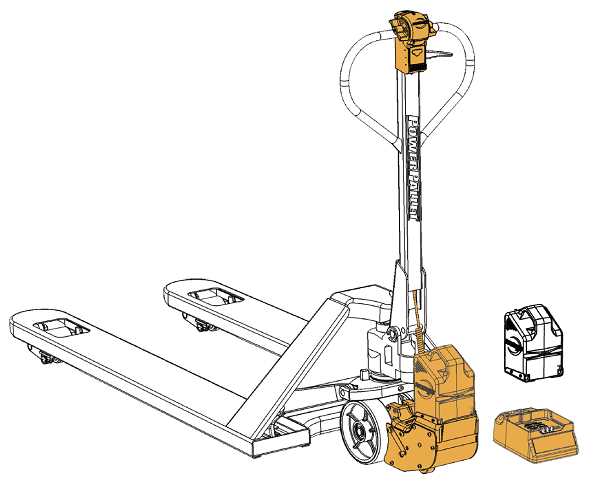

In the world of logistics and warehousing, having the right tools can significantly enhance productivity and safety. This section delves into the essential aspects of operating a specific type of lifting equipment, designed to facilitate the movement of heavy loads with ease and precision. Understanding its features and functionality is vital for both new users and seasoned operators.

Proper utilization and maintenance of this equipment not only improve workflow but also ensure a safe working environment. Familiarity with operational guidelines helps in maximizing efficiency, thereby reducing the likelihood of accidents. Whether for daily tasks or specialized applications, knowing how to handle this equipment is crucial for achieving optimal results.

As we explore the critical points of operating this machinery, we will highlight important safety practices, troubleshooting tips, and maintenance routines. By adhering to these recommendations, users can prolong the lifespan of their equipment and enhance overall performance. This guide serves as a valuable resource for anyone looking to improve their understanding and expertise in handling this vital tool.

This section outlines the fundamental characteristics and technical details of the equipment, highlighting its design and operational efficiency. Understanding these aspects can greatly enhance the user experience and ensure optimal performance in various settings.

Key Characteristics

The following table summarizes the primary features, providing a clear overview of the model’s capabilities:

| Feature | Description |

|---|---|

| Load Capacity | Designed to handle significant weight, ensuring durability and strength. |

| Lift Height | Allows for versatile handling of materials at different elevations. |

| Fork Width | Optimized for compatibility with various pallet sizes, facilitating ease of use. |

| Weight | Lightweight construction for enhanced maneuverability and transport. |

| Material | Crafted from robust materials to withstand daily wear and tear. |

Technical Specifications

In addition to the essential features, the following technical specifications are critical for effective operation:

| Specification | Details |

|---|---|

| Overall Dimensions | Compact design for easy storage and handling. |

| Wheel Type | Equipped with high-quality wheels for smooth movement on various surfaces. |

| Hydraulic System | Reliable hydraulic mechanism for efficient lifting and lowering. |

| Handle Type | Ergonomically designed for comfort and reduced operator fatigue. |

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the durability and performance of your equipment. Implementing effective maintenance practices not only extends the lifespan of your machinery but also enhances its operational efficiency. This section outlines key strategies for maintaining your device in optimal condition.

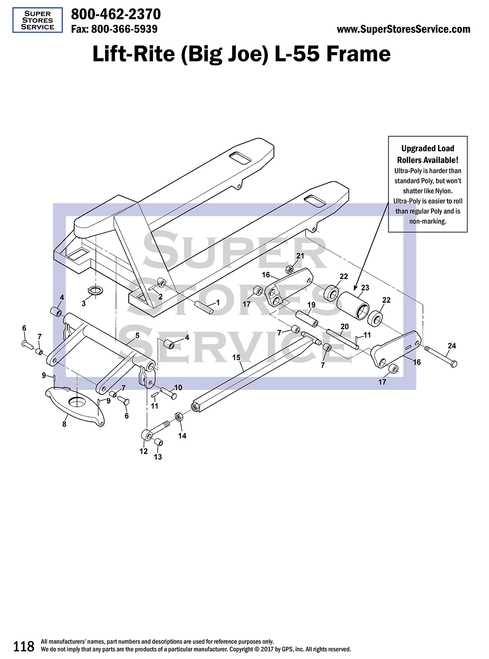

Routine Inspections

Conduct frequent examinations to identify any wear or potential issues before they escalate. Focus on key components, including wheels, handles, and lifting mechanisms. Addressing minor repairs promptly can prevent more significant problems later.

Proper Cleaning Techniques

Keep the equipment free from debris and contaminants that can lead to corrosion or malfunction. Utilize a soft cloth and appropriate cleaning solutions to maintain surfaces. Regularly inspect and clean moving parts to ensure smooth operation and reduce friction.

Safety Guidelines for Operation

Ensuring safe usage of material handling equipment is paramount to maintaining a secure workplace. Proper procedures and precautions should always be followed to minimize risks and enhance operational efficiency. Adhering to these guidelines can prevent accidents and promote a culture of safety.

Pre-Operational Checks

Before initiating the operation, it is essential to conduct thorough inspections. Regular checks help identify any potential hazards or maintenance needs that could compromise safety. Below are key aspects to consider during pre-operational checks:

| Inspection Area | Checkpoints |

|---|---|

| Wheels and Rollers | Ensure they are free from debris and functioning smoothly. |

| Handle | Verify that it is secure and operates properly. |

| Forks | Inspect for cracks or damages, ensuring they are properly aligned. |

| Hydraulic System | Check for leaks and proper fluid levels. |

Operational Procedures

When operating the equipment, following established protocols is vital. This includes maintaining a clear line of sight, avoiding overloading, and ensuring the area is free from obstructions. Additionally, operators should always remain aware of their surroundings and communicate effectively with team members to ensure a safe working environment.