Understanding your machinery is crucial for maintaining optimal performance and longevity. This section provides essential insights and guidance, ensuring that you can effectively operate and care for your device. By familiarizing yourself with the various components and their functions, you can enhance your overall experience.

In this comprehensive overview, we delve into important maintenance tips and operational instructions. Emphasizing safety and efficiency, the information presented here aims to empower users, allowing for confident handling of the equipment. Proper knowledge leads to improved functionality and prevents potential issues that may arise during use.

As you explore this resource, you will discover valuable techniques for troubleshooting and enhancing your machinery’s capabilities. Equipped with the right information, you can ensure your device remains in top condition, providing reliable performance for years to come.

Essential Features of MTD Snowblowers

The equipment designed for removing snow is equipped with a variety of important characteristics that enhance its performance and user experience. These features are specifically engineered to tackle various winter conditions efficiently, ensuring that pathways and driveways remain clear of snow and ice.

Power and Efficiency

One of the standout attributes of this machinery is its robust engine, which provides the necessary strength to manage heavy snowfall. The powerful motor contributes to effective clearing, allowing for quick and efficient operations even in challenging weather conditions.

User-Friendly Design

Additionally, the thoughtful design of the controls and features promotes ease of use. Adjustable chute angles and simple steering mechanisms ensure that users can navigate with precision. Enhanced mobility and control significantly reduce the effort required to operate the device, making winter maintenance much more manageable.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring efficient functionality and longevity of your equipment. By adhering to a consistent maintenance schedule, users can prevent potential issues and enhance the overall operation of their machinery.

Routine Checks

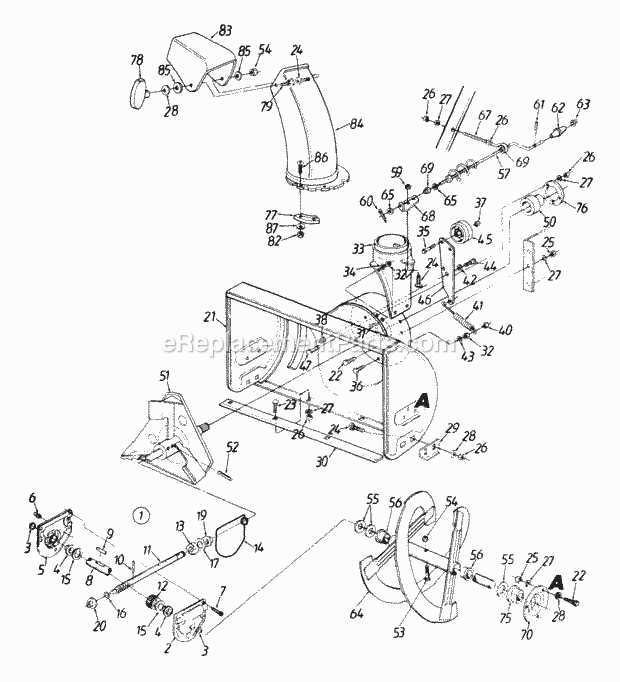

- Inspect the condition of belts and cables for signs of wear or damage.

- Examine the cutting components for sharpness and integrity.

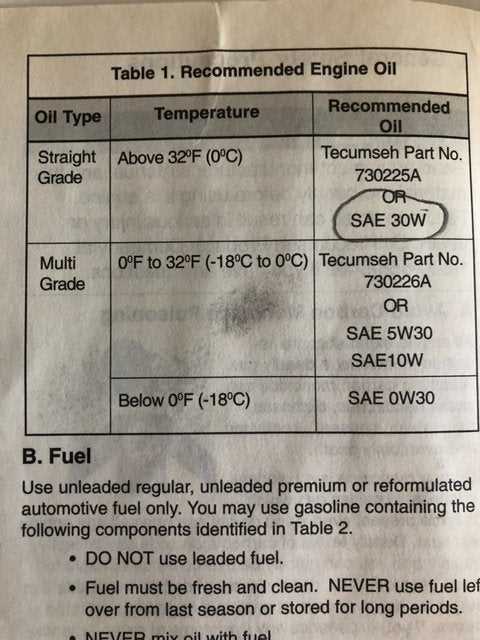

- Monitor fluid levels, including oil and fuel, to maintain optimal performance.

- Check for loose bolts and fasteners, tightening them as necessary.

Seasonal Preparation

- Prior to the onset of the cold season, ensure thorough cleaning to remove debris and dirt.

- Apply rust-resistant spray on metal parts to protect against corrosion.

- Store the unit in a dry place to prevent moisture-related issues.

Safety Guidelines for Operation

Ensuring a secure working environment is crucial when engaging with outdoor equipment. Adhering to fundamental safety protocols not only protects the user but also enhances the efficiency of the tasks at hand. Familiarity with safety measures can significantly reduce the risk of accidents during operation.

Pre-Operational Checks

Before commencing any activity, it is essential to inspect the machinery thoroughly. Check for any signs of wear or damage, ensuring that all components are functioning correctly. Make sure to read the instructions carefully and be aware of the features that enhance safety during use. Proper maintenance is key to preventing malfunctions that could lead to injuries.

Personal Protective Equipment

Wearing appropriate safety gear is a vital aspect of operation. This includes gloves, goggles, and sturdy footwear to safeguard against potential hazards. Always prioritize your well-being by avoiding loose clothing that could get caught in moving parts. Taking these precautions can help maintain a secure environment while enhancing performance.