Maintaining your lawn care equipment is essential for optimal performance and longevity. This section provides comprehensive insights into the operation and upkeep of your tractor, ensuring you achieve the best results in your gardening tasks.

Understanding the key features and functionalities will empower you to utilize the machine effectively. By familiarizing yourself with essential maintenance practices, you can prevent potential issues and enhance the overall efficiency of your equipment.

Whether you’re a seasoned operator or a newcomer, this guide aims to equip you with the necessary knowledge to ensure your machine operates smoothly and reliably. Embrace the tips and recommendations provided to keep your tractor in excellent condition and enjoy a thriving landscape.

Essential Maintenance for John Deere X300

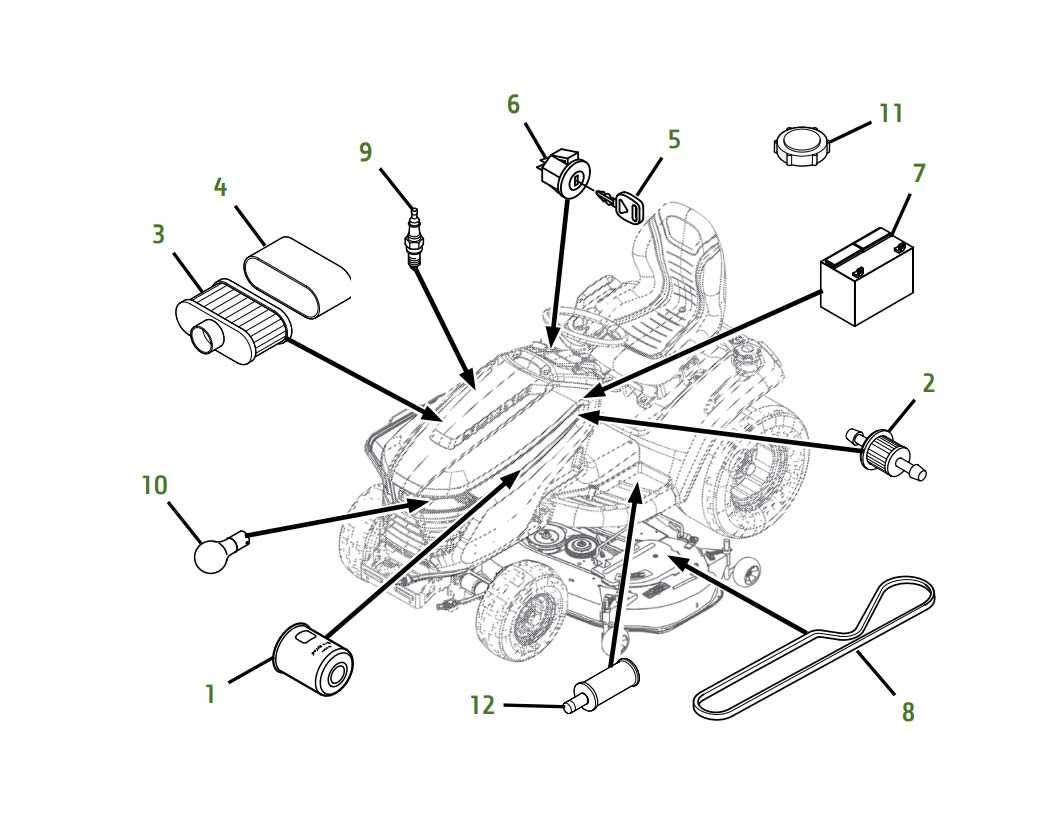

Regular upkeep is vital for ensuring optimal performance and longevity of your machinery. By adhering to a consistent maintenance schedule, you can prevent potential issues and enhance efficiency, resulting in a smoother operation and reduced repair costs.

Routine Checks

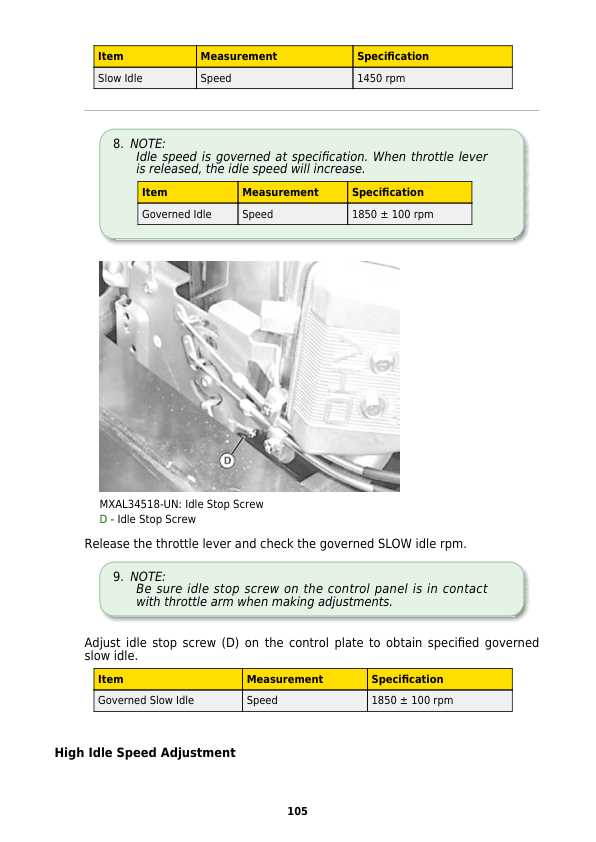

Conducting frequent inspections is crucial. This includes examining the fuel, oil, and air filters, as well as checking tire pressure and overall condition. Keeping these elements in check can significantly improve functionality and safety.

Seasonal Maintenance

Seasonal care should also be a priority. Preparing the equipment for winter or summer months involves specific tasks like winterizing fluids or checking battery health. Such proactive measures can mitigate the risk of breakdowns when they are needed most.

Operating Instructions and Best Practices

This section aims to provide essential guidance for effectively utilizing your equipment. Understanding the fundamental operational techniques can significantly enhance performance and longevity.

Preparation: Before starting, ensure that all components are in optimal condition. Regular checks on fluids, tires, and blades will prevent potential issues and improve functionality.

Starting Procedure: Follow a systematic approach when powering up. Engage the safety features and verify that all controls are set to neutral to avoid accidental movement.

Best Practices: Familiarize yourself with the various settings and their applications. Utilizing the appropriate speed and cutting height for different terrains not only enhances results but also reduces wear on the machine.

Lastly, always consult your specific guidelines for maintenance intervals. Routine upkeep is crucial for ensuring reliable operation and minimizing downtime.

Troubleshooting Common Issues Effectively

Addressing frequent challenges can greatly enhance the user experience and prolong the lifespan of your equipment. By systematically identifying and resolving typical problems, you can ensure optimal performance and avoid unnecessary repairs.

Identifying the Symptoms

Start by observing any unusual behavior. Look for signs like strange noises, unexpected shutdowns, or irregular operation. Documenting these symptoms helps in diagnosing the underlying issues more accurately.

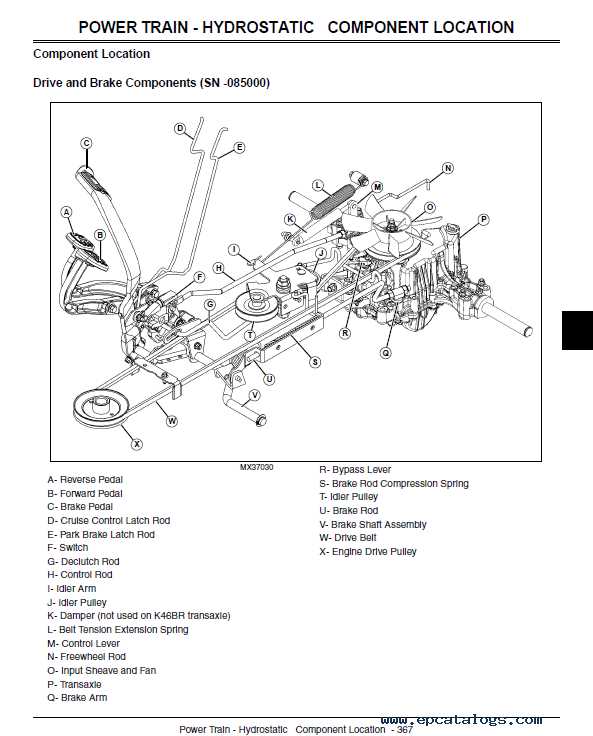

Step-by-Step Solutions

Once symptoms are noted, consult the troubleshooting guide for potential fixes. Begin with basic checks, such as verifying fluid levels and connections. If problems persist, deeper analysis may be required, focusing on specific components to pinpoint failures.