Every skilled artisan understands the importance of having comprehensive guidance when it comes to operating their essential equipment. This section provides invaluable insights and detailed information to help you navigate the functionalities and maintenance of your powerful cutting device. Whether you are a novice or a seasoned expert, familiarizing yourself with the specifics will enhance your crafting experience.

Proper usage and maintenance of your instrument not only ensures optimal performance but also prolongs its lifespan. The nuances of operation and safety precautions will be addressed here, allowing you to harness the full potential of your tool. Learning the various features and settings can significantly improve your efficiency and precision in every project.

Emphasizing safety is paramount when working with any equipment that involves cutting mechanisms. Understanding the protective measures, correct handling, and troubleshooting techniques will empower you to operate your device with confidence. By following the guidelines outlined in this section, you can create with peace of mind and focus on achieving exceptional results.

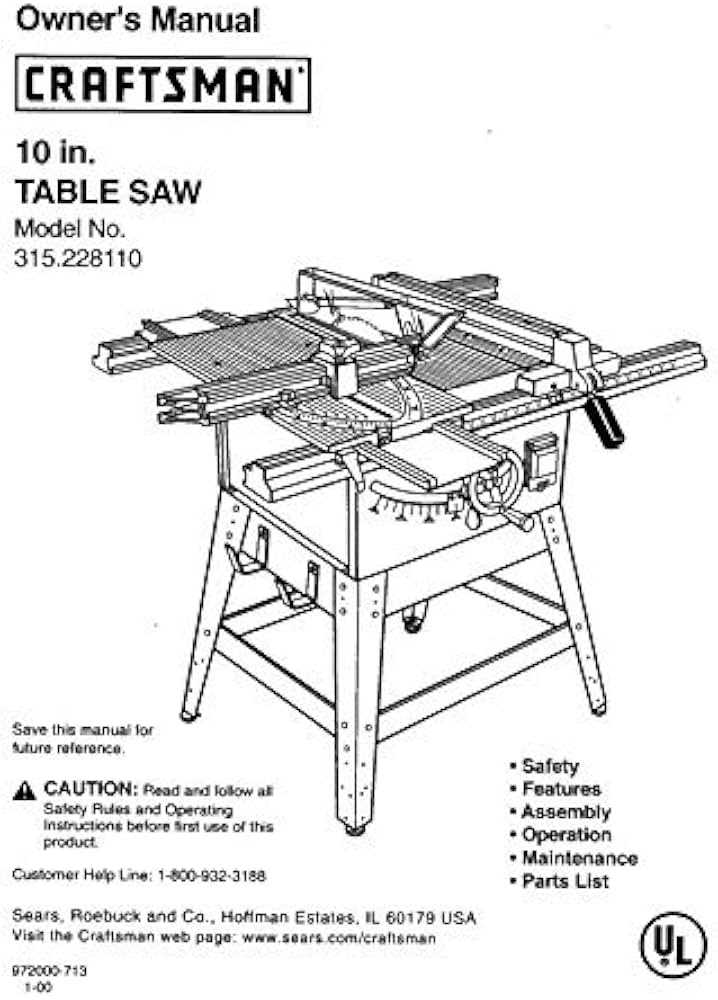

Understanding Your Craftsman Table Saw

Gaining insight into your precision cutting tool is essential for achieving optimal performance and safety. This guide aims to provide a comprehensive overview of the machine’s features, capabilities, and best practices to enhance your woodworking projects. Familiarizing yourself with the components and functions will enable you to utilize your equipment to its fullest potential.

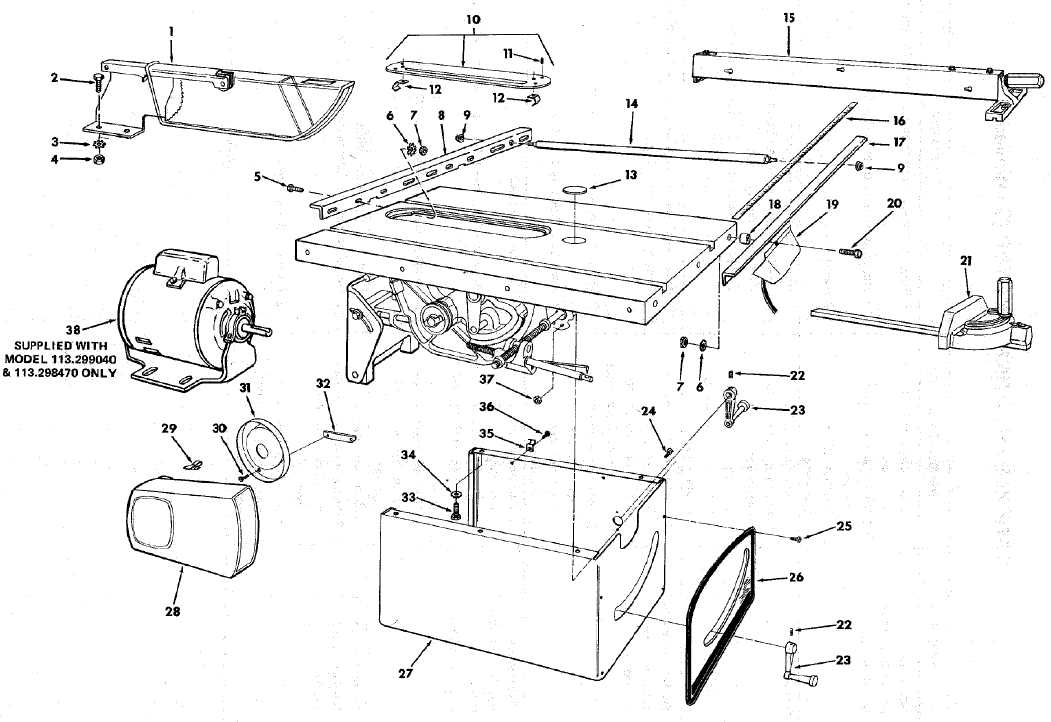

Components and Features

Your cutting device comprises several key parts, each contributing to its efficiency and effectiveness. The motor powers the blade, enabling it to slice through various materials with ease. The blade guard ensures safety by preventing accidental contact, while the fence system allows for accurate measurements and consistent cuts. Understanding how these elements work together is crucial for seamless operation.

Safety Practices

Prioritizing safety is paramount when working with any cutting apparatus. Always wear appropriate protective gear, including safety glasses and hearing protection. Ensure the workspace is clear of any obstructions, and double-check that all adjustments are secure before operating the machine. By adhering to these guidelines, you can create a safer environment and enjoy your projects without unnecessary risks.

Essential Safety Guidelines for Operation

Operating power equipment requires careful attention to safety protocols to prevent accidents and injuries. Adhering to established precautions is crucial for ensuring a secure work environment. This section outlines fundamental practices that every user should follow to maintain safety during use.

Before engaging with the machinery, it is vital to wear appropriate personal protective equipment, including safety glasses and hearing protection. Ensure the workspace is clean and free from any obstructions that could lead to hazards. Always inspect the equipment prior to use, checking for any damage or wear that might compromise its functionality.

Maintain focus and avoid distractions while operating the device. Never attempt to remove debris or make adjustments while the tool is still running. It is also important to keep hands and other body parts away from moving components to prevent injury. Utilize push sticks or other aids to handle materials, especially when working with smaller pieces.

In case of any malfunction, immediately turn off the equipment and seek assistance. Understanding the emergency shut-off mechanisms can significantly reduce response time in case of an incident. Always consult the accompanying guidelines for troubleshooting procedures and proper maintenance practices.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention. Implementing a consistent maintenance routine can significantly extend its lifespan and enhance efficiency. Below are essential practices to keep in mind.

- Regular Cleaning:

Dust and debris can accumulate over time, affecting functionality. Use a soft brush or cloth to clean surfaces regularly.

- Lubrication:

Applying the right lubricants to moving parts minimizes friction and wear. Check the manufacturer’s recommendations for suitable products.

- Inspection:

Frequent checks for any signs of wear or damage can help catch potential issues early. Look for loose components or unusual sounds during operation.

- Calibration:

Ensure that the settings are accurate and aligned correctly. Regular calibration enhances precision and ensures safety.

- Storage:

When not in use, store your equipment in a dry and secure location. Protecting it from moisture and dust will prevent premature deterioration.

By following these maintenance tips, you can ensure your device remains in excellent condition, providing reliable performance for years to come.