This comprehensive resource aims to equip users with the knowledge necessary to operate their cleaning devices effectively and safely. By following the outlined guidelines, individuals can maximize the performance of their equipment, ensuring optimal results with minimal effort.

Understanding the various components and functionalities of your cleaning machine is crucial for maintaining its efficiency. This section will delve into key features, operational techniques, and essential maintenance practices, empowering users to tackle a range of cleaning tasks with confidence.

Additionally, familiarizing yourself with safety precautions and troubleshooting tips can greatly enhance your experience. Whether you are a novice or a seasoned user, this guide serves as a valuable companion, paving the way for a successful and satisfying cleaning experience.

Understanding Your Excell Pressure Washer

Familiarizing yourself with your cleaning device can enhance your experience and ensure optimal performance. This section aims to provide essential insights into the functionality, components, and maintenance of your machine, enabling you to make the most of its capabilities.

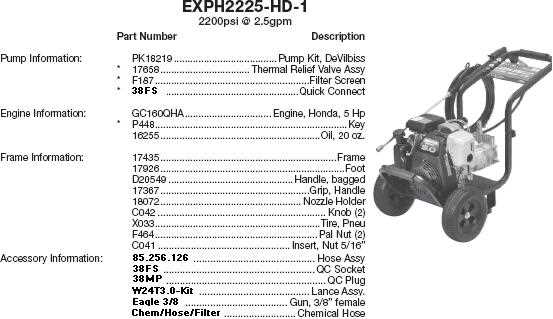

Device Components: Every cleaning apparatus consists of several key elements that work together to deliver effective results. Understanding the roles of the motor, pump, and nozzles will help you appreciate how each part contributes to the overall efficiency of the unit.

Operating Guidelines: Utilizing your equipment effectively requires knowledge of the various settings and modes available. By learning how to adjust pressure levels and select the appropriate nozzle for different tasks, you can achieve optimal cleaning results tailored to your specific needs.

Maintenance Tips: Regular upkeep is crucial for prolonging the lifespan of your device. Familiarize yourself with the necessary care routines, such as checking for leaks, cleaning filters, and ensuring the motor is functioning properly. Taking these proactive measures will help you avoid potential issues and maintain peak performance.

Safety Precautions: Engaging with your cleaning equipment involves certain risks. It is important to adhere to safety protocols, such as wearing protective gear and ensuring that the area is clear of obstacles. Understanding these precautions will promote a safe working environment and enhance your overall experience.

By gaining a deeper understanding of your cleaning device, you can improve its performance and efficiency, leading to a more satisfying experience with every use.

Essential Maintenance Tips for Longevity

Proper upkeep is crucial for extending the lifespan of your equipment and ensuring optimal performance. By implementing a few key practices, you can prevent premature wear and enhance the functionality of your device. Regular maintenance not only safeguards your investment but also improves efficiency and reliability during operation.

1. Regular Cleaning: After each use, it is vital to remove any dirt or debris from the exterior. A clean surface minimizes the risk of corrosion and other forms of damage. Additionally, ensure that any filters or nozzles are free of obstructions to maintain smooth operation.

2. Inspect Components: Frequently check all parts for signs of wear or damage. Pay special attention to hoses, connectors, and seals. Addressing minor issues promptly can prevent them from escalating into significant problems that require costly repairs.

3. Fluid Checks: Regularly inspect and replace fluids as necessary. Keeping the fluid levels at optimal standards ensures that all components operate smoothly. Using the correct types of fluids as specified in the guidelines is also essential for effective performance.

4. Seasonal Storage: If the equipment is not in use for extended periods, store it in a dry, protected location. Before storing, ensure it is completely drained of any remaining fluids. This practice prevents the buildup of moisture and potential damage during off-seasons.

5. Follow Manufacturer Guidelines: Always refer to the specific instructions provided by the manufacturer regarding maintenance practices. Adhering to these recommendations will help you understand the unique needs of your device and maintain its efficiency over time.

Common Troubleshooting Techniques Explained

In the realm of equipment maintenance, understanding basic diagnostic strategies can greatly enhance your experience and efficiency. This section outlines fundamental approaches to identifying and resolving issues that may arise during operation. By familiarizing yourself with these methods, you can ensure smoother functionality and prolong the lifespan of your device.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Device won’t start | Power source issues, faulty connections, or damaged components | Check power supply, inspect all connections, and replace damaged parts |

| Inconsistent performance | Clogged nozzles, low fluid levels, or air in the system | Clean the nozzles, refill fluids, and bleed the system to remove air |

| Unusual noises | Loose parts, motor wear, or debris in moving components | Tighten all connections, inspect the motor, and clear any obstructions |

| Leaks | Worn seals, loose fittings, or cracks in the housing | Replace seals, tighten fittings, and repair or replace damaged housing |