This section serves as a vital resource for individuals seeking to enhance their understanding of a specific piece of machinery. By providing essential insights and guidelines, it aims to empower users to operate and maintain their device with confidence and efficiency.

Within this guide, you will discover key operational procedures, troubleshooting tips, and maintenance advice designed to maximize the performance of your equipment. Knowledge is crucial when it comes to handling complex machinery, and this resource is crafted to support both novice and experienced users alike.

Moreover, the information provided will help in recognizing the features and functionalities that contribute to the overall effectiveness of your device. By following these carefully outlined instructions, you can ensure longevity and optimal performance, making your experience more rewarding and productive.

Overview of Case 75C Tractor Manual

This section provides a comprehensive examination of the documentation associated with a specific agricultural vehicle, focusing on essential information and guidelines necessary for effective operation and maintenance. The content serves as a resource for users seeking to maximize the performance and longevity of their machinery.

Understanding the details within this documentation is crucial for both new and experienced operators. It encompasses a variety of topics ranging from initial setup and troubleshooting to routine maintenance and safety precautions.

| Section | Description |

|---|---|

| Introduction | An overview of the vehicle’s features and specifications. |

| Operating Instructions | Step-by-step guidance on how to operate the machine safely and efficiently. |

| Maintenance Schedule | Recommended intervals and procedures for servicing the equipment. |

| Troubleshooting | Common issues and solutions to ensure optimal performance. |

| Safety Guidelines | Essential safety practices to follow during operation. |

By familiarizing oneself with this documentation, operators can ensure proper handling and care, ultimately leading to improved efficiency and reduced operational downtime.

Key Maintenance Tips for Case 75C

Regular upkeep is essential to ensure optimal performance and longevity of your machinery. By following some key practices, you can keep your equipment running smoothly and efficiently. Here are some vital tips to enhance the operational life of your machine.

Daily Checks

- Inspect fluid levels, including oil and coolant, to prevent overheating and ensure smooth operation.

- Examine the tires for proper inflation and wear to maintain traction and stability.

- Check all lights and signals to ensure visibility and safety during operation.

Scheduled Maintenance

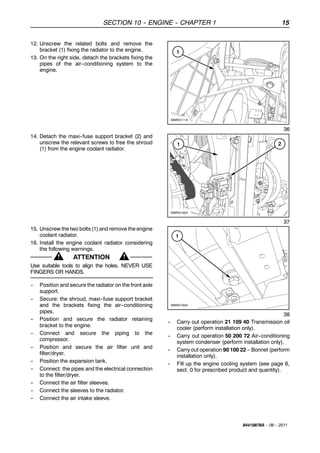

- Change the oil and filter at recommended intervals to protect engine components.

- Inspect and replace air filters to maintain optimal airflow and engine performance.

- Grease moving parts regularly to minimize wear and tear.

Implementing these maintenance practices will help you avoid costly repairs and maximize the efficiency of your equipment.

Operating Procedures for Case 75C

This section outlines the essential guidelines for effectively utilizing the machinery. Understanding the proper techniques and protocols ensures not only optimal performance but also enhances safety and longevity of the equipment. By following these procedures, operators can maximize efficiency while minimizing the risk of errors or accidents.

Preparation and Safety Measures

Before initiating any operations, ensure that the working environment is clear of hazards. Perform a thorough inspection of the equipment to identify any potential issues. Check fluid levels, brakes, and other critical components to guarantee everything is functioning correctly. Always wear appropriate personal protective equipment (PPE) to safeguard against possible injuries.

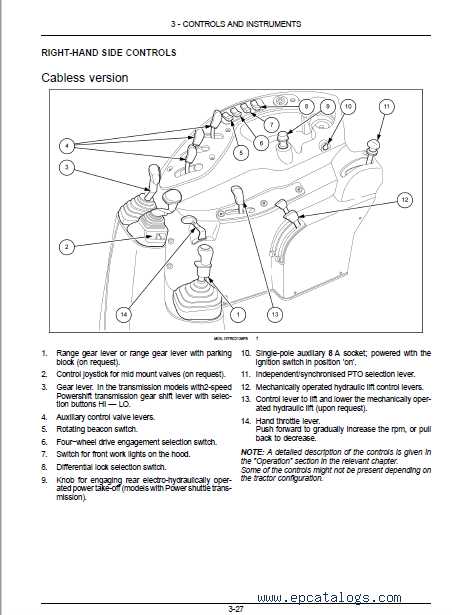

Operational Techniques

When starting the machine, follow the designated starting procedure to ensure smooth operation. Gradually engage the controls, allowing the equipment to acclimate to the load. Maintain awareness of the surrounding area and adjust your maneuvering techniques based on the terrain and conditions. Regularly monitor the machine’s performance indicators and make necessary adjustments to optimize productivity.