Managing your outdoor machinery effectively can significantly enhance your gardening experience. This section is designed to provide you with essential insights into the operational features and maintenance practices necessary for optimal performance.

Understanding the functionalities of your equipment is crucial for achieving desired results. By familiarizing yourself with various settings and tools, you can ensure efficient operation and prolong the lifespan of your machinery.

Regular upkeep and care play a vital role in maintaining the efficiency of your devices. Implementing a consistent maintenance schedule not only safeguards your investment but also ensures that you can tackle any task with ease and confidence.

Overview of John Deere X495 Features

This section highlights the distinctive characteristics of a renowned lawn care machine, emphasizing its innovative design and functionality. Users can expect a robust performance that enhances the efficiency of yard maintenance tasks.

Power and Performance

Equipped with a powerful engine, this model ensures excellent torque and speed, making it suitable for various terrains. Its advanced transmission system allows for seamless gear shifting, providing a smooth driving experience.

Versatile Attachments

The flexibility of this machine is enhanced by its compatibility with a range of attachments. Whether it’s mowing, snow removal, or landscaping, owners can easily switch tools to tackle different jobs effectively.

Maintenance Tips for Optimal Performance

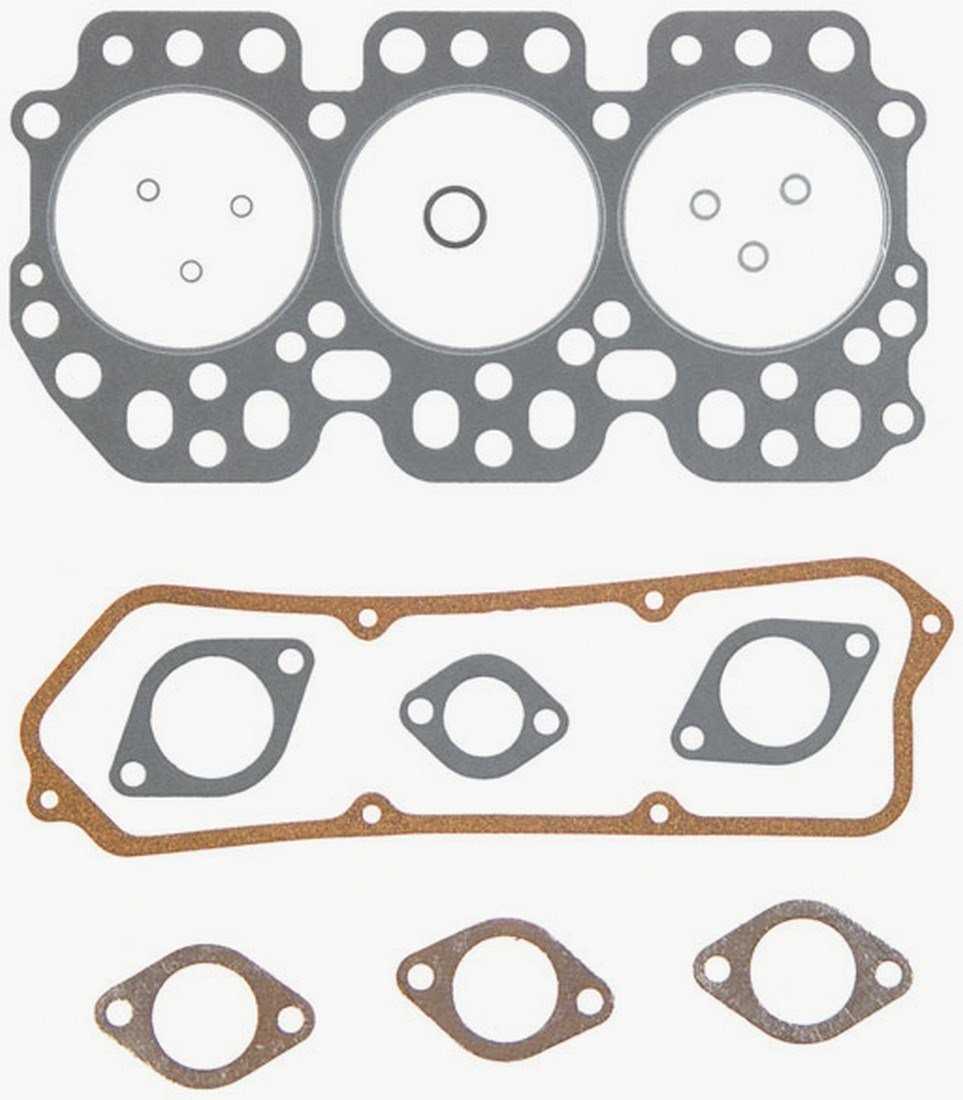

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By adhering to a structured maintenance routine, you can enhance performance and reduce the likelihood of costly repairs.

Routine Inspections: Frequently check all components for wear and tear. Address any issues promptly to prevent further damage.

Fluid Changes: Regularly replace oils and filters to keep the engine running smoothly. Clean fluids contribute to optimal functioning and prevent buildup.

Cleaning: Keep the exterior and interior free from debris. A clean machine operates better and is less prone to issues.

Tire Maintenance: Monitor tire pressure and tread wear. Properly inflated tires ensure better traction and fuel efficiency.

Sharpening Blades: Maintain sharp blades for efficient cutting. Dull blades can lead to increased strain on the engine and poorer performance.

By implementing these maintenance strategies, you can maximize the efficiency and lifespan of your machinery, ensuring it performs at its best for years to come.

Common Issues and Troubleshooting Solutions

Understanding typical challenges and their resolutions is essential for maintaining optimal performance of your equipment. This section outlines frequent problems encountered by users and offers practical solutions to enhance usability.

- Engine Won’t Start:

- Check the fuel level and ensure it’s fresh.

- Inspect the battery connections and charge status.

- Examine the ignition switch and wiring for damage.

- Uneven Cutting:

- Ensure the blades are sharp and properly aligned.

- Adjust the cutting height for uniformity.

- Inspect tire pressure for consistent traction.

- Overheating:

- Check for debris in the cooling system.

- Inspect the oil level and quality.

- Clean or replace the air filter as necessary.

Regular maintenance and prompt attention to these issues can significantly improve the longevity and efficiency of your equipment.