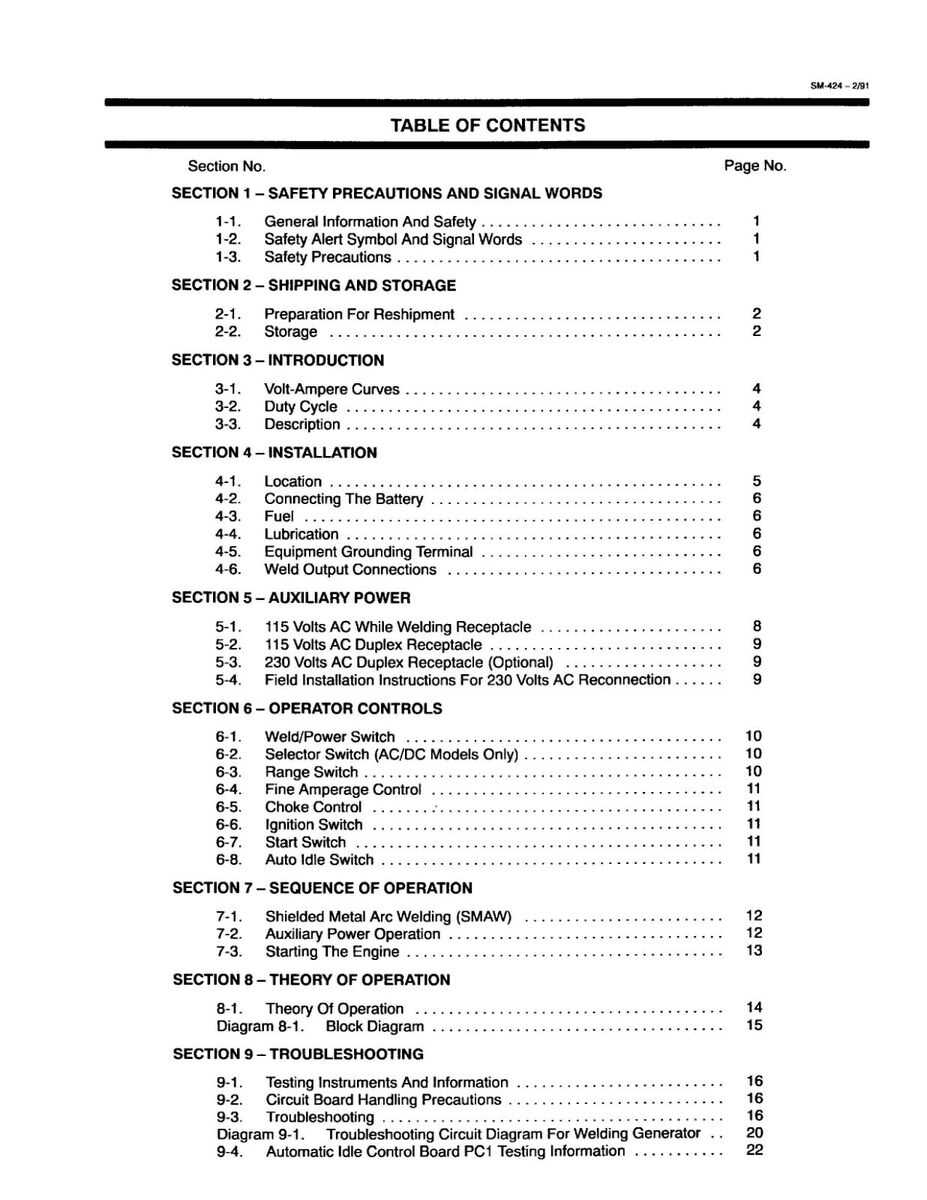

Understanding the operation and maintenance of your equipment is essential for optimal performance and longevity. This section provides detailed insights into the features and functionalities of your device, ensuring you can utilize it to its full potential. Knowledge of the various components and their roles is crucial for any user aiming to achieve efficiency and effectiveness in their tasks.

In the subsequent paragraphs, you will discover valuable information on setup procedures, operational guidelines, and troubleshooting tips. By familiarizing yourself with these aspects, you can enhance your experience and reduce the likelihood of errors during use. A well-informed operator is key to maximizing the benefits of any machinery, leading to improved results and satisfaction.

Additionally, this guide aims to address common inquiries and challenges that users may encounter. With a focus on practical advice and best practices, you will gain the confidence needed to manage your equipment proficiently. Empowering yourself with knowledge is the first step towards successful and safe operation.

This section provides an overview of a versatile power source designed for various applications. Understanding its features and functionalities can greatly enhance the user experience and ensure optimal performance in different environments.

- Power Output: The device delivers a reliable output suitable for welding and powering equipment.

- Portability: Its lightweight design facilitates easy transportation, making it ideal for job sites.

- Fuel Efficiency: Engineered to maximize fuel usage, it minimizes operating costs.

Grasping the operational characteristics and maintenance requirements is crucial for ensuring longevity and effectiveness. Users should familiarize themselves with the following aspects:

- Setup Process: A step-by-step guide to properly initiating the equipment.

- Safety Protocols: Important measures to follow to avoid accidents during operation.

- Routine Maintenance: Suggested practices to keep the machinery in optimal condition.

In conclusion, understanding the essential elements of this power source will empower users to utilize it effectively, ensuring successful outcomes in their projects.

Key Features and Specifications

This section provides an overview of the essential characteristics and technical details of the portable welding machine. Understanding these features is crucial for users looking to maximize efficiency and performance in various welding applications.

Performance Capabilities

The equipment is designed to deliver reliable output across a range of welding processes. It boasts adjustable voltage settings, enabling users to fine-tune the machine according to specific requirements. Additionally, it supports both direct current (DC) and alternating current (AC) modes, making it versatile for different materials and environments.

Durability and Portability

Constructed with robust materials, this device ensures longevity even under demanding conditions. Its compact design enhances portability, allowing users to transport it easily to various job sites. Furthermore, the inclusion of a built-in handle facilitates hassle-free movement, making it suitable for both professional and personal use.

Maintenance and Safety Guidelines

Proper upkeep and adherence to safety measures are crucial for ensuring the longevity and efficient operation of your equipment. Following established protocols not only enhances performance but also minimizes risks associated with its use.

Regular maintenance tasks should include:

- Inspecting components for wear and damage.

- Cleaning surfaces to prevent buildup of dirt and debris.

- Checking fluid levels and replacing them as needed.

- Testing electrical connections to ensure proper functionality.

Safety precautions are vital to protect both the user and the machinery. Key guidelines include:

- Always wear appropriate personal protective equipment (PPE).

- Ensure the work area is clean and free of hazards.

- Follow manufacturer instructions for operation.

- Be aware of your surroundings and avoid distractions while working.

By implementing these maintenance practices and safety guidelines, you can ensure a reliable performance and reduce the likelihood of accidents during operation.