This section provides essential insights for individuals seeking to optimize the performance and longevity of their cutting equipment. Understanding the functionality and maintenance of your tool is crucial for achieving efficient operation and ensuring safety during use.

Effective usage is key to maximizing the capabilities of your device. By familiarizing yourself with the various features and settings, you can enhance your experience and accomplish tasks with ease. Regular upkeep is equally important; it helps to prevent potential issues and promotes a longer lifespan for your equipment.

Furthermore, safety protocols should always be prioritized. Utilizing protective gear and following recommended practices will safeguard you during operation. This guide aims to equip you with the necessary knowledge and skills to handle your equipment confidently and responsibly.

Understanding the Stihl MS250C Features

The featured model in question is designed for optimal performance and user convenience, embodying a range of functionalities that enhance both efficiency and safety during operation. With a combination of innovative technology and ergonomic design, this tool is well-suited for various cutting tasks.

Powerful Engine: At the heart of this machine lies a robust engine that provides ample power for demanding applications. This high-performance unit ensures effective cutting while maintaining fuel efficiency, making it ideal for both professional and recreational use.

Lightweight Design: The thoughtful construction of this model contributes to its lightweight nature, allowing for easy handling and reduced fatigue during extended use. This is especially beneficial for users who require prolonged operation without compromising comfort.

Enhanced Safety Features: Safety is paramount in tool design, and this model includes various features aimed at protecting the operator. With an advanced braking system and a secure grip design, users can operate confidently while minimizing risks associated with cutting tasks.

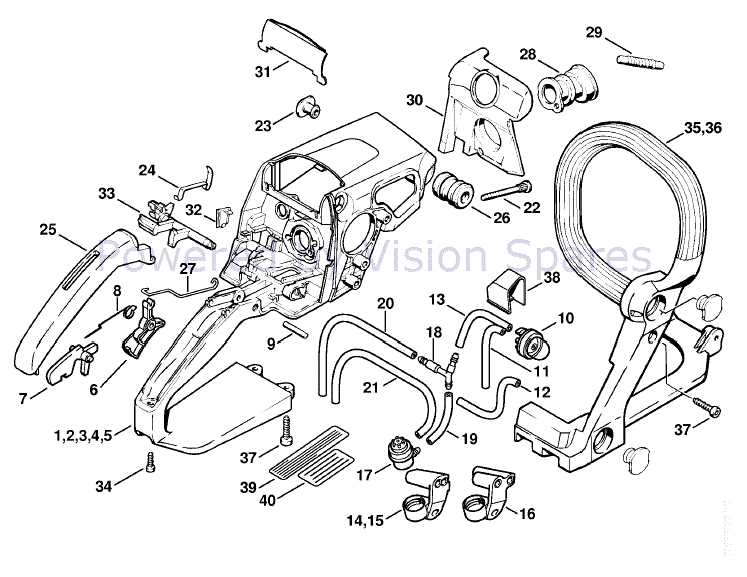

Easy Maintenance: Regular upkeep is essential for long-lasting performance, and this tool is equipped with features that facilitate straightforward maintenance. Access to key components is simplified, allowing users to keep their equipment in top condition with minimal effort.

Versatile Applications: This equipment is versatile enough to handle a wide array of tasks, from pruning and trimming to felling larger trees. Its adaptability makes it a valuable addition to any toolkit, catering to various user needs.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your power equipment. Regular maintenance not only enhances the efficiency of the device but also extends its operational lifespan. Adhering to a few key practices can prevent wear and tear and promote reliability over time.

Firstly, routine cleaning is crucial. After each use, remove any debris, such as dirt and sawdust, from the exterior and air filter. This helps prevent clogging and maintains optimal airflow. Additionally, regularly inspect the chain and bar for signs of damage or excessive wear, and replace them as necessary to ensure smooth operation.

Lubrication is another important aspect. Regularly apply oil to the chain and bar to reduce friction and prevent overheating. Check the oil level frequently and top it up as needed. Furthermore, ensure that the fuel used is fresh and of high quality to avoid engine issues.

Finally, periodic professional servicing can identify potential problems before they escalate. Consulting a qualified technician for routine check-ups can help maintain optimal performance and prolong the life of your equipment.

Troubleshooting Common Issues

This section focuses on identifying and resolving frequent problems that users may encounter while operating their equipment. Understanding these issues can enhance performance and prolong the lifespan of the machine.

Engine Fails to Start: If the engine does not start, ensure that the fuel is fresh and that the correct mixture has been used. Additionally, check the spark plug for signs of wear or damage. Cleaning or replacing the spark plug may resolve the issue.

Excessive Vibration: Excessive vibration can indicate that the cutting attachment is unbalanced or improperly mounted. Inspect the attachment for damage and ensure it is securely attached to the drive shaft.

Stalling During Operation: If the equipment stalls frequently, it may be a sign of a clogged air filter. Cleaning or replacing the air filter can improve airflow and help maintain consistent performance.

Poor Cutting Performance: Dull blades can significantly affect cutting efficiency. Regularly inspect the cutting tools and sharpen them as needed. Additionally, ensure that the correct settings are adjusted for the material being cut.

Fuel Leakage: If fuel leaks are detected, inspect the fuel lines and connections for cracks or damage. Replacing any damaged components will help prevent leaks and ensure safe operation.

By following these troubleshooting tips, users can effectively address common issues and maintain optimal functionality of their equipment.