The importance of having a comprehensive resource for managing agricultural machinery cannot be overstated. This guide aims to provide valuable insights and practical information that every user should consider when operating their equipment. Understanding the functionality and maintenance of your machine ensures optimal performance and longevity.

Familiarizing yourself with operational procedures is crucial for effective use. This includes knowing the various features and capabilities of the tractor, as well as safety precautions to follow during operation. A solid understanding of these elements can significantly enhance efficiency and reduce the risk of accidents.

Moreover, regular maintenance is vital to prevent potential issues and ensure that the machinery runs smoothly. By following best practices outlined in this guide, users can make informed decisions regarding upkeep and troubleshooting, ultimately leading to a more productive and trouble-free experience.

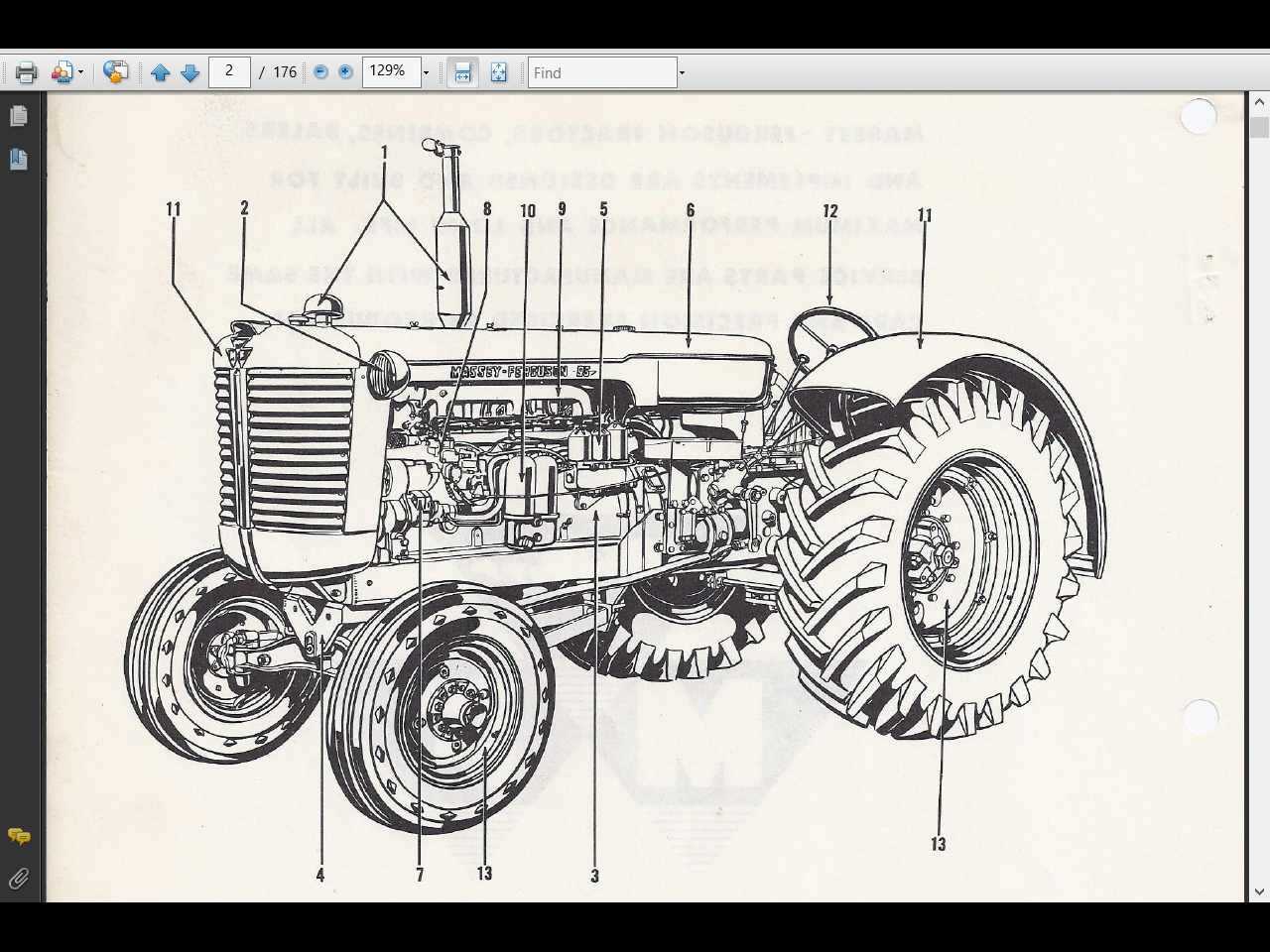

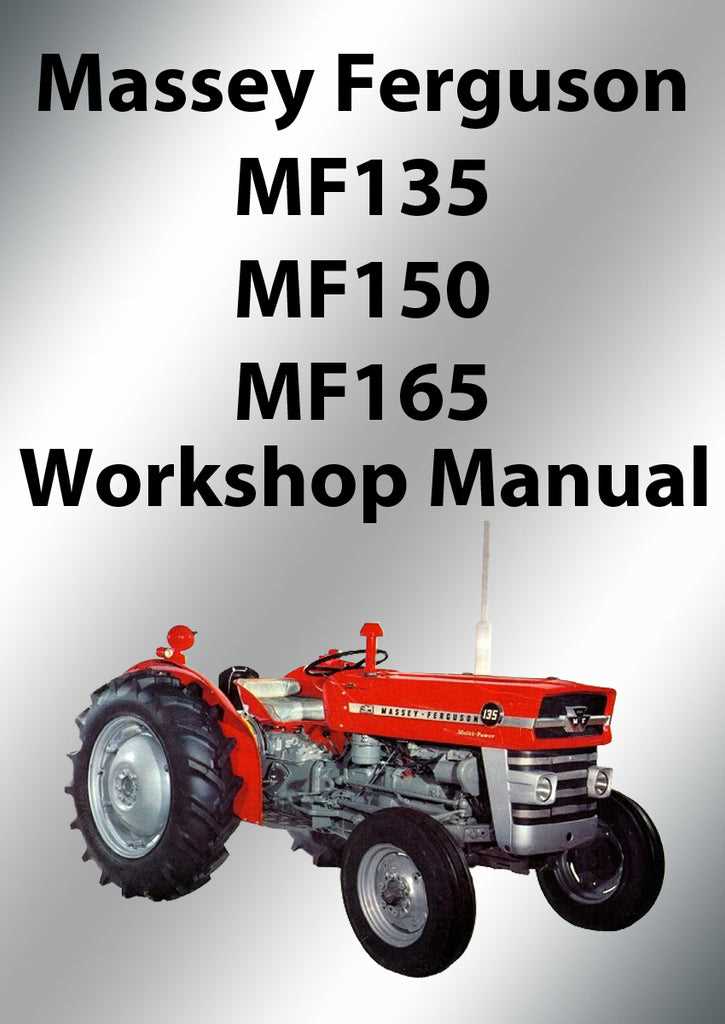

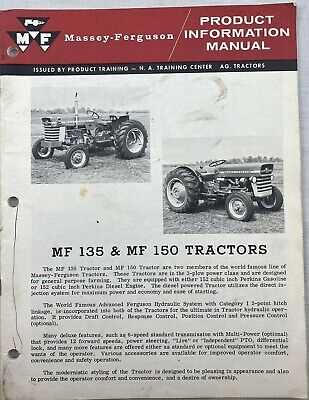

Essential Features of Massey Ferguson 135

This section highlights the key attributes of a renowned agricultural vehicle, known for its reliability and performance in various farming tasks. Understanding these features can enhance the user experience and optimize operational efficiency.

Power and Efficiency

- Robust engine providing ample horsepower for demanding tasks.

- Fuel-efficient design that minimizes operational costs.

- Responsive transmission system for smooth gear shifting.

User-Friendly Design

- Ergonomic controls that ensure comfort during extended use.

- Accessible maintenance points for simplified servicing.

- Versatile attachments enhancing functionality for diverse applications.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your machinery operates smoothly and efficiently. By following a consistent maintenance routine, you can enhance performance, extend the lifespan of components, and prevent unexpected breakdowns.

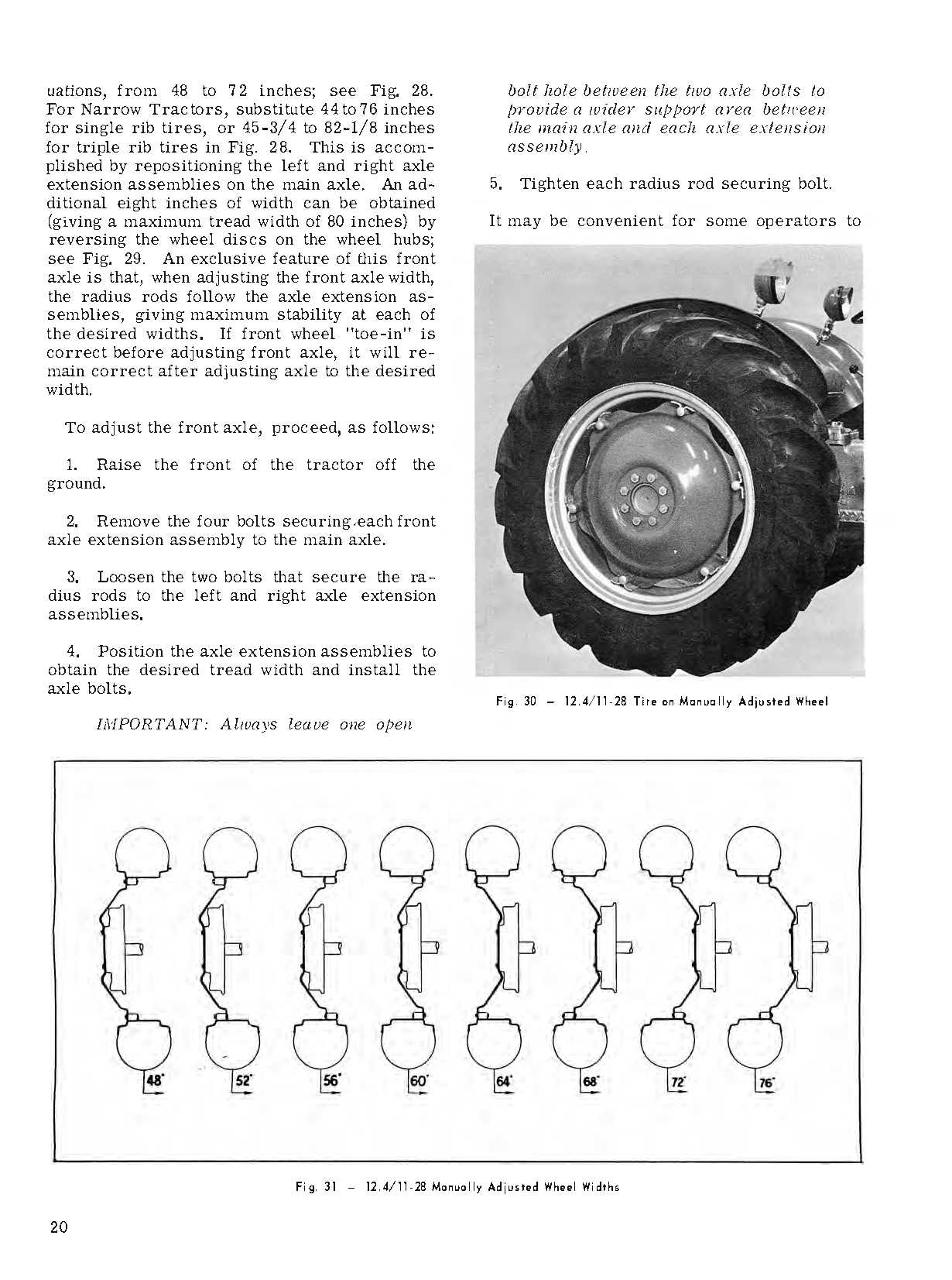

Routine Inspections

Conduct frequent checks on key systems to identify any signs of wear or potential issues. Pay special attention to fluid levels, filters, and belts, as these elements play a critical role in overall functionality.

Proper Lubrication

Ensure that all moving parts are adequately lubricated to minimize friction and reduce the risk of damage. Use the appropriate lubricants recommended by the manufacturer, and apply them at regular intervals to maintain optimal operation.

Common Issues and Troubleshooting Solutions

When operating agricultural machinery, encountering certain challenges is common. Understanding these issues and knowing how to address them can significantly enhance performance and reliability. This section provides insights into frequent problems and their effective solutions.

Engine Performance Problems

One of the most prevalent concerns involves engine performance. If the engine struggles to start or runs unevenly, it may indicate fuel delivery issues or air blockages. Checking the fuel filters and ensuring proper air intake can often resolve these complications.

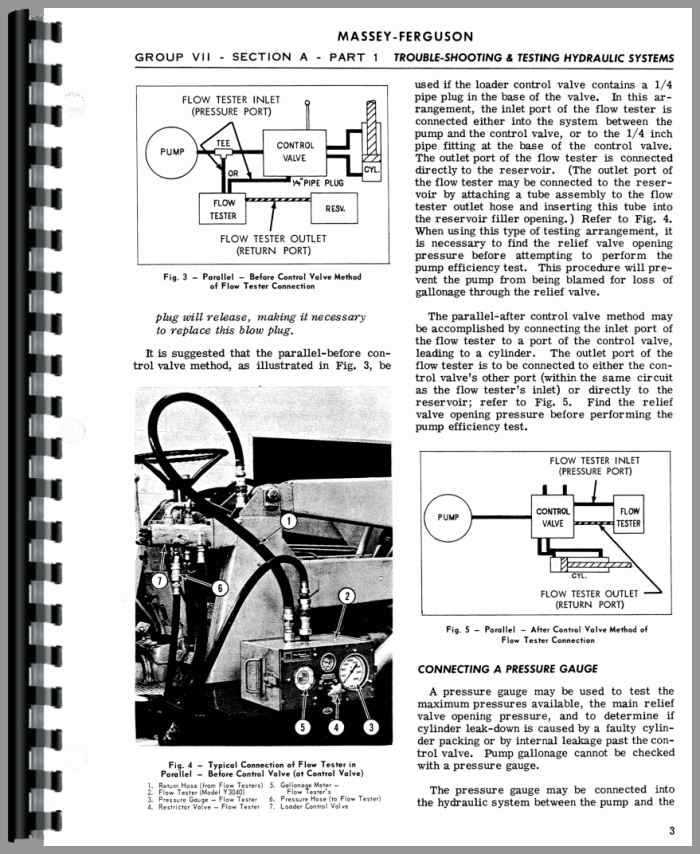

Hydraulic System Failures

Hydraulic system malfunctions can lead to decreased operational efficiency. If hydraulic components do not respond as expected, inspect the fluid levels and check for leaks in the hoses. Regular maintenance of the hydraulic system can prevent many issues from arising.