The following section aims to provide essential insights and guidance for individuals utilizing a specific type of automated garage mechanism. This resource is designed to enhance your understanding of the system’s functionality, maintenance, and troubleshooting, ensuring a seamless experience for all users.

With the right knowledge and tools at your disposal, you can confidently manage the operations of your garage setup. This guide covers crucial aspects, including installation tips, regular upkeep, and solutions to common issues that may arise during usage. By familiarizing yourself with these guidelines, you can maximize the efficiency and longevity of your automated access system.

In addition, the information provided will assist you in navigating various features that enhance convenience and security. Whether you’re a new user or have experience with automated garage systems, this comprehensive guide aims to empower you with the necessary skills and knowledge for effective management.

Understanding the mechanism that controls your vehicle entrance is crucial for ensuring its efficient operation and longevity. This section will explore the fundamental components and functionalities of these systems, offering insights into their maintenance and troubleshooting. A well-informed user can effectively address common issues and maximize the performance of their garage access solution.

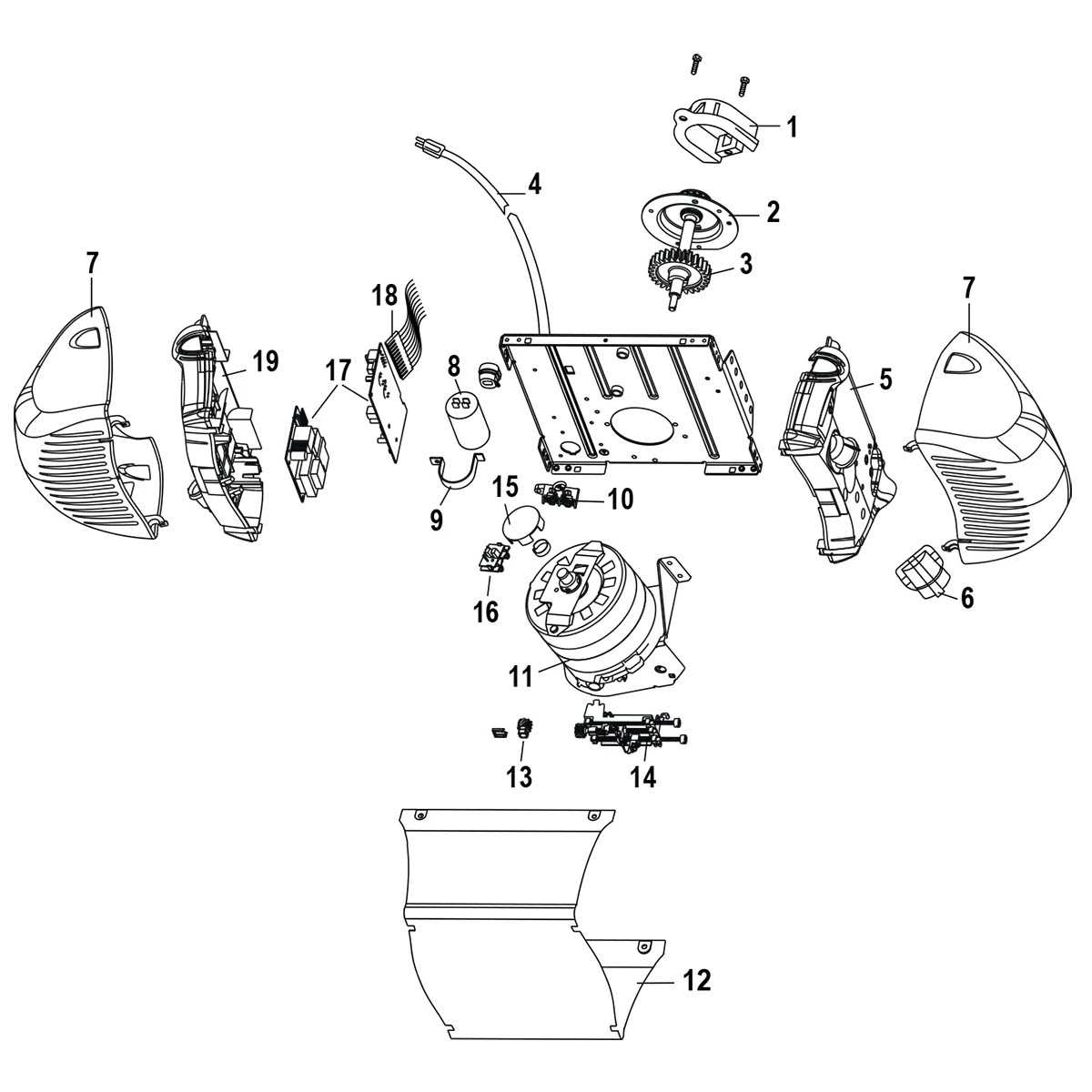

Key Components of the System

The following table outlines the primary elements of your garage door mechanism, detailing their functions and importance:

| Component | Function |

|---|---|

| Motor Unit | Drives the door up and down, providing the necessary power for operation. |

| Remote Control | Allows users to open or close the door from a distance, enhancing convenience. |

| Safety Sensors | Detect obstacles in the door’s path, preventing accidents and ensuring safe operation. |

| Track System | Guides the door’s movement, ensuring it opens and closes smoothly and securely. |

Basic Troubleshooting Tips

Regular upkeep can prevent many issues with your vehicle entrance system. Here are a few troubleshooting steps to consider:

- Check for any obstructions in the track.

- Ensure the power source is functioning correctly.

- Inspect the remote control batteries and replace them if necessary.

- Test the safety sensors for alignment and cleanliness.

Installation and Setup Instructions

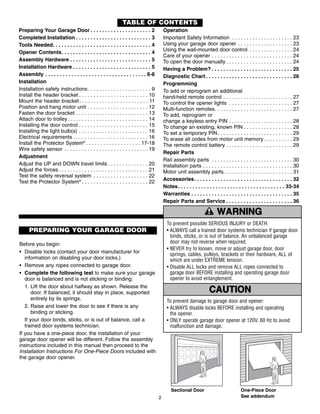

Setting up your system correctly is essential to ensure smooth and efficient operation. The process involves a series of clear steps that guide you from preparing the necessary components to final adjustments. This guide provides a straightforward approach to help you get everything in place without complications.

Preparing for Installation

Before beginning the installation, make sure all required tools and parts are readily available. A well-prepared workspace will save time and prevent delays.

- Ensure all components are present and undamaged.

- Gather basic tools such as a wrench, screwdriver, and ladder.

- Clear the working area for easy access.

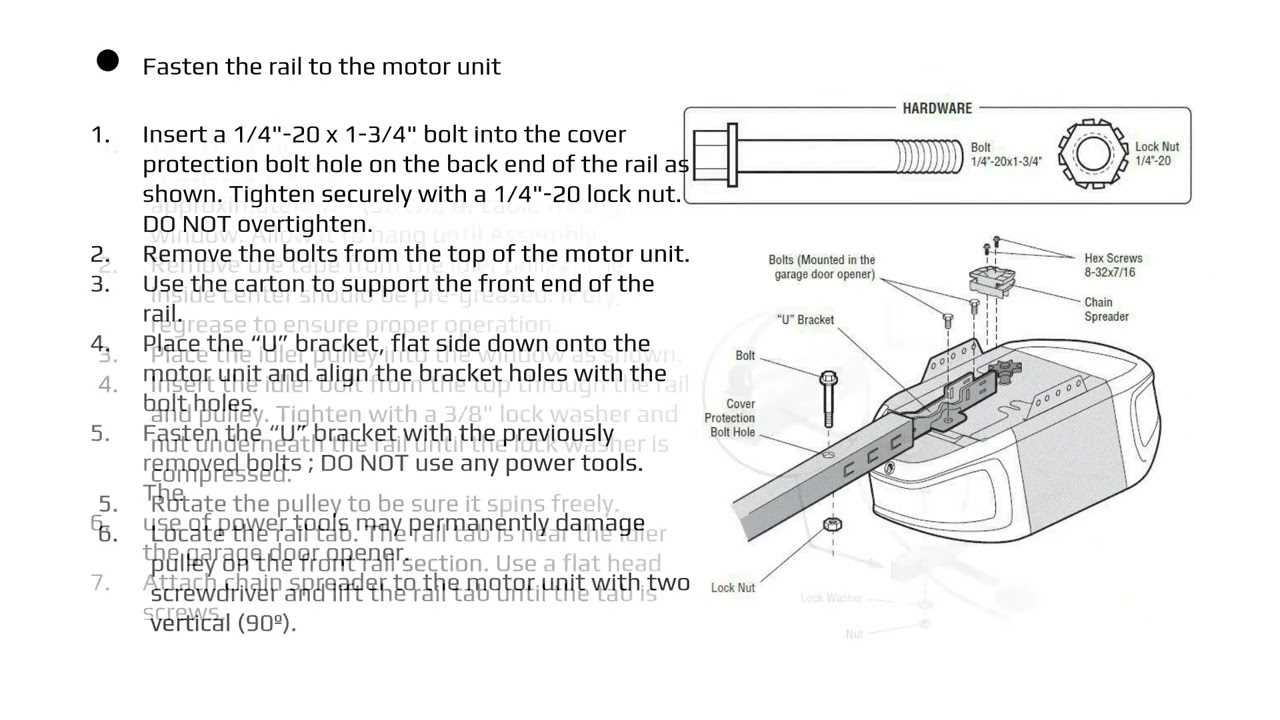

Step-by-Step Setup

- Start by securely mounting the main unit according to the provided measurements and alignments.

- Connect the appropriate power source, following the safety guidelines outlined in the instructions.

- Install any additional sensors or accessories that enhance the overall functionality.

- Test the unit after installation to ensure proper functioning, making necessary adjustments to sensitivity and motion settings.

Once these steps are completed, the setup should be fully operational, ready for daily use. Remember to periodically check the system’s performance to maintain its longevity and reliability.

For further information on related setup processes and troubleshooting guides, you might find user manuals from similar devices helpful or check online technical resources that offer detailed diagrams and video tutorials.

Troubleshooting Common Issues

Addressing frequent complications with your lifting mechanism can enhance its performance and longevity. Understanding typical problems and their solutions can save time and ensure smooth operation.

One common concern is the unresponsive system. If the unit fails to react to remote commands, check the power source and ensure all connections are secure. Additionally, verify that the batteries in the remote are functional and properly installed.

Another issue might be unusual noises during operation. Grinding or rattling sounds often indicate loose components or lack of lubrication. Inspect all moving parts and apply appropriate lubricants as necessary to maintain optimal performance.

Lastly, if the mechanism does not open or close fully, check the alignment of the tracks. Misalignment can cause the system to jam, preventing smooth operation. Adjust the tracks as needed to ensure proper alignment and functionality.