Understanding the operation and maintenance of heavy machinery is crucial for maximizing performance and ensuring longevity. This section offers vital insights into the key aspects that every user should be familiar with. By following the recommended practices, you can enhance both safety and efficiency in your daily tasks.

Maintenance is a fundamental component that ensures the machinery operates smoothly over time. Regular checks and timely interventions can prevent major issues, saving both time and resources. Additionally, being aware of the recommended procedures for care can significantly extend the life of your equipment.

Furthermore, familiarizing yourself with the various features and functionalities of your machine allows for optimal utilization. Knowledge of specific operations not only improves productivity but also empowers users to troubleshoot common challenges effectively. Engaging with this information is essential for anyone looking to achieve the best results in their work environment.

Operation Guidelines

This section provides essential insights into effectively managing your equipment. Understanding the operational protocols ensures safety, efficiency, and longevity of the machinery.

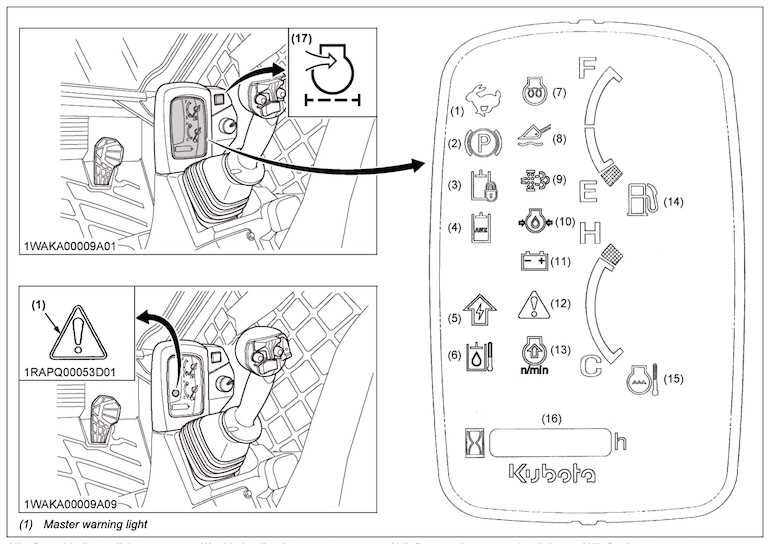

- Pre-Operation Checks:

- Inspect all fluid levels before use.

- Examine the condition of the tracks and tires.

- Ensure safety features are functioning properly.

- Starting Procedures:

- Enter the cabin and adjust the seat for comfort.

- Engage the parking brake.

- Turn the ignition key to start the engine.

- Operational Techniques:

- Utilize smooth movements to maintain stability.

- Monitor load capacity to prevent overloading.

- Adhere to speed limits for safety.

- Post-Operation Procedures:

- Park the machinery on level ground.

- Turn off the engine and engage the parking brake.

- Conduct a brief inspection to identify any issues.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the efficiency and longevity of your equipment. By following a consistent maintenance routine, owners can prevent unexpected breakdowns and enhance overall functionality. This section outlines key strategies to achieve peak performance.

Routine Inspections

- Check fluid levels regularly, including oil and coolant.

- Inspect filters and replace them as needed to maintain airflow and performance.

- Examine hoses and belts for signs of wear or damage.

Cleaning and Lubrication

- Clean the exterior to prevent dirt buildup that can affect operation.

- Lubricate moving parts to reduce friction and wear.

- Ensure all joints and pivot points are adequately serviced.

By implementing these practices, operators can ensure their machinery remains in optimal condition, ultimately leading to improved performance and efficiency.

Common Issues and Troubleshooting Solutions

When operating heavy machinery, it’s essential to be aware of potential challenges that may arise. Identifying these common problems early can help ensure smooth performance and extend the lifespan of the equipment. Below are several frequent issues owners encounter, along with effective troubleshooting strategies.

Engine Performance Problems

One of the most common concerns relates to engine performance. Symptoms may include reduced power, excessive noise, or difficulty starting. Regular maintenance checks are crucial for addressing these issues promptly.

Hydraulic System Failures

The hydraulic system is vital for various functions. Signs of malfunction can include slow operation or unexpected drops in pressure. Ensuring that hydraulic fluid levels are adequate and checking for leaks can help mitigate these problems.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| Engine Won’t Start | Clicking sound, no ignition | Check battery connections and fuel levels |

| Loss of Power | Sluggish performance | Inspect air filter and fuel system |

| Hydraulic Fluid Leak | Puddles under equipment | Examine hoses and fittings for damage |

| Overheating | Temperature gauge rising | Check coolant levels and radiator |