Maintaining and operating classic agricultural machinery can be a rewarding experience for enthusiasts and professionals alike. These timeless machines, known for their robust design and functionality, play a vital role in farming history. Understanding the intricacies of their operation is crucial for anyone looking to preserve or utilize such equipment effectively.

Within this section, readers will find valuable insights into the features and specifications of a particular tractor model. Detailed descriptions and guidance will equip owners with the necessary knowledge to navigate common challenges and ensure optimal performance. This information serves as a comprehensive resource for those dedicated to keeping these historic machines running smoothly.

Whether you are a seasoned collector or a newcomer to the world of vintage tractors, the importance of having access to relevant instructions cannot be overstated. This guide aims to foster a deeper appreciation for these remarkable machines while providing practical tips for their upkeep and enhancement. Dive into the details and unlock the potential of your agricultural heritage.

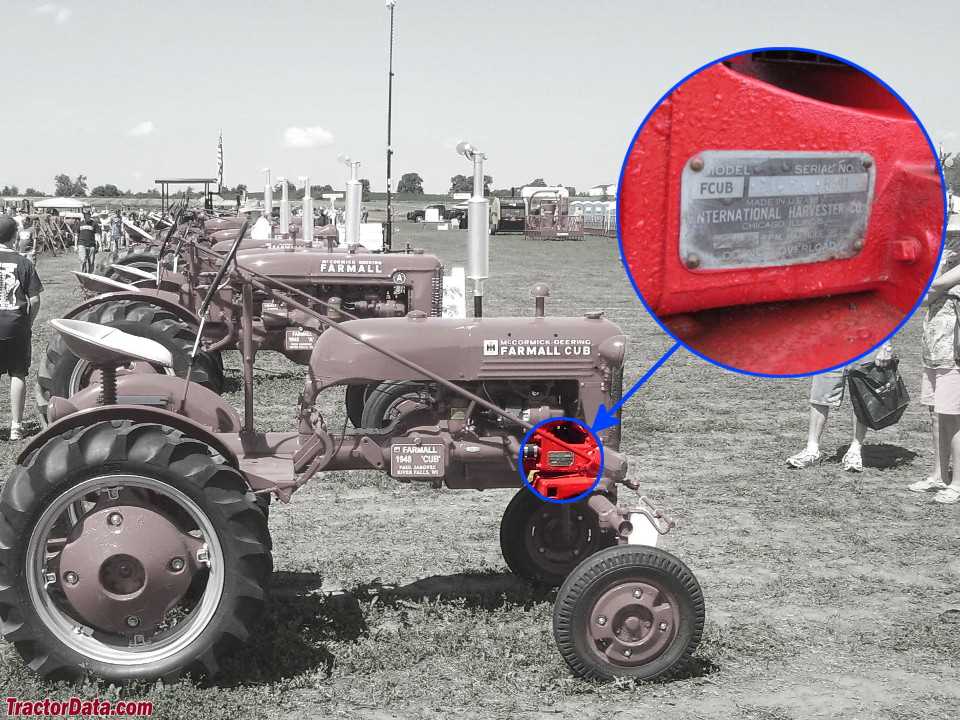

Essential Features of the 1949 Farmall Cub

This remarkable agricultural machine exemplifies simplicity and efficiency, making it a staple for small-scale farming operations. Designed with a focus on functionality, it combines power and ease of use, enabling farmers to tackle various tasks with minimal effort. Its compact size enhances maneuverability, allowing operators to navigate tight spaces with confidence.

Key Specifications

Understanding the vital specifications of this tractor can help potential users appreciate its capabilities and decide if it meets their farming needs.

| Specification | Detail |

|---|---|

| Engine Type | Four-cylinder gasoline engine |

| Horsepower | 12 HP at 1,600 RPM |

| Transmission | Sliding gear, 4-speed |

| Weight | 1,500 lbs (680 kg) |

| Fuel Capacity | 5 gallons (19 liters) |

Versatile Applications

This agricultural implement is designed for versatility, enabling it to perform a range of tasks, from plowing to hauling. Its adaptability allows farmers to customize attachments based on their specific requirements, maximizing productivity across different agricultural activities.

Maintenance Tips for Farmall Cub Owners

Regular upkeep is essential for maximizing the performance and longevity of your agricultural equipment. Proper attention to maintenance not only ensures efficiency but also minimizes the risk of unexpected breakdowns. By implementing a consistent maintenance routine, you can enjoy a reliable and effective machine for many years.

1. Routine Inspections: Frequently examine your machine for any signs of wear or damage. Look for leaks, loose components, and signs of corrosion. Early detection of issues can save time and money in repairs.

2. Fluid Levels: Always check and maintain proper fluid levels, including engine oil, coolant, and hydraulic fluid. Regularly changing these fluids according to the manufacturer’s recommendations will help keep the engine running smoothly.

3. Cleanliness: Keep your equipment clean to prevent dirt and debris from causing wear. Regularly wash the exterior and ensure that air filters are clean to maintain optimal airflow and performance.

4. Tire Care: Maintain proper tire pressure and inspect tires for any signs of damage or excessive wear. Rotating tires can also help distribute wear evenly and prolong their lifespan.

5. Scheduled Servicing: Adhere to a maintenance schedule based on usage and manufacturer guidelines. Scheduled servicing can include oil changes, filter replacements, and other critical checks that ensure the machinery operates efficiently.

6. Storage Practices: When not in use, store your equipment in a dry, sheltered area to protect it from the elements. Use covers when necessary to prevent dust accumulation and exposure to moisture.

By following these essential maintenance tips, you can enhance the reliability and efficiency of your agricultural machinery, ensuring it serves you well for years to come.

Common Issues and Solutions for Operators

When operating vintage agricultural machinery, various challenges may arise. Understanding these common problems and their solutions can significantly enhance the user experience and prolong the life of the equipment. Here, we address frequent issues encountered by operators and provide practical solutions to ensure smooth operation.

Engine Performance Problems

One of the most prevalent concerns relates to engine performance. This can manifest as difficulties starting the machine or a noticeable decrease in power while in use. Here are some potential causes and remedies:

- Issue: Difficulty starting the engine.

Solution: Check the fuel system for clogs and ensure the fuel is fresh. Examine the battery and electrical connections for corrosion or damage. - Issue: Engine misfires or stutters during operation.

Solution: Inspect the spark plugs and ignition system. Replacing worn or faulty plugs can often resolve these issues. - Issue: Overheating of the engine.

Solution: Ensure the cooling system is functioning correctly. Check coolant levels and inspect hoses for leaks or blockages.

Transmission and Gear Issues

Transmission difficulties can also hinder productivity. These issues might include gear slipping or difficulty shifting. Here are some common problems and solutions:

- Issue: Gears slipping during operation.

Solution: Examine the transmission fluid levels and condition. Low or contaminated fluid can lead to shifting problems; replacing it may restore proper function. - Issue: Difficulty engaging gears.

Solution: Check the linkage and adjust if necessary. Inspect for any obstructions or wear in the gear mechanism. - Issue: Noisy transmission.

Solution: Look for signs of wear in the gears and bearings. Replacing damaged parts can reduce noise and improve performance.