Maintaining your machinery is crucial for ensuring optimal performance and longevity. Understanding the intricacies of your device can significantly enhance its functionality and reliability. This section will provide insights into the various aspects of care and usage.

From basic operations to troubleshooting common issues, having a comprehensive resource at your disposal can make all the difference. Equipped with the right knowledge, users can confidently navigate their tasks and make informed decisions.

In this guide, we will cover essential tips and practices to help you maximize the efficiency of your equipment. Whether you’re a seasoned operator or new to the experience, these insights will empower you to maintain your device effectively.

This section aims to provide valuable insights into the operation and maintenance of your lawn equipment. By understanding its features and functions, you can enhance its performance and longevity.

Key Features

- Powerful engine for efficient cutting

- Ergonomic design for comfortable handling

- Adjustable cutting heights for versatile grass management

Maintenance Tips

- Regularly check and change the oil to ensure optimal performance.

- Inspect and sharpen blades to maintain a clean cut.

- Clean the undercarriage to prevent grass buildup and rust.

By following these guidelines, you can ensure that your equipment operates smoothly and remains in top condition for years to come.

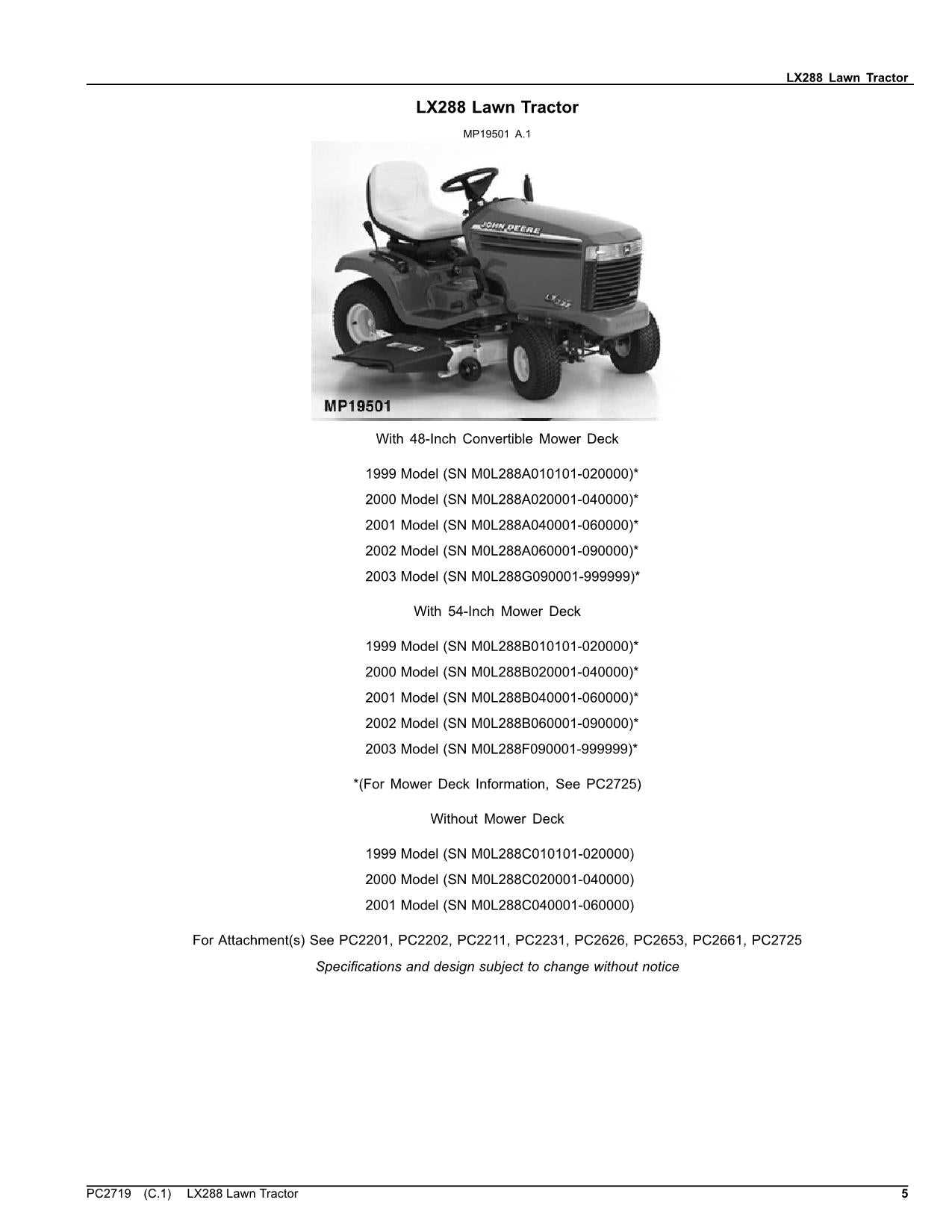

Key Features and Specifications

This section highlights the essential attributes and technical details of the lawn tractor, providing insights into its design and functionality.

| Feature | Description |

|---|---|

| Engine Type | Powerful air-cooled engine designed for efficiency and durability. |

| Cutting Width | Available with various deck sizes for versatile mowing options. |

| Transmission | Smooth automatic transmission for effortless driving experience. |

| Fuel Capacity | Generous tank size to support extended operation without frequent refills. |

| Turning Radius | Compact design allows for tight turns and maneuverability in small spaces. |

Maintenance Tips for Longevity

Ensuring the durability of your equipment involves regular upkeep and thoughtful practices. By adopting a proactive approach, you can significantly extend the life of your machine and enhance its performance over time.

Regular Cleaning: Keep your device clean from debris and dirt. Regularly washing the exterior and ensuring that components are free from buildup can prevent wear and tear.

Routine Inspections: Conduct frequent checks to identify any potential issues early. Look for signs of wear, loose parts, or any abnormalities that may need immediate attention.

Lubrication: Proper lubrication of moving parts is essential for smooth operation. Use the recommended lubricants to reduce friction and minimize the risk of damage.

Proper Storage: Store your equipment in a dry, sheltered location to protect it from harsh weather conditions. Covering it can also prevent dust accumulation.

Timely Replacements: Replace worn-out components promptly to avoid further damage. Keeping spare parts on hand can facilitate quick repairs and minimize downtime.

Common Troubleshooting Issues

This section addresses typical problems that may arise during the operation of your machine, along with potential solutions to enhance its performance. Understanding these common challenges can help maintain optimal functionality and prolong the lifespan of your equipment.

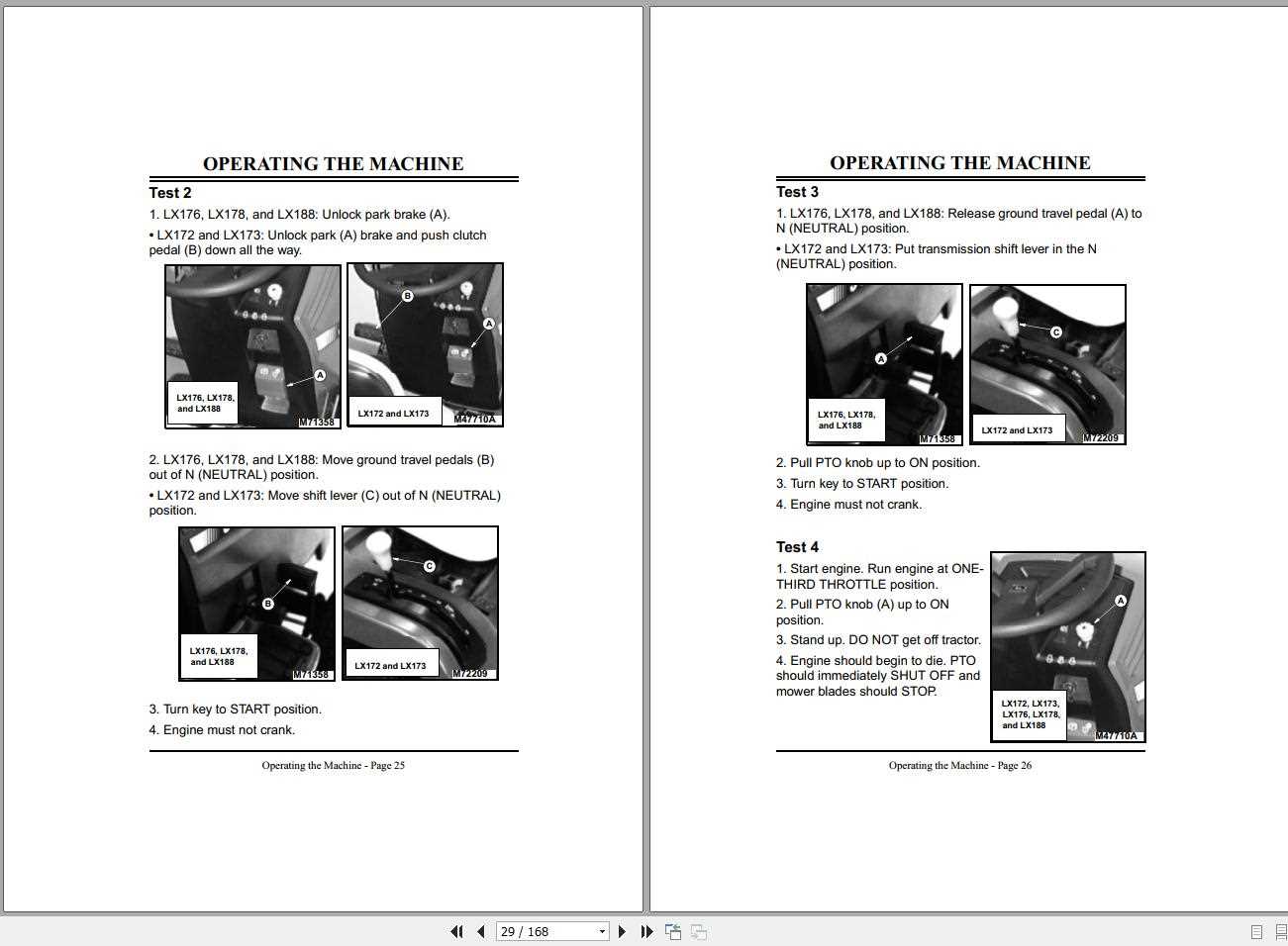

One frequent issue encountered is difficulty in starting the engine. This may stem from a drained battery, faulty ignition components, or insufficient fuel. Checking the battery connections and ensuring the fuel system is functioning correctly can often resolve this problem.

Another common concern involves uneven cutting. This can result from dull blades or improper deck height settings. Regularly sharpening blades and adjusting the cutting height according to the manufacturer’s guidelines will help achieve a uniform cut.

Lastly, if the machine exhibits unusual noises or vibrations, it may indicate loose parts or wear in mechanical components. Conducting routine inspections and tightening any loose fasteners can prevent further complications and ensure smooth operation.