Proper handling and care of your equipment is essential for achieving optimal performance and extending its lifespan. Knowing how to operate it correctly not only ensures safety but also enhances functionality during everyday use.

This section will provide comprehensive guidance on essential operational procedures, regular maintenance routines, and tips for troubleshooting common issues. By following the recommended practices, you can ensure that your machinery remains in top condition, reducing the need for frequent repairs or replacements.

Whether you are new to this type of equipment or an experienced user, understanding the core principles of its operation and care will help you make the most of your investment, ensuring consistent performance in a variety of conditions.

Overview and Features

This model stands out due to its efficiency and versatility in handling various outdoor tasks. Designed for optimal performance, it offers an easy-to-use interface combined with reliable durability, making it suitable for both small and larger areas. Its robust construction ensures longevity and consistent functionality in different conditions.

Performance: One of the key highlights is its powerful engine, capable of delivering a smooth and efficient operation. Whether dealing with uneven terrain or challenging weather, this machine maintains a stable output.

Usability: The intuitive design emphasizes comfort and ease of use. With adjustable settings and user-friendly controls, it caters to both novice and experienced operators.

Maintenance: Routine upkeep is simplified through accessible components, reducing the time and effort required for regular checks. This ensures long-term reliability and optimal performance.

Maintenance Guidelines for Optimal Performance

To ensure the longevity and efficiency of your equipment, regular maintenance is essential. Proper care will not only extend the lifespan of the machine but also improve its overall functionality. Consistent attention to key areas will prevent wear and tear, minimizing the likelihood of breakdowns.

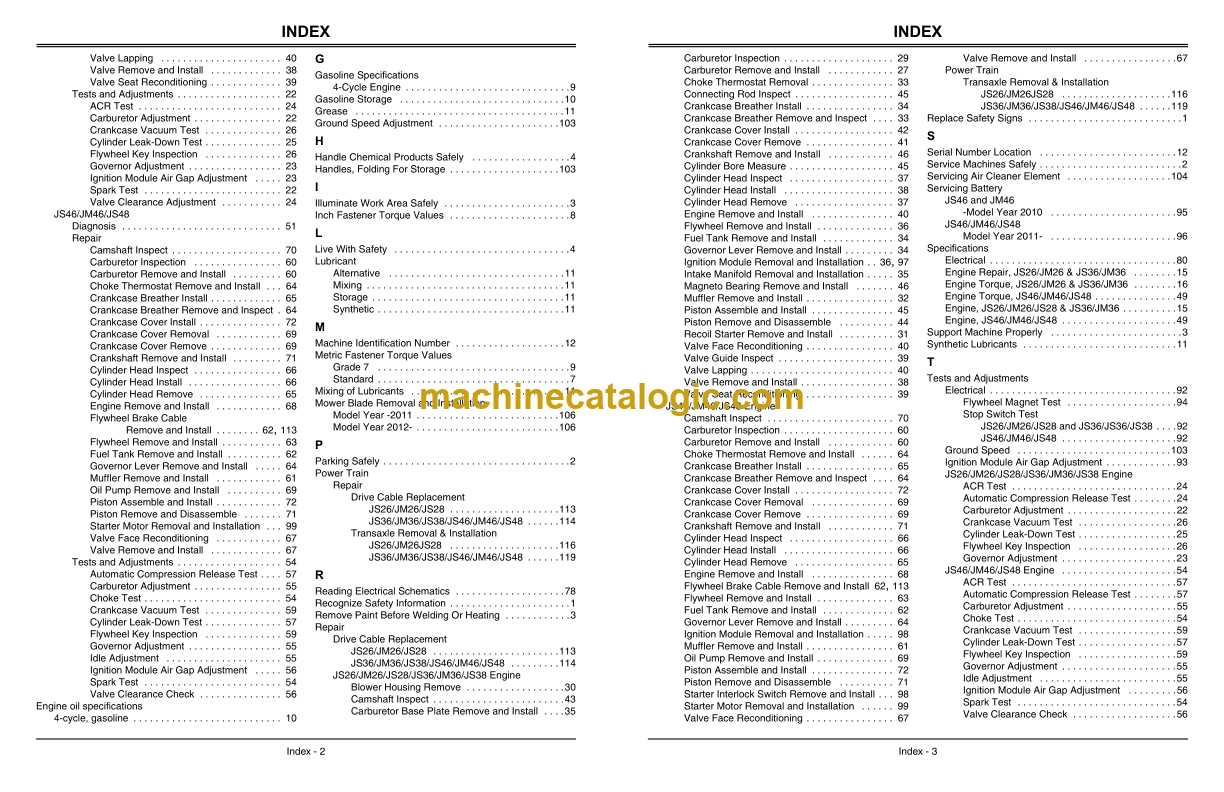

Routine Inspection

It is important to perform regular checks on critical components. Pay attention to parts that experience the most stress and friction, such as the engine, blades, and belts. Keeping these elements clean and lubricated will reduce unnecessary strain and keep the equipment running smoothly.

Cleaning and Lubrication

Ensure that the machine is cleaned after every use to prevent dirt and debris from causing blockages or damage. Lubricate moving parts as specified to reduce friction and prolong the life of the mechanical components.

| Component | Maintenance Task | Frequency |

|---|---|---|

| Engine | Check oil level, clean air filter | Before each use |

| Blades | Inspect for wear, sharpen as needed | Monthly |

| Belts | Inspect for cracks

Common Troubleshooting Tips for JS46

When handling equipment for lawn care, it’s essential to be prepared for occasional challenges. Most issues arise due to wear, incorrect settings, or external factors like debris. Regular maintenance and understanding common problems can help ensure smooth operation. Engine Starting Issues: If the engine struggles to start, check the fuel system for blockages and ensure the air filter is clean. Replacing a dirty spark plug may also resolve ignition problems. Uneven Cutting: Uneven grass cutting may indicate dull blades or improper deck leveling. Sharpening the blades and adjusting the cutting deck can often fix this. Stalling During Operation: Frequent stalling might be caused by a clogged fuel line or insufficient oil levels. Clean the fuel line and top up the oil as needed. By following these simple checks, you can avoid larger issues and maintain your equipment’s performance effectively. |