The effective operation and maintenance of agricultural machinery are crucial for maximizing performance and longevity. Understanding the intricacies of your equipment can significantly enhance productivity and minimize downtime. This section aims to provide essential insights and practical guidance tailored for individuals seeking to optimize their machinery experience.

In this guide, readers will discover valuable tips on routine care, troubleshooting common issues, and maximizing the functionality of their machinery. Emphasizing the importance of proper knowledge, it will serve as a reliable resource for both seasoned operators and newcomers alike. With the right information at your fingertips, you can ensure that your equipment runs smoothly and efficiently.

Whether you are looking to enhance your operational skills or seeking advice on maintenance practices, this guide will empower you with the confidence and expertise needed to handle your machinery effectively. Embrace the journey of becoming a more informed and capable operator.

Understanding the John Deere 955 Manual

Gaining familiarity with the documentation that accompanies your agricultural machinery is crucial for optimal operation and maintenance. This resource serves as a comprehensive guide, providing essential information to ensure the effective use of your equipment. By understanding this reference material, users can enhance their experience and prolong the lifespan of their investment.

Key Components of the Documentation

- Operating Instructions: Detailed guidelines on how to efficiently operate the machinery.

- Maintenance Schedules: Recommended timelines for regular upkeep and servicing tasks.

- Troubleshooting Tips: Common issues and their solutions to minimize downtime.

Importance of Following Guidelines

- Ensures safety while operating the machinery.

- Promotes efficient performance and fuel economy.

- Reduces the risk of costly repairs and extends equipment longevity.

By utilizing this documentation effectively, users can achieve a higher level of productivity and satisfaction with their equipment.

Essential Maintenance Tips for Owners

Proper upkeep of your equipment is crucial for ensuring its longevity and optimal performance. Regular maintenance not only helps in identifying potential issues early on but also enhances efficiency, ultimately saving you time and money in the long run.

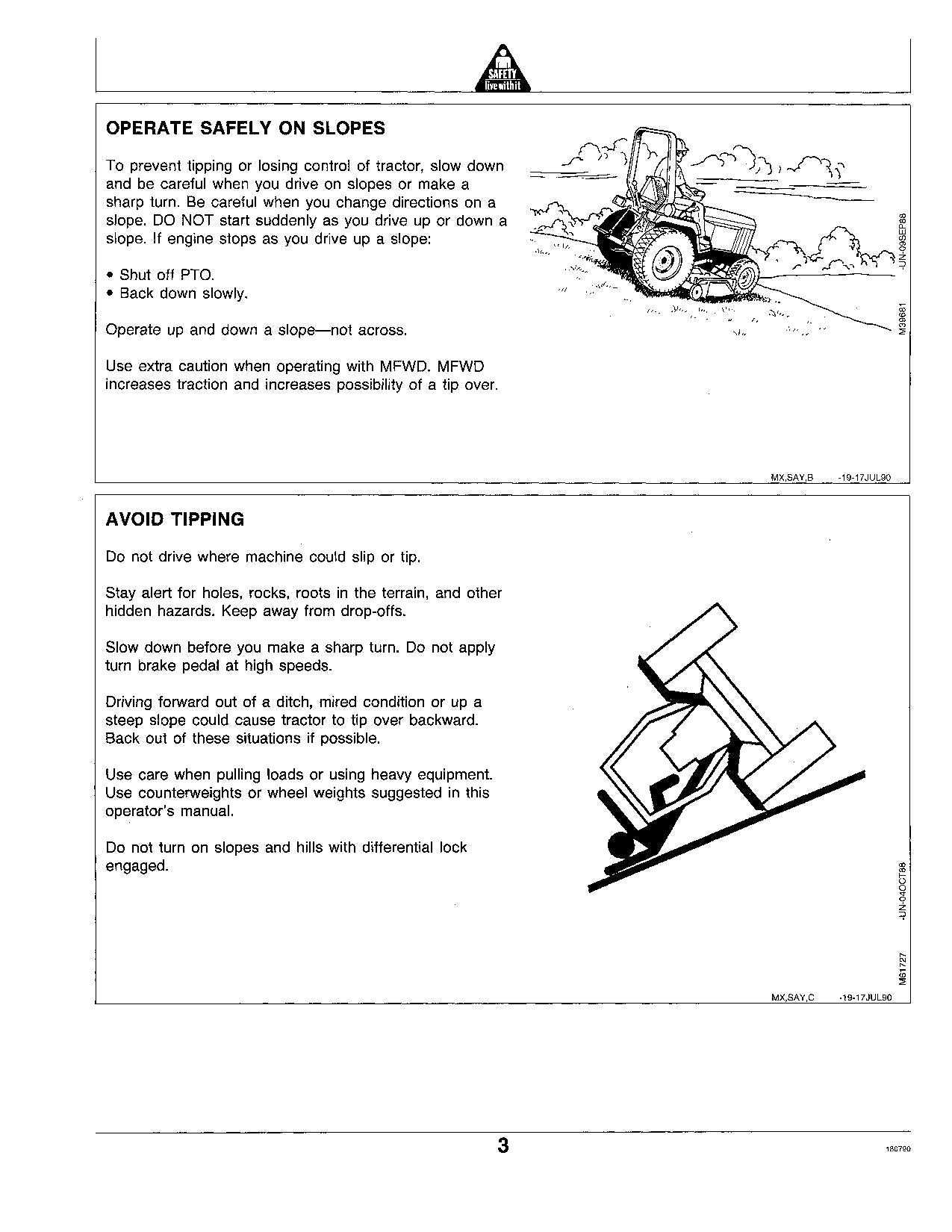

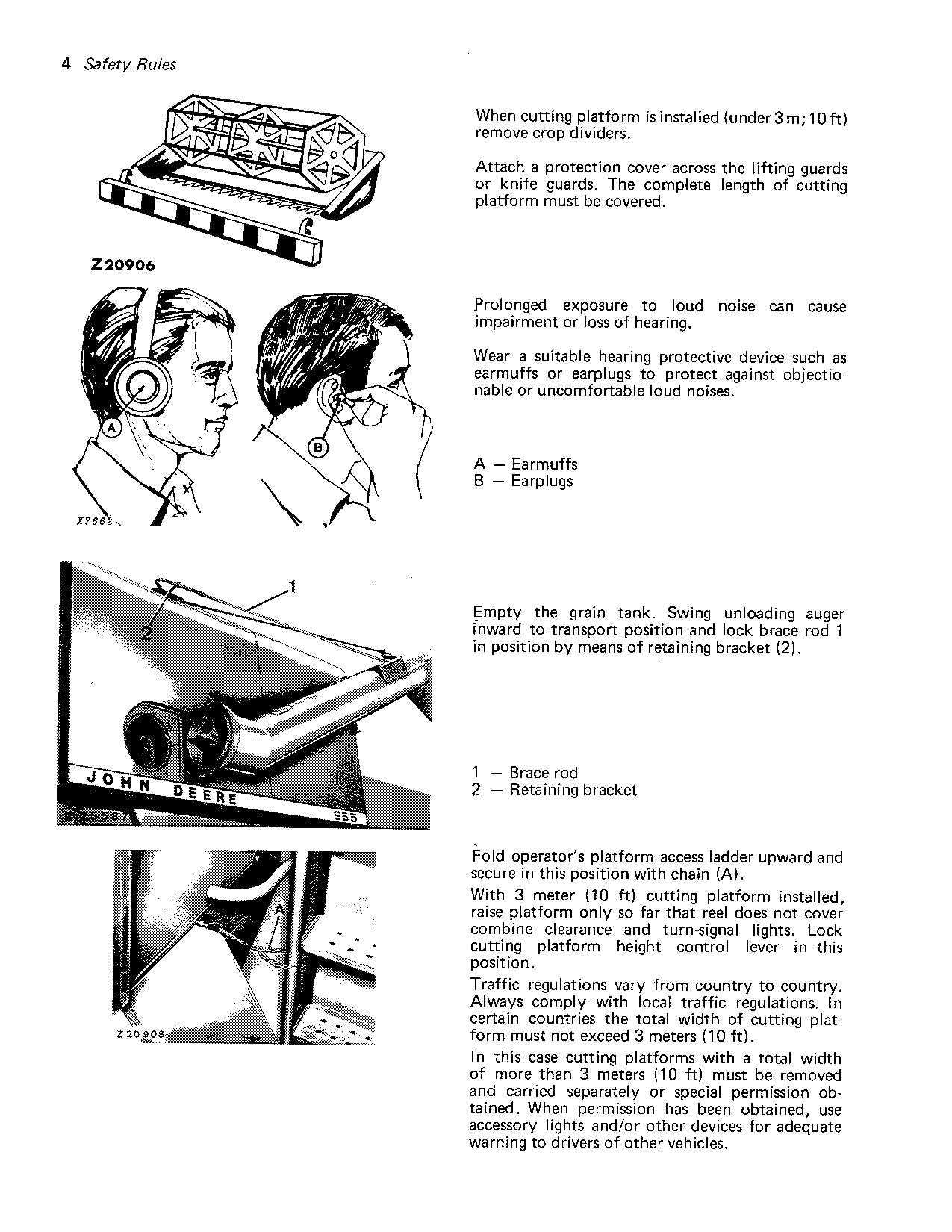

1. Regular Inspections: Conduct frequent checks on all vital components, including the engine, transmission, and hydraulic systems. Look for signs of wear or damage, and address any issues immediately to prevent more significant problems.

2. Fluid Levels: Keep an eye on essential fluids such as oil, coolant, and hydraulic fluid. Regularly topping off and replacing these fluids as recommended will help maintain engine health and overall functionality.

3. Cleaning: Regularly clean the equipment to remove dirt, debris, and buildup that can hinder performance. Pay particular attention to air filters, radiators, and other cooling components to ensure they remain clear and efficient.

4. Tire Maintenance: Monitor tire pressure and tread depth regularly. Proper inflation is essential for traction and fuel efficiency, while worn tires can lead to unsafe operating conditions.

5. Seasonal Preparation: Before changing seasons, perform a thorough inspection and servicing of your equipment. This preparation will help ensure reliability, especially during peak usage times.

6. Follow Guidelines: Adhere to the recommended service intervals provided by the manufacturer. Keeping up with these guidelines is vital for maintaining warranty coverage and prolonging the life of your machine.

Implementing these maintenance tips will not only ensure your machinery operates smoothly but also enhance its lifespan and reliability in the field.

Common Troubleshooting Techniques Explained

Troubleshooting is an essential skill that allows individuals to identify and resolve issues effectively. By employing systematic approaches, users can minimize downtime and enhance the performance of their machinery. This section outlines several practical methods for diagnosing common problems.

1. Visual Inspection: Start with a thorough visual examination of the equipment. Look for any obvious signs of wear, damage, or disconnections. This technique can often reveal issues that are easy to fix and can prevent further complications.

2. Check the Fluid Levels: Ensuring that oil, coolant, and other vital fluids are at appropriate levels is crucial. Low fluid levels can lead to overheating or other operational failures. Regularly monitoring these can help maintain optimal performance.

3. Listen for Unusual Sounds: Paying attention to the noises produced by the machinery can provide important clues about underlying problems. Strange sounds may indicate mechanical issues that require immediate attention.

4. Use Diagnostic Tools: Many modern devices come equipped with onboard diagnostics. Utilizing these tools can help pinpoint issues quickly and accurately. Refer to the device’s specifications for guidance on interpreting diagnostic codes.

5. Consult the Documentation: Accessing the technical documentation can offer valuable insights into common problems and their solutions. It serves as a reference point for troubleshooting steps and provides detailed specifications.

6. Seek Professional Help: If the problem persists despite trying various methods, it may be time to consult a qualified technician. Their expertise can save time and prevent potential damage by ensuring the issue is resolved correctly.

Implementing these techniques can empower users to troubleshoot effectively, leading to improved efficiency and longevity of their equipment.