Understanding the intricacies of your machinery can significantly enhance its performance and longevity. This resource aims to provide you with comprehensive insights that will facilitate optimal usage and maintenance practices. Whether you are a seasoned expert or a novice, the information presented here is designed to be accessible and informative.

Proper maintenance and operation are key to ensuring your device functions efficiently. By delving into the details provided, users can learn how to troubleshoot common issues, follow safety protocols, and maximize the functionality of their unit. This guide will help you navigate through every aspect of your equipment with ease.

Ultimately, being well-informed about your machine not only saves time but also prevents costly repairs. Embrace the opportunity to enhance your skills and ensure your investment remains in peak condition for years to come.

Essential Features of Campbell Hausfeld Compressors

Understanding the core attributes of these machines can significantly enhance their usability and efficiency. Each model incorporates various elements designed to optimize performance and cater to diverse tasks.

Power Output: A crucial aspect, the energy produced directly impacts the ability to handle different tools and applications.

Tank Capacity: The size of the storage tank affects how long the unit can operate before needing to refill, making this a vital consideration for extended use.

Portability: Many designs feature wheels and handles, allowing for easy movement across work sites, which is essential for versatility.

Noise Level: Quiet operation is an important feature for many users, particularly in residential areas where sound restrictions apply.

Durability: Robust construction ensures longevity, allowing users to rely on the equipment for various projects without frequent repairs.

Ease of Maintenance: Simple maintenance protocols extend the lifespan and performance, ensuring that users can keep their units in peak condition.

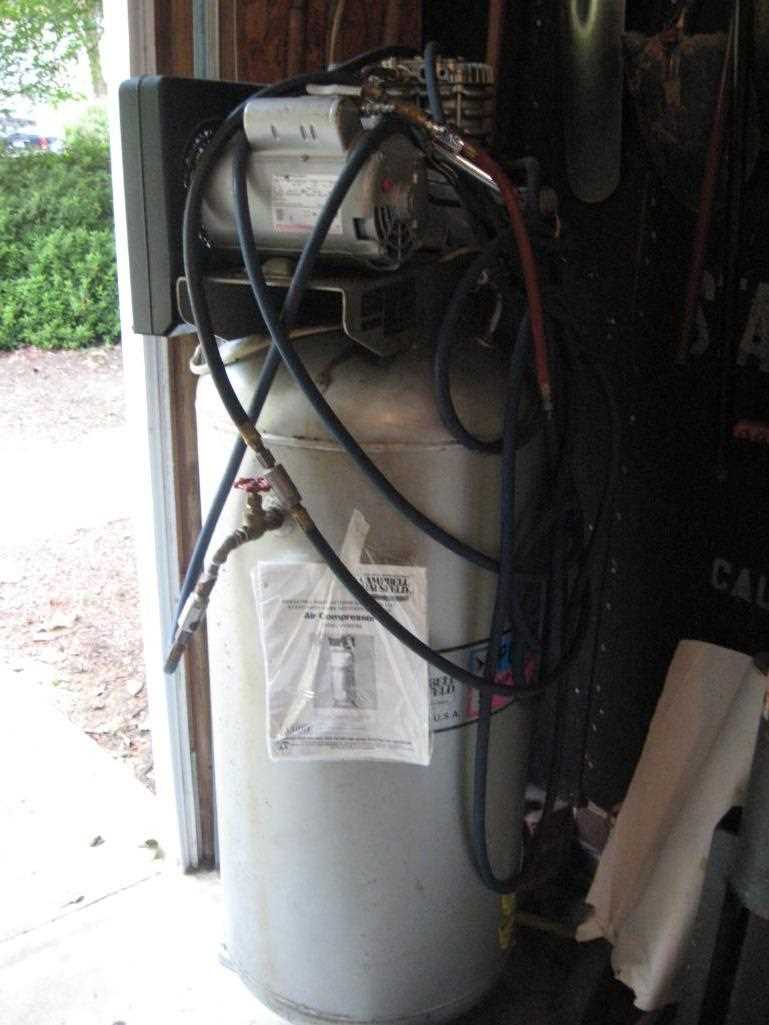

Maintenance Tips for Long-lasting Performance

Ensuring optimal functionality of your equipment involves regular upkeep and attention to detail. By implementing a few essential practices, you can significantly extend the lifespan and efficiency of your machine.

Routine Inspections

- Check for leaks or damage in hoses and fittings.

- Inspect the unit for any unusual sounds during operation.

- Regularly examine electrical connections for wear and corrosion.

Cleaning and Lubrication

- Remove dust and debris from filters to maintain airflow.

- Lubricate moving parts as recommended in the guidelines.

- Clean the exterior to prevent rust and deterioration.

By following these maintenance tips, you can delve into a proactive approach that will lead to ultimate performance and reliability.

Troubleshooting Common Compressor Issues

Addressing frequent problems can significantly enhance the performance and longevity of your equipment. Understanding typical challenges allows users to diagnose and resolve issues efficiently, minimizing downtime and ensuring optimal functionality.

One common problem is inadequate pressure. This may stem from leaks in hoses or connections, worn-out seals, or an improperly set regulator. Inspecting all components for wear and ensuring tight connections can often resolve this issue.

Another frequent concern is excessive noise during operation. This can be caused by loose parts, lack of lubrication, or issues with the motor. Regular maintenance, including tightening bolts and applying the appropriate lubricant, can help mitigate these noises.

Overheating is also a notable issue, often resulting from prolonged use or insufficient ventilation. Allowing the unit to cool down and ensuring proper airflow around the device can alleviate this problem.

If the device fails to start, check the power supply, fuses, and any safety switches that may have tripped. Ensuring that the power source is adequate can help avoid unnecessary interruptions.

Finally, if the unit is producing inconsistent output, it may indicate an obstruction in the intake or filter. Regular cleaning and maintenance of these components can restore performance and efficiency.