Understanding the intricacies of heavy equipment is crucial for maximizing performance and longevity. This section provides a comprehensive overview aimed at individuals seeking to enhance their operational knowledge and skills. By familiarizing yourself with the best practices, you can ensure optimal functionality and safety during usage.

Effective management of such machinery not only boosts efficiency but also mitigates the risk of unexpected issues. This guide covers vital aspects, including maintenance schedules, troubleshooting techniques, and operational guidelines, tailored specifically for users of powerful excavation tools.

Equipping yourself with detailed insights empowers operators to handle their equipment confidently. With proper care and attention, you can maintain peak performance, ensuring that your machinery remains a reliable asset for all your projects.

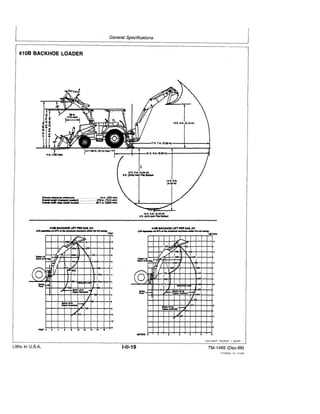

Understanding Your John Deere 410 Backhoe

Familiarizing yourself with your construction equipment is essential for maximizing its performance and ensuring longevity. This section aims to provide insights into the operational features, maintenance requirements, and safety protocols associated with your machine. A solid grasp of these elements can enhance your efficiency and prevent potential issues.

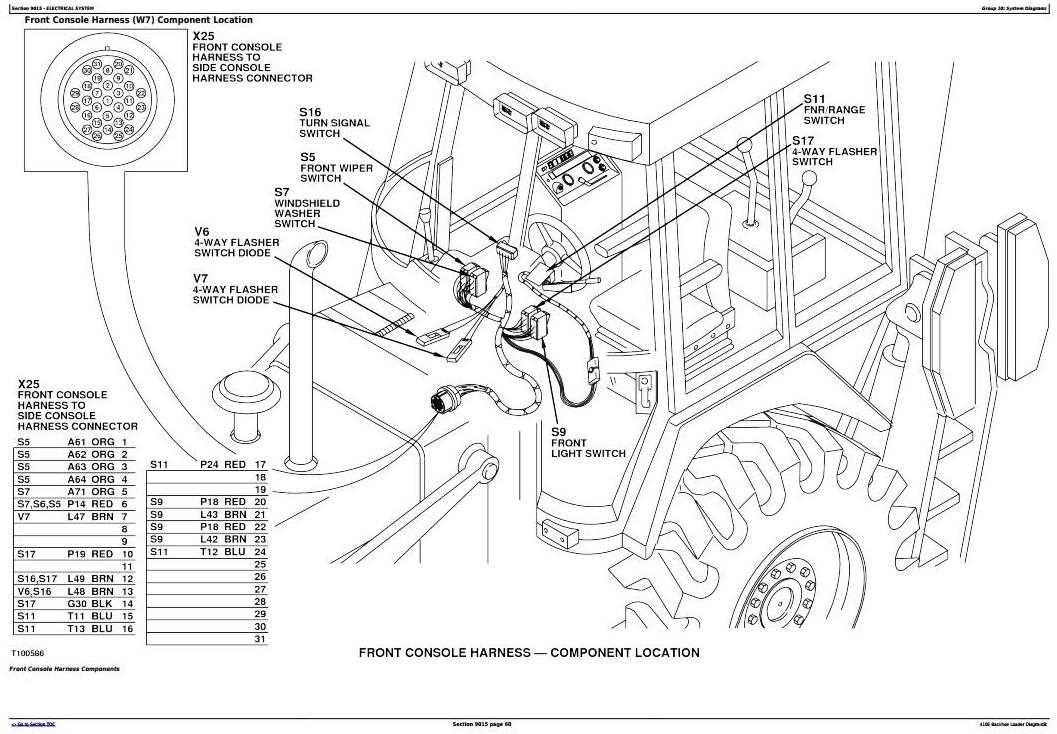

Operational Features: Each unit comes equipped with various functions that facilitate a range of tasks. Understanding how to navigate controls and utilize attachments effectively will enable you to tackle projects with ease. Familiarize yourself with the hydraulic systems and power outputs, as they play a crucial role in achieving optimal results.

Maintenance Requirements: Regular upkeep is vital for any heavy machinery. Be proactive in checking fluid levels, inspecting wear parts, and adhering to recommended service intervals. Establishing a routine maintenance schedule can significantly extend the lifespan of your equipment and reduce downtime.

Safety Protocols: Prioritizing safety is non-negotiable when operating heavy machinery. Always wear appropriate protective gear and remain vigilant of your surroundings. Understanding the specific safety features of your model will help mitigate risks and ensure a secure working environment.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires a commitment to regular upkeep and attention to detail. By following a structured maintenance routine, you can enhance performance and prevent unexpected breakdowns.

1. Regular Inspections: Conduct frequent checks on all components. Look for signs of wear, leaks, and unusual noises. Early detection can save time and resources.

2. Fluid Levels: Maintain proper levels of hydraulic fluid, oil, and coolant. Regularly top off and change these fluids according to the recommended schedule to ensure smooth operation.

3. Clean Filters: Keep air and fuel filters clean and replace them as needed. This helps in maintaining optimal engine performance and efficiency.

4. Lubrication: Apply lubricant to moving parts as specified. This minimizes friction and wear, contributing to a longer service life.

5. Tire Maintenance: Check tire pressure regularly and inspect for any signs of damage or uneven wear. Properly inflated tires improve traction and fuel efficiency.

6. Battery Care: Keep battery terminals clean and ensure connections are secure. Regularly test battery health to prevent starting issues.

7. Seasonal Preparations: Prepare your machine for seasonal changes. Winterizing and summer maintenance can prevent damage and ensure reliability throughout the year.

By adhering to these maintenance practices, you can achieve optimal performance and extend the operational lifespan of your equipment.

Common Troubleshooting Solutions for Owners

When operating heavy machinery, encountering issues is not uncommon. Understanding typical problems and their solutions can help ensure efficient performance and minimize downtime. This guide outlines common challenges and effective troubleshooting methods for operators.

Identifying Common Issues

- Engine Does Not Start

- Hydraulic System Failure

- Unusual Noises During Operation

- Fluid Leaks

- Poor Digging Performance

Troubleshooting Steps

- Engine Does Not Start:

- Check the battery charge and connections.

- Inspect the fuel level and quality.

- Examine the ignition system for faults.

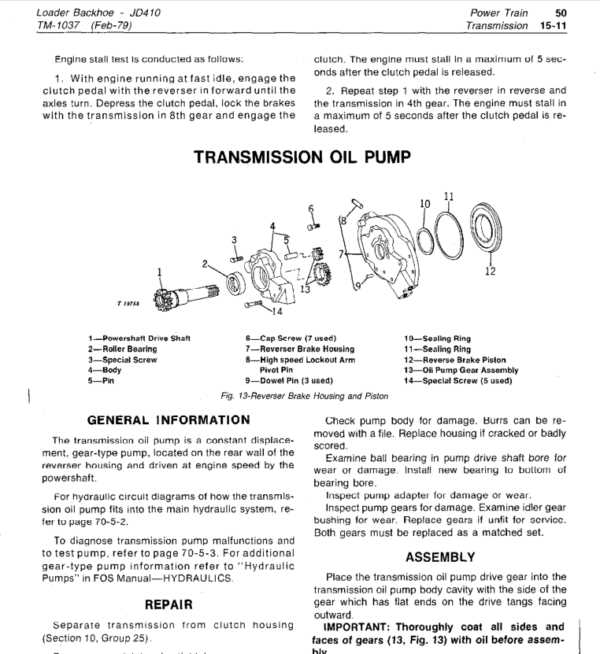

- Hydraulic System Failure:

- Ensure hydraulic fluid levels are adequate.

- Look for signs of leaks in hoses and connections.

- Inspect the hydraulic pump for proper operation.

- Unusual Noises:

- Identify the source of the sound–check for loose components.

- Listen for grinding or whining, which may indicate mechanical failure.

- Fluid Leaks:

- Locate the source of the leak and replace damaged seals or hoses.

- Regularly inspect all connections for wear and tear.

- Poor Digging Performance:

- Check the condition of the bucket and teeth for wear.

- Adjust operating speed and technique based on soil conditions.

By following these troubleshooting steps, operators can effectively address common issues and maintain the performance of their machinery. Regular maintenance and careful observation will further prevent many problems from arising.