This section provides essential insights into the operation and maintenance of versatile welding machines. Understanding these powerful tools is crucial for achieving optimal performance and ensuring safety during use.

By familiarizing yourself with key features and functionalities, users can enhance their welding skills and address common challenges effectively. This guide aims to equip you with the knowledge necessary for proper utilization and care of your equipment.

Explore various aspects such as setup, troubleshooting, and regular maintenance routines to ensure longevity and reliability. Harnessing the full potential of your welding equipment can lead to improved results in various projects.

Miller Bobcat 225 Overview

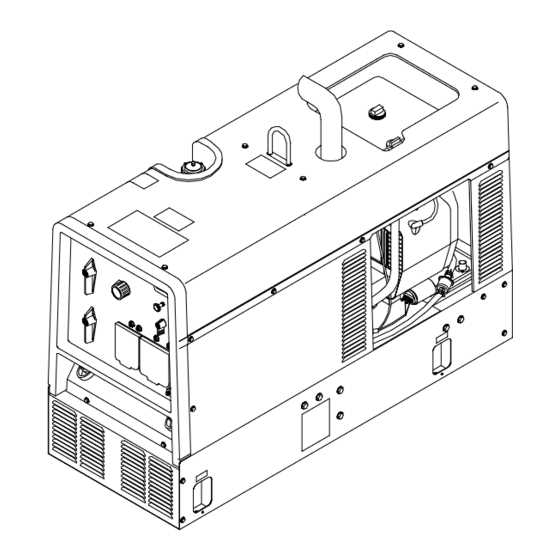

This section provides a comprehensive understanding of a portable power generator that combines versatility and efficiency. It is designed to deliver reliable energy solutions for various applications, making it suitable for both professional and recreational use.

Key Features

The device is equipped with advanced technology that enhances performance and user experience. Its compact design allows for easy transportation, while its robust construction ensures durability in challenging environments.

Applications

This generator is ideal for numerous tasks, ranging from construction sites to outdoor events. It can power tools, lights, and other equipment, providing an essential resource for any demanding setting.

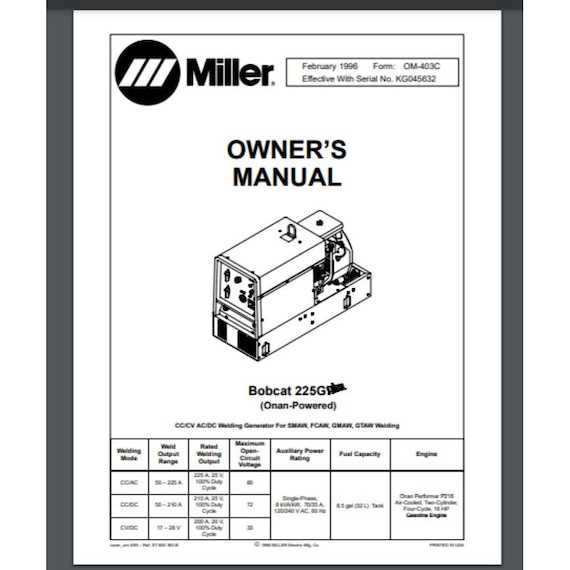

Key Features and Specifications

This section outlines the primary characteristics and technical details of the portable welding and generator unit, emphasizing its versatility and performance capabilities. Understanding these features can aid users in selecting the right equipment for their needs.

Performance Capabilities

The machine is designed to deliver consistent power, making it suitable for various applications in the field. Its efficient engine ensures reliability and durability, allowing for extended use in demanding environments.

Technical Specifications

| Specification | Details |

|---|---|

| Engine Type | Four-stroke, air-cooled |

| Output Power | Up to 10,500 watts |

| Welding Current | 20 – 225 amps |

| Fuel Capacity | 12 gallons |

| Weight | approximately 500 lbs |

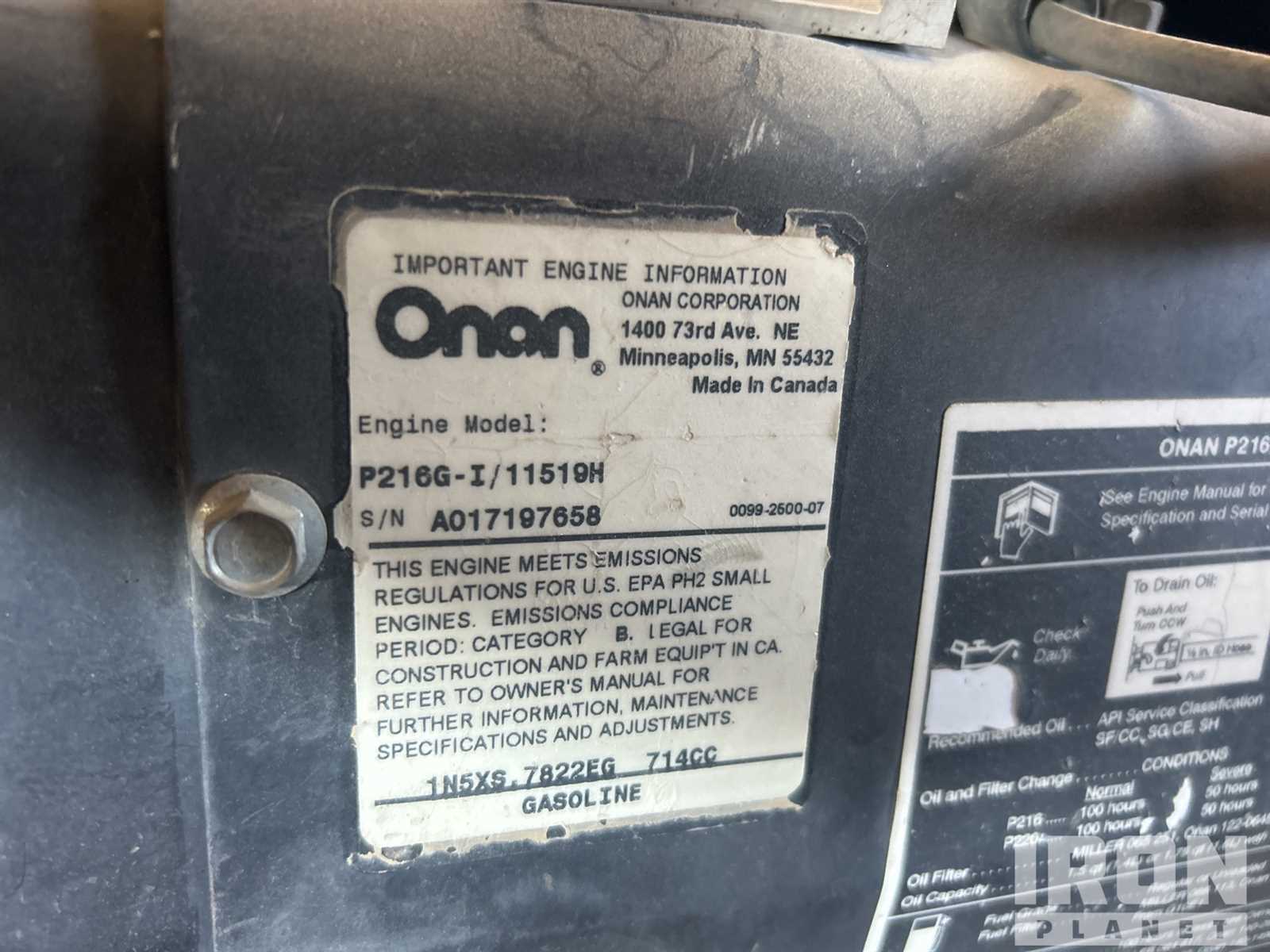

Maintenance and Care Guidelines

Regular upkeep and proper handling are essential for ensuring optimal performance and longevity of your equipment. Adhering to maintenance protocols not only enhances efficiency but also minimizes the risk of unexpected failures.

Routine Inspection

Conducting frequent checks allows for the early detection of potential issues. Look for signs of wear or damage in key components, and ensure that all parts are functioning as intended.

Cleaning Procedures

Keeping the machinery clean is vital for its efficient operation. Remove dirt and debris regularly to prevent buildup that could affect performance. Utilize appropriate cleaning agents for different surfaces.

| Task | Frequency |

|---|---|

| Inspect components | Monthly |

| Change filters | Every 100 hours |

| Lubricate moving parts | Every 50 hours |