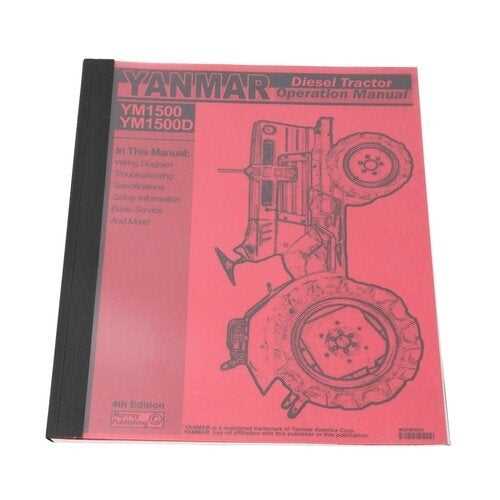

When managing a compact agricultural vehicle, understanding its functionalities and maintenance requirements is essential for ensuring longevity and efficiency. This section provides a comprehensive overview aimed at enhancing the user’s experience and knowledge about their machinery.

Equipping oneself with the necessary information can significantly impact performance and safety. By familiarizing oneself with operational techniques and routine care practices, owners can maximize productivity and minimize potential issues. This resource serves as a valuable reference for users seeking to optimize their agricultural equipment.

Through careful attention to these insights, operators will be better prepared to tackle challenges and ensure smooth functionality throughout their machinery’s lifespan. The following guidelines will assist in achieving an effective and reliable operation.

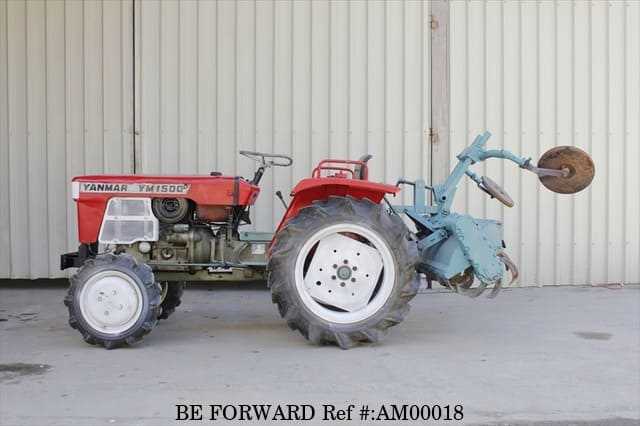

Yanmar YM1500 Overview and Features

This section explores the key characteristics and functionalities of a compact agricultural machine designed for various tasks. Its robust design and efficiency make it a valuable asset for both small farms and personal projects.

Key Characteristics

- Powerful engine for enhanced performance

- Compact size, ideal for tight spaces

- User-friendly controls for easy operation

Functionalities

- Excellent maneuverability in diverse terrains

- Versatile attachment compatibility for various tasks

- Fuel-efficient design, reducing operational costs

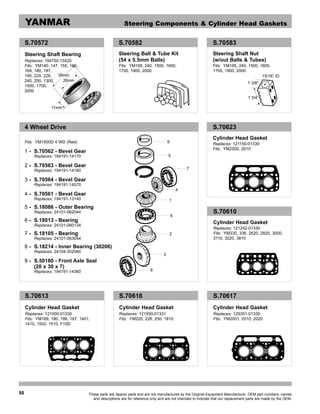

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. By following a few straightforward practices, you can enhance performance and minimize potential issues.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace engine oil to maintain lubrication and prevent wear. |

| Filter Inspection | Every 50 hours | Check air and fuel filters for clogs to ensure optimal airflow and fuel flow. |

| Coolant Level Check | Weekly | Monitor coolant levels to avoid overheating and ensure proper engine temperature. |

| Battery Maintenance | Monthly | Inspect battery connections and clean terminals to prevent corrosion. |

| Belts and Hoses | Every 100 hours | Examine for wear or cracks to prevent breakdowns. |

Common Issues and Troubleshooting Guide

This section addresses frequent challenges faced by users and offers solutions to enhance operational efficiency. Understanding these common obstacles can significantly improve the experience and prolong the lifespan of your machinery.

Here are some typical problems and their corresponding troubleshooting steps:

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Engine won’t start | Insufficient fuel, battery failure, or ignition problems | Check fuel levels, inspect the battery connections, and test the ignition system. |

| Overheating | Low coolant, blocked radiator, or malfunctioning thermostat | Ensure coolant is at the correct level, clean the radiator, and check the thermostat. |

| Poor performance | Clogged air filter, dirty fuel injectors, or improper tire pressure | Replace the air filter, clean or replace fuel injectors, and check tire inflation. |

| Unusual noises | Loose components, worn belts, or internal damage | Tighten loose parts, replace worn belts, and consult a professional for internal inspections. |