This section provides essential information designed to enhance your experience with your agricultural equipment. Understanding the various features and functionalities can significantly improve performance and ensure longevity.

In the following paragraphs, you’ll find practical tips and guidelines aimed at optimizing maintenance and operation. Whether you’re a seasoned user or a newcomer, this guide is tailored to support your journey.

By following the outlined recommendations, you can achieve better efficiency and reliability from your machinery. Embrace the opportunity to maximize your productivity and enjoy seamless operations.

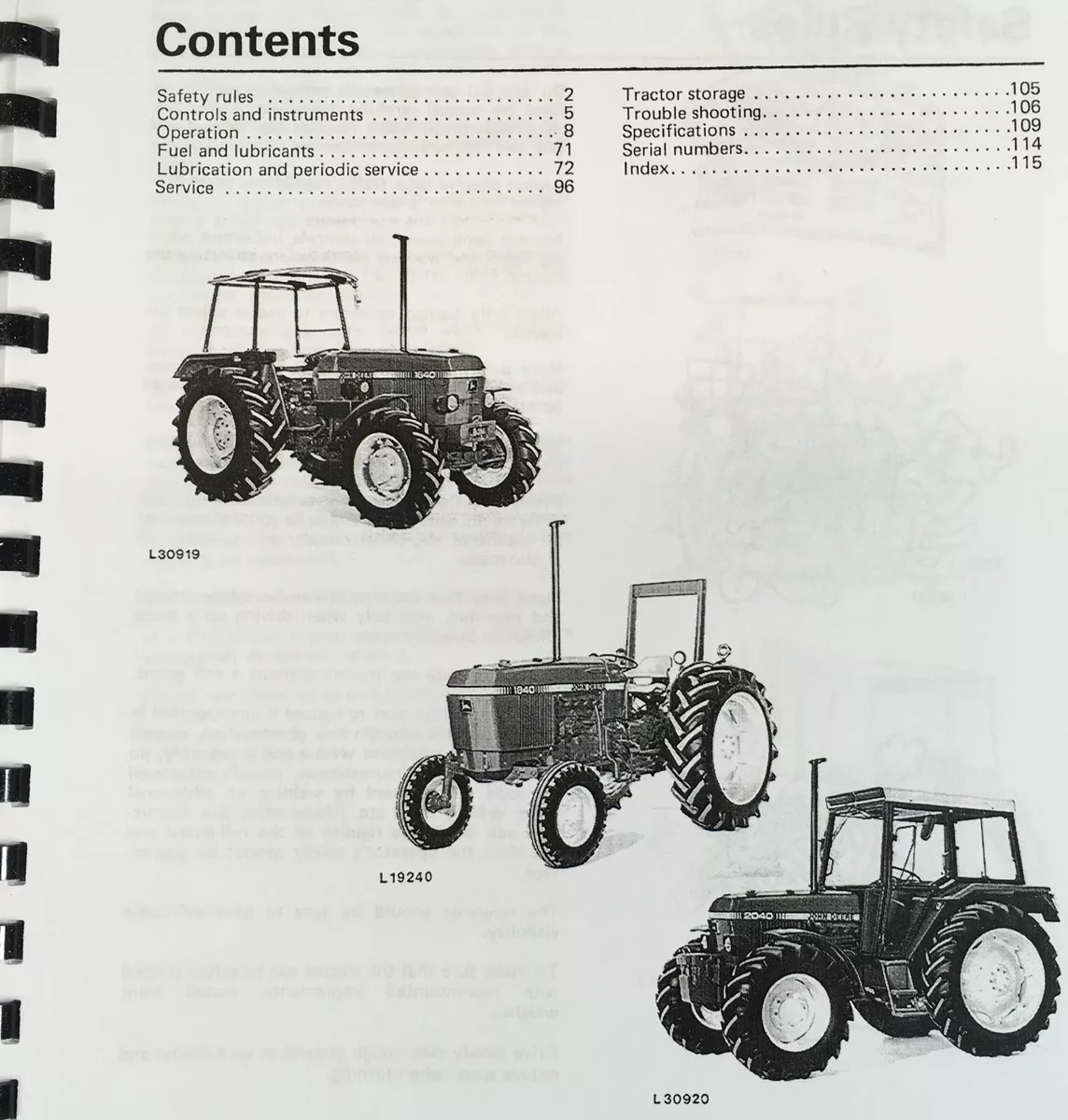

Familiarizing yourself with the capabilities of your agricultural vehicle is essential for optimizing its performance and ensuring efficient operation. This section will explore the various attributes that enhance functionality, making it easier to manage tasks effectively.

Key Features Overview

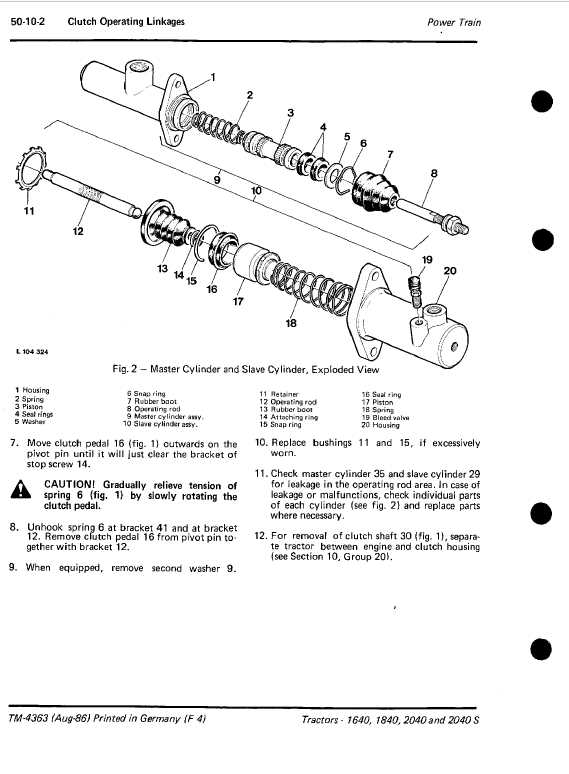

Understanding the main components of your machinery can greatly improve your user experience. Each element is designed to contribute to the overall efficiency and ease of use, whether it involves the engine, transmission, or hydraulic systems.

Operating Specifications

It’s crucial to be aware of the specifications that define the performance of your equipment. This knowledge can assist in making informed decisions regarding maintenance and upgrades.

| Feature | Description |

|---|---|

| Engine Type | Details about the power and efficiency of the engine. |

| Transmission | Overview of the types of gears available for operation. |

| Hydraulic System | Explanation of the hydraulic capabilities and applications. |

| Fuel Efficiency | Insights into consumption rates and optimization tips. |

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. Implementing a structured maintenance routine can prevent issues and enhance overall functionality.

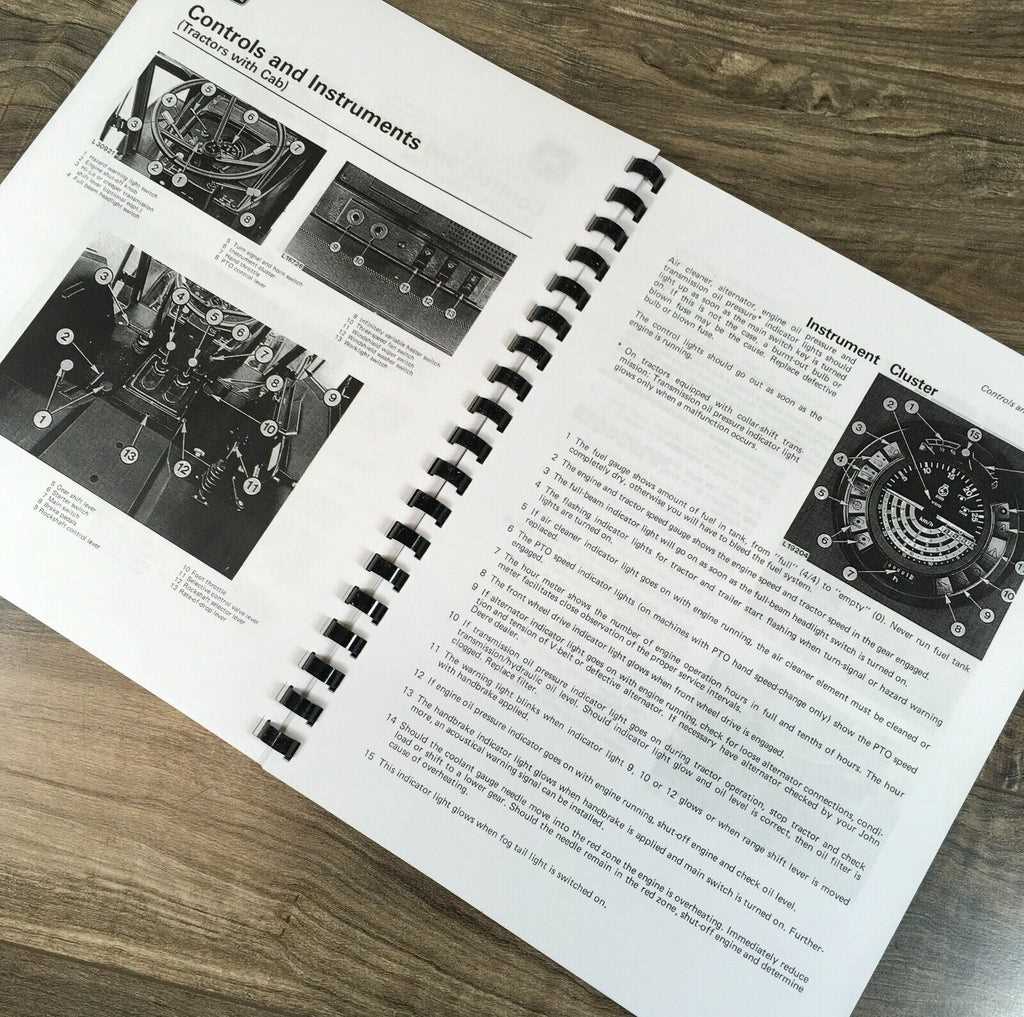

- Regular Inspections: Conduct routine checks to identify any signs of wear and tear. Focus on critical components such as the engine, hydraulic systems, and transmission.

- Fluid Levels: Maintain appropriate levels of oil, coolant, and hydraulic fluid. Regularly check for leaks and replace fluids as needed to ensure smooth operation.

- Air Filters: Inspect and clean air filters regularly to ensure proper airflow and prevent debris from entering the engine.

- Belts and Hoses: Examine belts and hoses for signs of cracking or fraying. Replace any damaged components to avoid breakdowns during operation.

- Cleaning: Keep the machinery clean from dirt and debris. Regular washing can help prevent rust and corrosion, prolonging the lifespan of parts.

By following these guidelines, you can enhance the performance and reliability of your equipment, ensuring it operates at its best for years to come.

Common Issues and Troubleshooting Guide

This section aims to provide insights into frequently encountered challenges and solutions for effective operation. Understanding typical problems can significantly enhance the maintenance experience and ensure optimal functionality.

Engine Performance Problems

One of the most common issues involves engine performance, which may manifest as stalling or reduced power. Check the fuel quality and ensure it meets specifications. Additionally, inspect air filters for blockages that can restrict airflow, leading to inefficiency.

Hydraulic System Failures

Another area to monitor is the hydraulic system. Symptoms like slow or unresponsive movements often indicate issues. Examine hydraulic fluid levels and look for leaks in hoses or connections. Regular maintenance of the hydraulic filter is essential to prevent clogs.