide is designed to offer step-by-step instructions to assist you in setting up, operating, and maintaining your equipment. By following the outlined recommendations, you will be able to efficiently utilize all its features.

The guide covers every essential aspect, from initial setup to troubleshooting common issues. It provides tips on regular care, ensuring the longevity and performance of your tool. With clear instructions, this resource will serve as your go-to reference.

Whether you’re just starting or looking to master advanced functionalities, this section will walk you through the essential processes to make sure you’re using your tool safely and effectively. Explore each section to fully unlock the potential of your equipment.

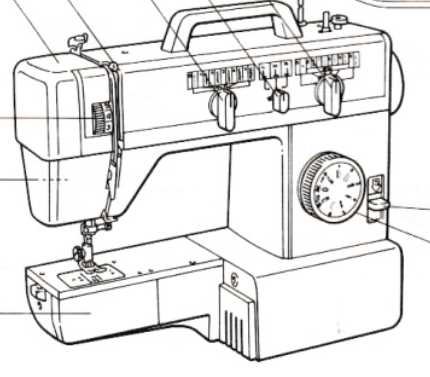

Understanding the White Sewing Machine Basics

Gaining a clear understanding of how this versatile tool operates is essential for anyone looking to begin working with fabrics. It’s important to become familiar with the key functions that enable the smooth creation of various designs. Mastering these foundational concepts allows users to work more efficiently, ensuring precision and consistency in every project.

Key Features to Explore

One of the most crucial steps is recognizing the different controls and their purposes. From adjusting the tension to selecting the right stitch, every feature plays a role in how the tool performs. Knowing how to properly set these options will make the process much more fluid.

Practical Tips

Before starting, it’s essential to ensure everything is correctly assembled. This includes loading the thread properly, adjusting settings, and performing a quick test on scrap material. Following these steps will help avoid any unnecessary challenges and ensure a smooth experience throughout.

Setting Up Your White Sewing Machine

Before starting any project, it’s essential to ensure your device is correctly assembled and ready for use. Proper preparation not only guarantees smooth operation but also extends the lifespan of your equipment. This guide will help you organize all necessary components and establish the foundation for seamless functionality.

Organizing Your Workspace

Ensure your workspace is clean and well-lit. Having all tools and accessories within reach is crucial for efficiency. Make sure the surface is stable to prevent any unwanted movement during the process.

Attaching the Necessary Parts

Each component plays a vital role in the operation. Carefully connect all pieces according to their designated positions. Align everything securely to avoid misalignment during usage.

| Component | Function |

|---|---|

| Base | Provides stability for the entire setup |

| Thread Spool Holder | Holds the thread in place during operation |

| Needle | Performs the stitching process by piercing the material |

| Foot Pedal | Controls

Maintenance Tips for Long-lasting PerformanceConsistent care and regular upkeep are key to ensuring the durability and smooth function of any mechanical device. By following a few simple guidelines, you can maximize its lifespan and maintain optimal efficiency over time. Regular CleaningOne of the easiest ways to keep a device running efficiently is through periodic cleaning. Dust, lint, and other debris can accumulate in small parts, potentially causing malfunctions. Make it a habit to clean the internal components, paying attention to areas prone to buildup. Use a soft brush or compressed air for delicate sections. Lubrication and Adjustments

Proper lubrication is essential for minimizing friction between moving parts. Apply suitable oil to the recommended areas, ensuring a smooth operation. Additionally, inspect and adjust any components that may become loose or misaligned over time to prevent unnecessary wear. Tip: Always follow guidelines on the type of lubricant required and frequency of maintenance to avoid damage. Solving Common Issues with White Sewing MachinesWhen encountering challenges during the stitching process, it’s important to remain patient and assess the situation carefully. Many common obstacles can be addressed with simple adjustments or routine maintenance. This section outlines practical solutions to help ensure smooth operation. Thread Tension Problems: If the thread appears loose or uneven, start by checking the tension settings. Both upper and lower threads should be balanced. Adjusting the dial slightly can often correct irregularities. Skipped Stitches: Skipping in the stitching can result from a dull or improperly inserted needle. Always ensure the needle is sharp and correctly positioned. Using the right type of needle for the fabric can also make a big difference. Fabric Not Feeding: If the fabric isn’t moving as expected, ensure that the feed dogs are engaged and clean. Dust and lint buildup can interfere with fabric movement. Regular cleaning will prevent this issue. Tip: Regular maintenance and correct settings are key to avoiding many of the typical challenges faced during the stitching process. Be sure to keep your equipment clean and properly adjusted for optimal performance. Fixing Threading Problems EfficientlyEnsuring smooth operation requires addressing common issues related to the proper alignment of the thread. Identifying and resolving such difficulties can save time and prevent further complications. In this section, we will explore practical methods to troubleshoot and fix these issues with precision.

By following these steps, threading issues can be quickly identified and resolved, allowing for uninterrupted use. |