This section aims to provide essential insights and guidance for individuals utilizing robust cutting equipment designed for efficiency and precision. Understanding the functionality and maintenance of these tools is crucial for maximizing their potential in various tasks.

Within these guidelines, users will discover vital information about operational techniques, safety precautions, and best practices to enhance performance. By adhering to these principles, operators can ensure a longer lifespan for their equipment and achieve optimal results in their cutting endeavors.

Moreover, the significance of routine upkeep and proper handling cannot be overstated. Emphasizing regular checks and attentive care fosters reliability and effectiveness, allowing users to confidently tackle a range of outdoor projects.

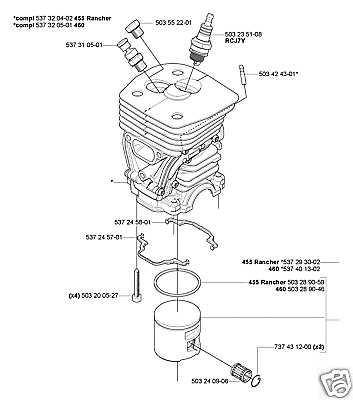

Essential Features of the Husqvarna 450 Rancher

This section outlines the key attributes that make this cutting tool highly effective and user-friendly. Designed for both professional and recreational users, it incorporates a range of features that enhance performance and usability.

- Powerful Engine: The machine is equipped with a robust motor that delivers excellent cutting power, allowing for efficient handling of various materials.

- Lightweight Design: Its construction minimizes weight, making it easier to maneuver during extended use.

- Vibration Dampening System: This feature significantly reduces operator fatigue, ensuring comfort during prolonged tasks.

- Quick-Release Air Filter: Maintenance is simplified with an easily accessible air filtration system, ensuring optimal performance.

- Automatic Oiling System: This system maintains the chain lubrication, enhancing the longevity and efficiency of the tool.

These features contribute to a well-rounded cutting tool that is suitable for various applications, from tree felling to firewood preparation.

Safety Guidelines for Chain Saw Use

Proper handling and precautions are essential when operating cutting equipment. Adhering to safety measures can significantly reduce the risk of accidents and ensure a more efficient work process.

Pre-Operation Safety Checks

- Inspect the equipment for any signs of damage or wear.

- Ensure that safety features are functioning correctly.

- Confirm that the cutting tool is sharp and properly attached.

Personal Protective Equipment

- Wear a hard hat to protect against falling debris.

- Use eye protection to shield against flying particles.

- Wear gloves for a secure grip and hand protection.

- Utilize sturdy boots with slip-resistant soles.

Maintenance Tips for Optimal Performance

Proper upkeep is essential for ensuring that your equipment operates at its best. Regular maintenance not only enhances efficiency but also extends the lifespan of the device. By following a few key practices, you can achieve consistent performance and reliability in your tool.

Regular Cleaning

Cleaning the tool after each use is vital. Remove any debris, sawdust, or residue that may accumulate on the exterior and in the air intake. This practice prevents overheating and allows for better airflow, which is crucial for optimal functioning.

Inspecting Components

Frequent inspections of various parts, such as the cutting mechanism and fuel system, are necessary to identify wear and tear. Look for signs of damage or loosening that may affect performance. Addressing minor issues promptly can prevent larger problems down the line.