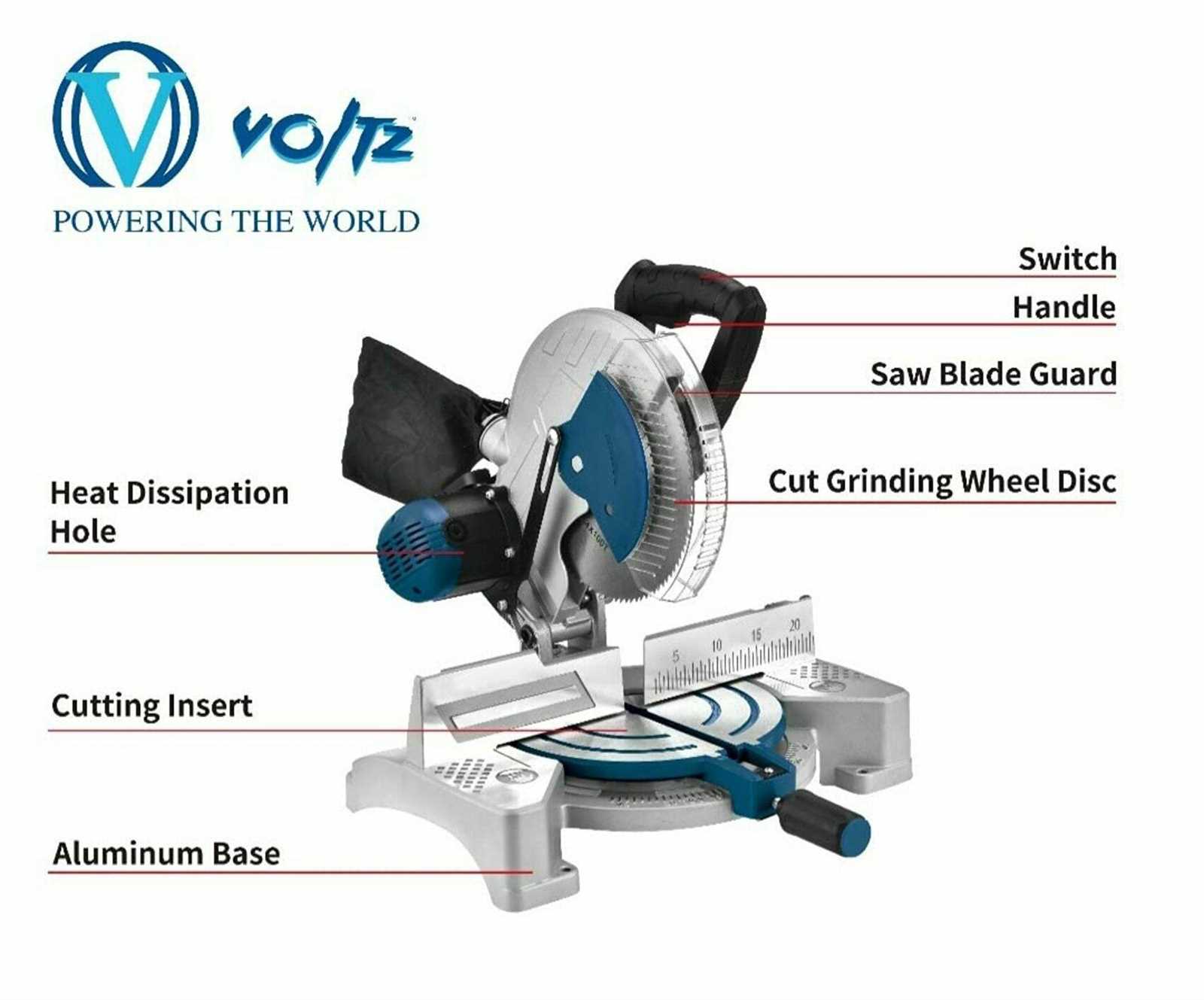

When working with advanced cutting equipment, understanding the essential components and functions is crucial for achieving precise results. This section serves as a comprehensive resource for users, providing insights into the operational features and maintenance practices necessary for optimal performance.

Regular upkeep and familiarization with the tool’s capabilities not only enhance your woodworking experience but also ensure safety during use. Mastering the techniques outlined here will empower you to tackle various projects with confidence, whether you are a novice or an experienced craftsman.

In addition to operational tips, this guide covers troubleshooting common issues that may arise, helping you to maintain the longevity and efficiency of your equipment. By following the recommendations provided, users can maximize their productivity and achieve high-quality results in their woodworking endeavors.

When handling any power tool, safety should always be the top priority. Understanding the basic principles of safe operation ensures not only the longevity of the equipment but also the well-being of the operator. Following standard safety protocols can significantly reduce the risk of accidents and ensure smooth operation.

Personal Protective Equipment

Always wear proper gear, including safety glasses, hearing protection, and dust masks. Loose clothing, jewelry, or long hair should be secured to avoid entanglement. Protective gloves may be required depending on the nature of the task being performed.

Work Area Safety

Ensure the workspace is clean and well-lit. Avoid working in damp or wet conditions, and keep the area free of distractions. A stable surface is essential to avoid tool misalignment and potential hazards during operation.

| Precaution | Reason |

|---|---|

| Use the correct blade for the task | Reduces the risk of kickback and uneven cuts |

| Disconnect power before adjustments | Prevents accidental startup during maintenance |

| Check for damaged parts regularly | Ensures safe and reliable performance |

Maintenance Tips for Longevity

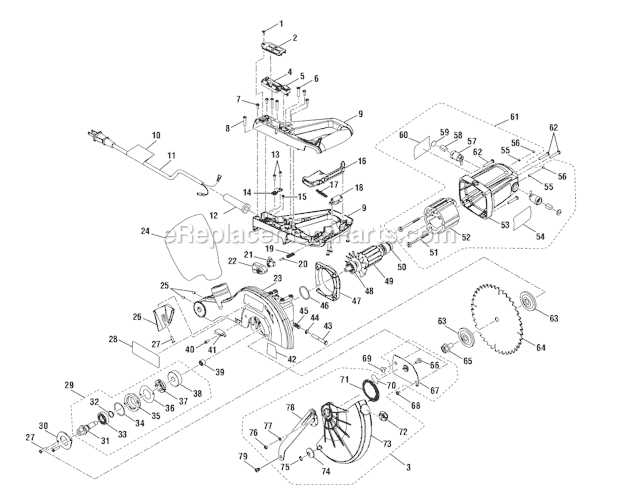

Proper care and regular upkeep are essential for maximizing the lifespan of your cutting tool. By implementing a few straightforward practices, you can ensure optimal performance and durability over time.

Here are some effective maintenance strategies:

- Regular Cleaning: Keep the equipment free from dust and debris. Use a soft brush or cloth to wipe down surfaces after each use.

- Blade Inspection: Frequently check the cutting edge for any signs of wear or damage. Replace dull or chipped blades promptly to maintain cutting efficiency.

- Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer. This reduces friction and prevents wear.

- Calibration: Ensure that your tool is properly calibrated. Regularly check alignment and make adjustments as necessary to ensure precision.

- Storage: Store the equipment in a dry, protected area to prevent rust and corrosion. Consider using a cover to shield it from dust and moisture.

By following these simple yet effective tips, you can enhance the functionality and lifespan of your cutting tool, ensuring reliable performance for years to come.