Understanding the complexities of operating a versatile agricultural vehicle is essential for maximizing its potential. This section aims to provide valuable insights and practical tips that will help users navigate through various functionalities and maintenance procedures.

With an emphasis on reliability and efficiency, the information presented here will enhance your experience with this powerful machine. Whether you are a seasoned operator or new to the field, you’ll find guidance tailored to suit your needs.

In addition, we explore troubleshooting techniques and best practices that ensure your equipment remains in optimal condition. Emphasizing a proactive approach can save time and resources, allowing for seamless agricultural operations.

Overview of John Deere 4510 Features

This section provides a comprehensive look at the key characteristics of a popular compact utility tractor. Designed for versatility and efficiency, this machine combines power with user-friendly features, making it suitable for various tasks in agricultural and landscaping settings.

The model boasts a robust engine, offering reliable performance while maintaining fuel efficiency. Its transmission system ensures smooth gear shifts, enhancing operational control. Additionally, the ergonomic design of the operator station allows for comfort during extended use, promoting productivity.

With a range of attachments and implements available, this tractor adapts easily to different applications, from mowing to tilling. The excellent visibility and maneuverability further contribute to its appeal, making it a valuable asset for both professionals and hobbyists alike.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. By adhering to a structured maintenance routine, you can prevent issues before they arise and enhance overall functionality. Here are some key practices to keep in mind.

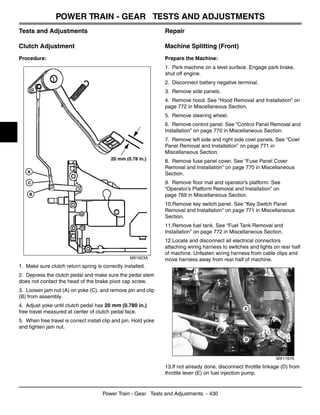

Routine Inspections

Conduct frequent checks on various components to identify wear and tear. Pay attention to fluids, filters, and belts, as these are crucial for optimal operation.

Fluid Management

Maintaining the correct levels of fluids is vital. Regularly replace oil and coolant to keep the engine running smoothly. Follow the recommended intervals for fluid changes.

| Fluid Type | Recommended Change Interval |

|---|---|

| Engine Oil | Every 100 hours |

| Coolant | Every 2 years |

| Hydraulic Fluid | Every 500 hours |

Common Issues and Troubleshooting Guide

This section addresses frequent challenges encountered by users of specific agricultural machinery, offering practical solutions and insights. By understanding typical problems, operators can enhance their efficiency and reduce downtime.

Engine Starting Issues: Difficulty in starting the engine is a common complaint. Ensure that the fuel tank is full and the battery is adequately charged. If problems persist, check the starter motor and wiring for any faults.

Hydraulic System Malfunctions: If the hydraulic system is unresponsive, inspect the fluid levels and look for leaks in hoses and connections. Regular maintenance of hydraulic components is essential for optimal performance.

Overheating: Overheating can lead to severe engine damage. Check the coolant level and ensure that the radiator is clean and unobstructed. Regularly inspect the fan and thermostat for proper operation.

Unusual Noises: Any unexpected sounds can indicate mechanical issues. Investigate the source of the noise, focusing on belts and bearings. Prompt attention can prevent more significant repairs.