Understanding the functionality and maintenance of your cutting instrument is essential for achieving optimal performance. This section provides valuable insights into the various aspects of using and caring for your device, ensuring it remains efficient and effective over time.

Regular upkeep not only enhances the longevity of your equipment but also contributes to safety during operation. In the following sections, you will find detailed instructions and tips designed to assist you in mastering your tool while preventing common issues that may arise.

By familiarizing yourself with the recommended practices, you can confidently tackle your cutting tasks, whether they involve trimming branches, felling trees, or other projects. Embrace the knowledge that will empower you to handle your equipment with ease and expertise.

Before diving into the specifics of using your cutting tool, it’s crucial to have a clear grasp of its fundamental features and functions. This section will provide an overview of what makes this equipment unique and how it differs from other similar products. Understanding the various parts and their purposes will ensure safer and more efficient operation.

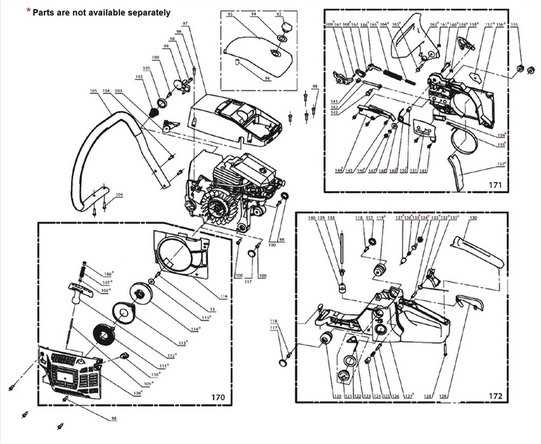

Key Components and Their Functions

- Engine Unit: The core component that drives the entire tool. Learn about the engine’s role and how it contributes to the device’s performance.

- Guide Bar: Essential for directing the cutting chain, the guide bar plays a vital role in ensuring precise cuts.

- Cutting Chain: This element is responsible for performing the actual cutting action. Familiarize yourself with its maintenance and care for optimal performance.

- Safety Features: These include mechanisms such as the chain brake and throttle lockout, designed to protect the user during operation.

Preparing for Use

- Inspection: Before starting, inspect the tool thoroughly to ensure all components are intact and properly assembled.

- Fuel and Lubrication: Check the fuel and oil levels, making sure they are adequate and suitable for the tool’s specifications.

- Starting Procedure: Follow the recommended steps for starting the tool safely, paying close attention to the initial setup and positioning.

With a solid understanding of these aspects, you’ll be better prepared to operate the equipment confidently and safely, minimizing the risk of accidents and maximizing its efficiency.

Safety Guidelines for Operation

Ensuring safe and efficient use of power tools is crucial for avoiding accidents and maintaining effective performance. This section provides important recommendations for secure operation, focusing on precautions that should be taken before, during, and after use to protect both the user and the equipment.

Pre-Use Inspection: Always conduct a thorough check of the tool before starting any task. Look for visible signs of wear or damage, and make sure all parts are properly secured. Verify that the equipment is in optimal working condition and that no components are loose or missing.

Proper Handling and Positioning: Maintain a firm and stable grip on the equipment at all times. Ensure a well-balanced stance, keeping both feet firmly planted. Avoid working in unstable or uneven areas where balance could be compromised.

Environmental Awareness: Be mindful of the surroundings. Remove any potential obstacles or debris from the working area. Ensure that bystanders, especially children and pets, are at a safe distance before beginning any operation.

Personal Protective Equipment (PPE): Wear appropriate safety gear, including protective eyewear, hearing protection, gloves, and suitable footwear. This reduces the risk of injury from flying debris or accidental contact with the tool.

Post-Use Maintenance: After completing the task, allow the tool to cool down before performing any maintenance. Clean the equipment thoroughly and store it in a safe, dry place out of reach of unauthorized individuals.

Maintenance Tips for Longevity

Regular upkeep is crucial to ensure the durability and optimal performance of your equipment. By following a few simple guidelines, you can extend the lifespan of your tool and maintain its efficiency over time. Proper care can also help prevent unexpected breakdowns and costly repairs.

- Keep It Clean: Regularly remove dirt, debris, and sawdust from all parts of the equipment. This prevents clogging and ensures smooth operation.

- Check and Replace Filters: Inspect the air and fuel filters frequently. Clean or replace them as needed to avoid blockages that can affect the engine’s performance.

- Lubricate Moving Parts: Apply appropriate lubricants to the chain and other moving components. This reduces friction and wear, contributing to a longer lifespan.

- Inspect the Chain: Regularly check the condition of the chain and adjust its tension as needed. Replace it if it’s worn out or damaged to ensure safe and efficient cutting.

- Sharpen the Cutting Edge: A sharp blade reduces strain on the motor and provides cleaner cuts. Keep the cutting edge sharpened and balanced for better performance.

- Fuel and Oil Quality: Always use high-quality fuel and oil. Poor-quality products can lead to deposits and reduced engine efficiency.

- Store Properly: When not in use, store the equipment in a dry and clean environment. This prevents rust and other environmental damage.

By adhering to these maintenance practices, you can ensure that your equipment remains in excellent working condition for years to come. Regular attention to these details will not only enhance performance but also reduce the need for frequent repairs.