For those who own and operate specialized machinery, understanding its functions and maintenance requirements is crucial for optimal performance. Comprehensive resources provide essential insights into operating procedures, safety protocols, and troubleshooting tips, ensuring that users can navigate various scenarios confidently.

Within these informative resources, operators will find detailed descriptions of key components, including how to properly care for and utilize their equipment. By familiarizing themselves with the intricacies of their machinery, individuals can enhance its longevity and efficiency while minimizing potential issues during operation.

Moreover, having access to clear guidance fosters a safer working environment. Knowledge of operational best practices empowers users to make informed decisions, ultimately leading to increased productivity and reduced downtime. Understanding the significance of these resources is the first step toward successful machinery management.

Essential Features of the John Deere 3320

This compact utility tractor is designed for versatility and efficiency, making it an ideal choice for various tasks around the farm or garden. It boasts a range of impressive characteristics that enhance its functionality and user experience.

- Powerful Engine: Equipped with a robust powertrain, this model ensures reliable performance for demanding applications.

- Compact Size: Its smaller dimensions facilitate maneuverability in tight spaces, making it suitable for landscaping and maintenance work.

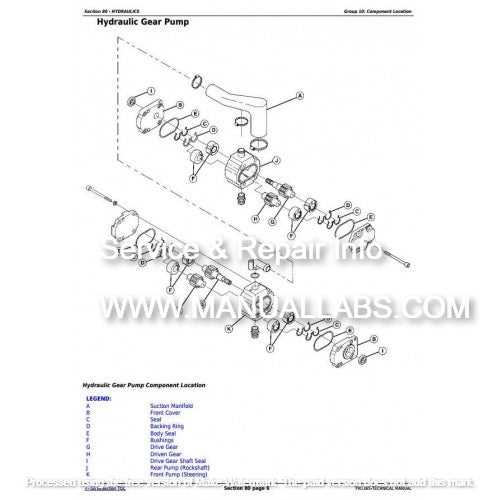

- Hydraulic System: An advanced hydraulic setup allows for seamless attachment changes and optimal implement performance.

- User-Friendly Controls: Ergonomically designed controls enhance ease of operation, reducing fatigue during prolonged use.

- Durable Construction: Built with high-quality materials, this machine is engineered for longevity and resilience in challenging environments.

With these attributes, this tractor stands out as a reliable ally for both professional and recreational users, catering to a wide range of agricultural needs.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring peak efficiency and longevity of your equipment. By adhering to a structured maintenance routine, you can prevent unexpected issues and enhance overall functionality.

Routine Inspections: Conduct frequent assessments of all components to identify any signs of wear or damage. Early detection can save time and resources in the long run.

Fluid Checks: Ensure that all essential fluids, such as oil and coolant, are at appropriate levels. Replenishing these fluids can significantly impact performance and help avoid overheating or engine stress.

Filter Replacements: Regularly replace air and fuel filters to maintain optimal airflow and fuel efficiency. Clean filters promote better combustion and enhance overall power.

Tire Maintenance: Check tire pressure and tread condition frequently. Properly inflated and maintained tires contribute to better traction and stability, improving overall operation.

Battery Care: Inspect the battery for corrosion and ensure secure connections. Keeping the battery in good condition helps maintain reliable starting and electrical performance.

By implementing these maintenance strategies, you can ensure your machinery operates smoothly and efficiently, prolonging its service life and optimizing performance.

Understanding the Operator’s Controls

Familiarizing oneself with the various controls is essential for effective operation. Each element plays a crucial role in ensuring optimal performance and safety during tasks. Grasping the layout and functionality of these components can significantly enhance the user experience.

Primary Controls: The main levers and buttons are designed for essential functions such as movement and speed adjustments. Mastering these controls allows for smoother operation in diverse environments.

Auxiliary Features: Additional functionalities often include attachments and settings that cater to specific tasks. Understanding how to engage and modify these features can optimize the overall efficiency of the equipment.

Safety Mechanisms: Awareness of safety features is vital. Knowing how to utilize emergency stops and alerts ensures that users can maintain a secure working atmosphere.