The following section serves as a comprehensive resource for understanding the functionalities and features of a specific welding machine. This guide aims to assist users in maximizing their experience with the equipment, ensuring safe and efficient operation.

Detailed explanations will be provided regarding various aspects, including setup, operation, and maintenance practices. Emphasis will be placed on user-friendly approaches to troubleshoot common issues and enhance overall performance.

By exploring the contents of this guide, users will gain valuable insights into optimizing the machine’s capabilities. The goal is to empower individuals to handle their equipment confidently and proficiently.

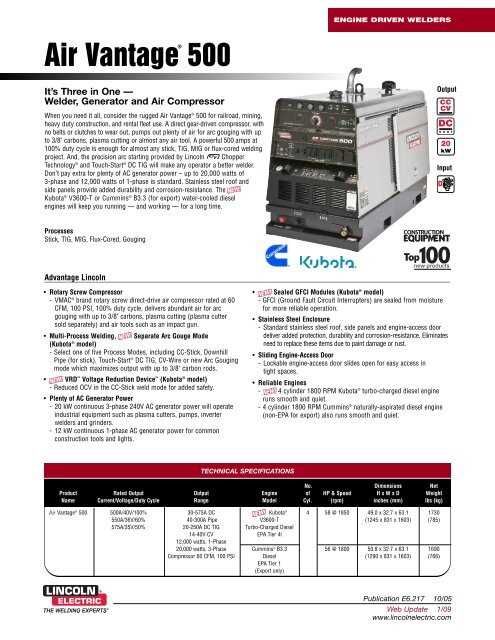

Overview of Lincoln Vantage 300 Features

This section provides a comprehensive insight into the functionalities and characteristics of the advanced welding equipment. Designed for both professionals and enthusiasts, this device offers a range of features that enhance performance and usability.

- Powerful Performance: The machine is engineered to deliver exceptional power output, suitable for various welding applications.

- Portability: Lightweight and compact design ensures easy transportation and setup, making it ideal for job sites.

- Versatile Welding Processes: Capable of supporting multiple welding techniques, including MIG, TIG, and stick welding.

- User-Friendly Interface: Intuitive controls allow for effortless adjustments, catering to both novices and seasoned operators.

- Durability: Built with robust materials to withstand harsh working environments, ensuring long-lasting use.

- Safety Features: Equipped with advanced safety mechanisms to protect users and enhance operational reliability.

These attributes collectively contribute to the efficiency and effectiveness of the equipment, making it a valuable tool in the welding industry.

Maintenance Guidelines for Optimal Performance

Regular upkeep is essential for ensuring the efficient functioning of your equipment. Following recommended practices can significantly enhance its longevity and performance. This section outlines key maintenance protocols to achieve optimal results.

To maintain peak efficiency, adhere to the following maintenance schedule:

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect and clean air filters | Every 30 hours of use | Replace if excessively dirty |

| Check fluid levels | Weekly | Top off as necessary |

| Examine electrical connections | Monthly | Look for corrosion and secure loose connections |

| Change oil and filters | Every 100 hours of operation | Use manufacturer-recommended oil |

| Inspect hoses and belts | Every 50 hours of use | Replace if signs of wear are present |

Implementing these guidelines will help ensure your equipment operates smoothly and efficiently, reducing the likelihood of unexpected issues.

Troubleshooting Common Operational Issues

This section addresses frequent challenges encountered during the use of welding equipment. Understanding typical problems and their solutions can enhance the performance and longevity of the device.

Identifying Problems

Recognizing issues promptly is crucial for effective resolution. Common symptoms include irregular performance, unexpected shutdowns, and inconsistent output. Keeping an eye on these indicators can facilitate timely interventions.

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Inconsistent Arc | Improper settings or worn-out consumables | Check and adjust settings; replace consumables if necessary. |

| Overheating | Blocked air vents or inadequate cooling | Ensure vents are clear; allow the device to cool down before use. |

| Unexpected Shutdown | Electrical issues or overload | Inspect power supply and circuits; reset overload protection if triggered. |

| Erratic Power Supply | Faulty connections or damaged cables | Inspect connections and cables; replace any damaged components. |