Understanding how to keep your equipment running smoothly is key to ensuring long-lasting performance and efficiency. This guide provides valuable insights into the care, operation, and servicing of machinery designed for agricultural use. Whether you’re a seasoned operator or new to handling such tools, maintaining your equipment properly will maximize its utility and lifespan.

In this section, we’ll explore essential aspects of handling your equipment, focusing on day-to-day tasks that promote reliability. From routine inspections to advanced maintenance, the following information covers crucial steps to help you get the most out of your machine, ensuring that it remains a reliable part of your work for years to come.

Additionally, we’ll touch on troubleshooting common issues that might arise during use. By following the recommended practices outlined here, you can prevent unnecessary breakdowns, reduce repair costs, and ensure that your machine is always ready for the job ahead.

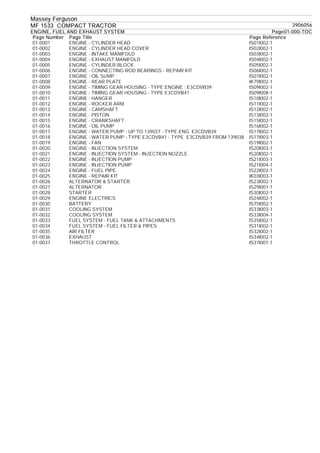

Maintenance Guidelines for Massey Ferguson 1533

Proper upkeep of agricultural equipment is essential to ensure reliable operation and extend its longevity. Regular inspections and service tasks help prevent unexpected issues and maintain the machine’s performance. By following essential care practices, operators can reduce the risk of costly repairs and downtime.

First, it is important to establish a routine for checking fluid levels, including engine oil, coolant, and hydraulic systems. Ensuring that all fluids are at the correct levels will help the equipment run smoothly and prevent damage caused by overheating or lack of lubrication.

Another key aspect is inspecting and cleaning the air filters regularly. A clogged or dirty air filter can reduce engine efficiency and lead to higher fuel consumption. By keeping the filters clean, you promote better airflow and more efficient fuel usage.

Operators should also examine the tires for proper inflation and any signs of wear or damage. Well-maintained tires improve traction and reduce fuel consumption, while damaged tires can lead to unsafe conditions and reduced productivity.

Lastly, keeping all moving parts well-lubricated is crucial to avoid premature wear and tear. Regular greasing of joints and bearings will enhance the machine’s functionality and extend its lifespan.

Understanding Basic Operations and Controls

To ensure smooth and efficient use of your equipment, it is essential to become familiar with the fundamental functions and operational features. By understanding how to handle key controls and mechanisms, users can maximize productivity while maintaining safety. This section will guide you through the core aspects of operating your machinery and adjusting settings for different tasks.

Main Dashboard and Indicators

The central control panel provides crucial information about the system’s performance and status. It typically includes a set of gauges and lights that indicate speed, fuel levels, and engine temperature. Familiarize yourself with these indicators to quickly assess your machine’s condition and respond to any issues.

Control Levers and Pedals

Operational levers and pedals are essential for maneuvering the machine and performing specific tasks. These controls may manage movement direction, lift attachments, and regulate speed. Ensure you know the purpose of each control to operate efficiently in various conditions.

| Control | Function | |||||

|---|---|---|---|---|---|---|

| Steering Wheel | Used to direct the machine’s movement | |||||

| Throttle | Regulates engine speed for better control | |||||

| Brake Pedal | Stops the machine safely |

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine Won’t Start | Dead Battery, Fuel Issues |