In the realm of agricultural and landscaping tools, having access to a comprehensive resource can significantly enhance the user experience. Such a guide offers valuable insights into the effective operation, maintenance, and troubleshooting of your machinery, ensuring optimal performance and longevity.

This informative section is designed to provide essential information tailored for users of a specific model, emphasizing practical tips and procedures. By understanding the features and recommended practices, operators can maximize efficiency and avoid common pitfalls associated with equipment use.

Additionally, familiarity with the intricacies of your machinery will empower users to tackle challenges confidently. Whether it’s routine maintenance or addressing unexpected issues, having a reliable reference is crucial for achieving the best outcomes in your work.

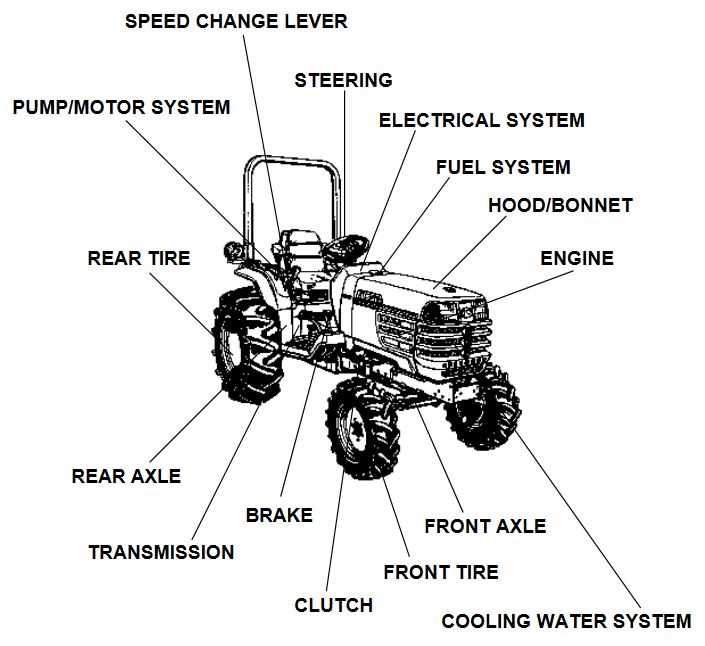

Essential Features of Kubota ZD1511

This section highlights the key characteristics that make this model stand out in its category. Designed for efficiency and user-friendliness, it incorporates advanced technology to enhance performance and ease of operation.

Powerful Engine

The heart of this machine lies in its robust engine, which offers remarkable torque and reliability. Key aspects include:

- High-performance engine for enhanced productivity

- Efficient fuel consumption for longer operational hours

- Reduced emissions for environmentally conscious usage

User-Friendly Design

Ergonomically designed, this model ensures comfort and convenience for operators. Notable features encompass:

- Intuitive controls for easy navigation

- Spacious operator platform for improved comfort

- Exceptional visibility for better maneuverability

Maintenance Guidelines for Optimal Performance

Regular upkeep is essential to ensure the longevity and efficiency of your machinery. Implementing a systematic maintenance routine not only enhances performance but also prevents potential issues that may arise from neglect. By adhering to specific guidelines, you can maximize the functionality and reliability of your equipment.

Routine Inspections

Conducting frequent assessments of key components, such as the engine and filters, is crucial. Look for signs of wear or damage and replace parts as necessary. Keeping the fuel system clean and ensuring fluid levels are adequate can significantly improve operational efficiency.

Cleaning and Lubrication

Regularly cleaning the exterior and internal parts helps to prevent dirt and debris accumulation, which can hinder performance. Additionally, proper lubrication of moving parts minimizes friction and reduces wear, ensuring smoother operation. Following the manufacturer’s specifications for lubricant types and intervals is vital for optimal results.

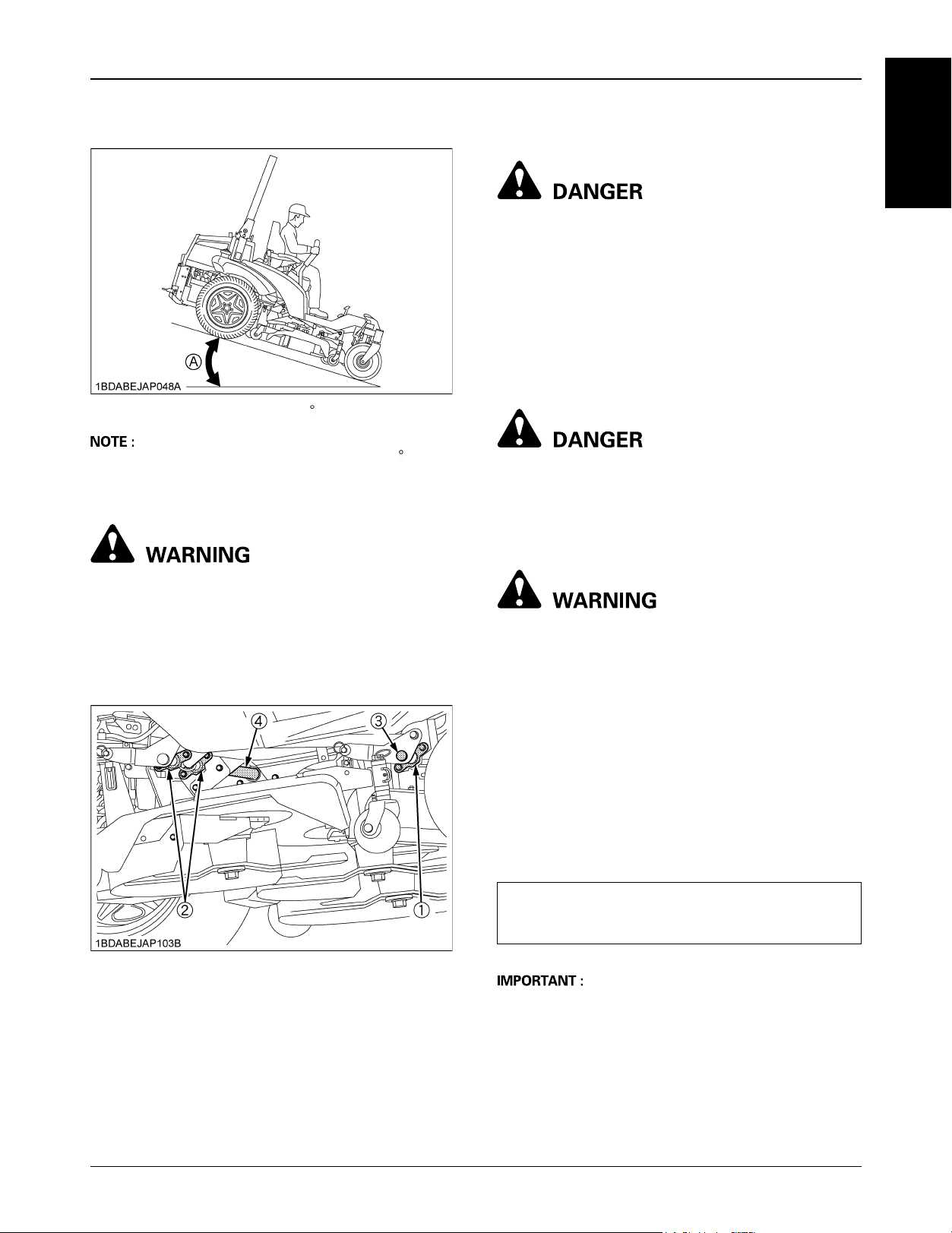

Safety Tips for Safe Operation

Ensuring safe usage of machinery is crucial for preventing accidents and injuries. Adhering to safety guidelines promotes a secure environment for both the operator and bystanders. Familiarizing oneself with essential precautions can significantly reduce risks during operation.

Pre-Operation Checks

Before commencing work, it is vital to conduct thorough inspections. Check fluid levels, brakes, and safety features. Ensure that all components are functioning correctly. Wear appropriate personal protective equipment to enhance safety during operation.

Operating Procedures

During use, maintain a clear workspace and avoid distractions. Always follow the manufacturer’s instructions for safe handling. Keep hands and feet away from moving parts and remain alert to your surroundings to prevent accidents. Regularly review safety practices to stay informed.