Maintaining your garden tools is essential for optimal performance and longevity. This section provides valuable insights into the effective use and care of a popular model in the trimming equipment category. Understanding the features and functions of your device can significantly enhance your gardening experience.

For those who rely on their machines for yard maintenance, familiarizing yourself with operational guidelines is crucial. This information will not only assist in day-to-day usage but also ensure safety while working. Knowing the specifications and recommended practices will empower you to tackle various landscaping tasks with confidence.

Additionally, troubleshooting common issues can save time and resources. By exploring maintenance tips and best practices, you can prevent potential problems and extend the life of your tool. This guide aims to equip you with the knowledge needed to get the most out of your equipment.

Essential Features of Stihl FS45

This section explores the key characteristics that make this cutting tool highly efficient and user-friendly. Understanding these features can enhance your experience and optimize performance during maintenance tasks.

Performance Attributes

- Powerful engine for effective cutting

- Lightweight design for ease of use

- Quick-start technology for instant operation

User-Friendly Design

- Ergonomic handle for comfortable grip

- Adjustable shaft length for different users

- Easy access to maintenance points for hassle-free servicing

Maintenance Tips for Optimal Performance

Regular upkeep is essential for achieving the best functionality and longevity of your equipment. By following a few straightforward practices, you can ensure that your device runs smoothly and efficiently over time.

1. Clean the Air Filter: A clean air filter enhances airflow, which is vital for optimal engine performance. Check and clean or replace the filter as necessary.

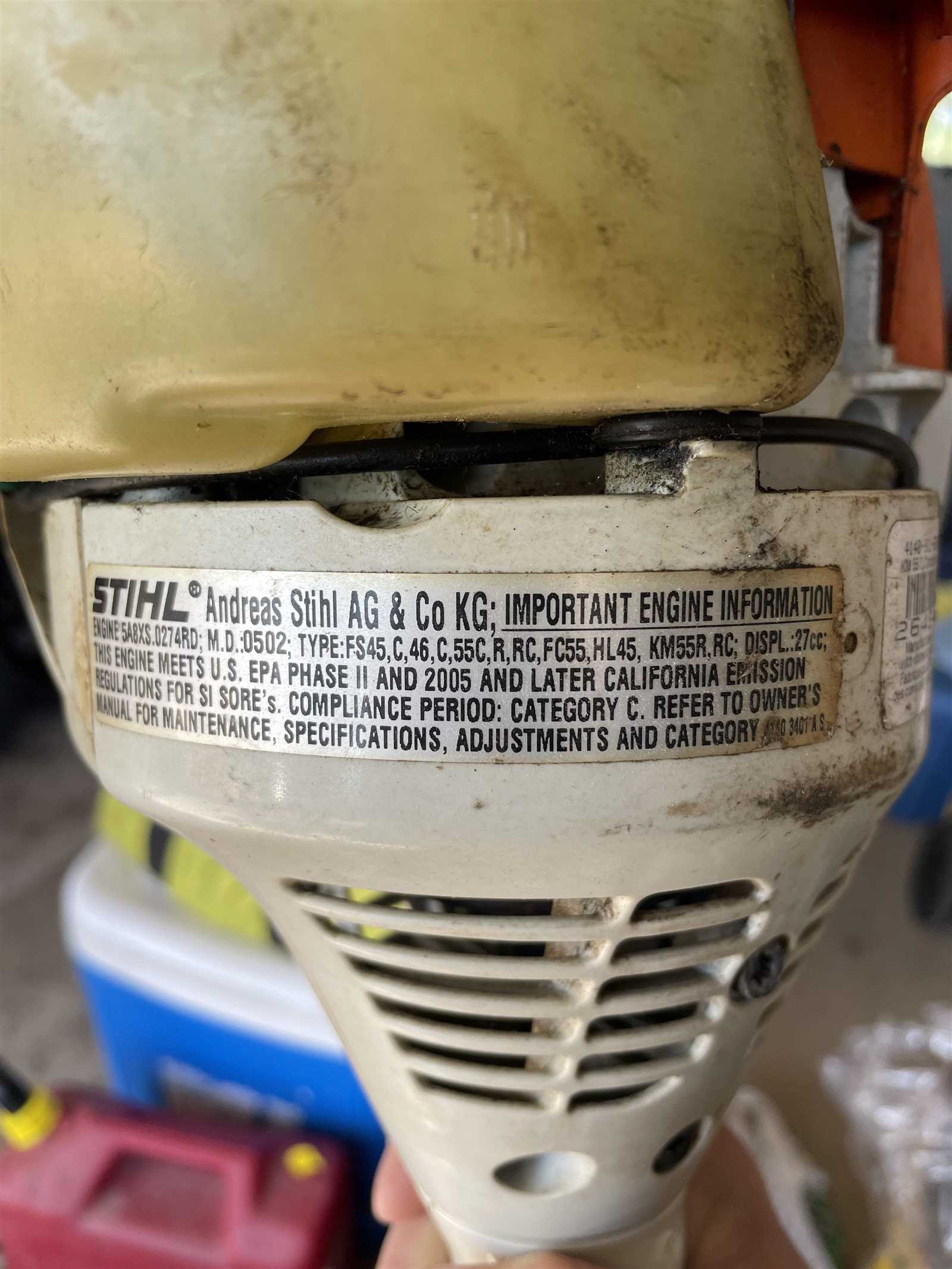

2. Inspect the Spark Plug: Regularly examine the spark plug for wear and buildup. Replacing a worn spark plug can improve ignition and fuel efficiency.

3. Fuel Quality: Always use fresh, high-quality fuel to prevent engine issues. Consider adding a fuel stabilizer if the device will be idle for an extended period.

4. Blade Maintenance: Keep blades sharp and free of debris. Dull blades can strain the engine and reduce cutting efficiency.

5. Lubrication: Regularly lubricate moving parts to minimize wear and tear. Use appropriate lubricants to ensure optimal functioning.

6. Regular Inspections: Frequently check for loose or damaged components. Addressing issues early can prevent costly repairs and ensure reliable operation.

By adhering to these maintenance tips, you can maximize the performance and lifespan of your equipment, ensuring it operates at its ultimate best.

Common Issues and Troubleshooting Guide

This section aims to address frequent problems encountered with outdoor power tools and offers practical solutions for users. By understanding these common challenges, you can enhance your equipment’s performance and longevity.

Typical Problems

- Engine won’t start

- Inconsistent power during operation

- Excessive vibration

- Fuel leaks

Troubleshooting Steps

- Check fuel levels and quality.

- Inspect the air filter for clogs.

- Examine the spark plug for wear.

- Ensure all connections are secure.

By following these guidelines, users can effectively troubleshoot and resolve common issues, ensuring optimal performance.