For those who rely on dependable machinery, it’s crucial to understand the intricacies of operating and maintaining the equipment effectively. This document offers a detailed look into key operational procedures, ensuring your machine runs smoothly for years to come. Whether you’re tackling regular upkeep or troubleshooting potential issues, this guide provides the necessary steps to keep everything in top shape.

Delving into various components and their specific functions, this resource aims to offer clear instructions and tips. From proper handling techniques to periodic inspections, everything you need is organized to enhance your overall experience. Following the guidelines will not only prolong the lifespan of your machine but also optimize its efficiency, allowing for better performance across tasks.

Essential Maintenance Tips for Longevity

Regular care is vital to ensure that machinery remains in top condition for years of reliable service. Implementing consistent practices can help avoid unnecessary breakdowns and extend the operational life of the equipment. Below are several key actions that, when performed routinely, will contribute to optimal performance and durability.

Routine Inspections and Cleanliness

Frequent visual assessments are essential to detect any potential issues early on. Pay close attention to components that are prone to wear, such as belts, filters, and moving parts. Cleaning the machine after each use, particularly removing dirt and debris, will prevent buildup that can lead to mechanical problems.

Lubrication and Fluid Checks

Maintaining appropriate fluid levels is crucial for the proper functioning of moving parts. Be sure to check oil, coolant, and other essential fluids regularly. Equally important is the timely lubrication of joints and bearings, which will reduce friction and enhance smooth operation.

| Maintenance Task | Recommended Frequency | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inspect Belts and Filters | Every 25 hours | |||||||||||||||

| Check Fluid Levels | Before each use |

| Maintenance Task | Recommended Frequency | Importance |

|---|---|---|

| Engine oil change | Every 50 hours of operation | Ensures smooth engine function and longevity |

| Air filter inspection | Every 25 hours of operation | Prevents debris from entering the engine |

| Hydraulic fluid check | Monthly | Maintains proper transmission and steering |

| Blade sharpening | As needed, typically after 10-15 hours of mowing | Improves cutting efficiency and prevents grass damage |

Troubleshooting Common Issues and Solutions

Understanding how to address common problems with your equipment is essential for ensuring smooth operation and minimizing downtime. In this section, we’ll explore frequent issues that can arise during use and provide practical solutions to get everything running efficiently again. Whether it’s operational inconsistencies, system malfunctions, or wear-related concerns, having a structured approach to troubleshooting can save both time and effort.

Operational Performance Fluctuations

One of the primary challenges faced involves irregular functionality. This can manifest through uneven responses or intermittent power. A simple check of key connections and essential components often reveals the root cause, typically related to poor connectivity or obstruction. Cleaning or tightening connections may resolve the issue promptly.

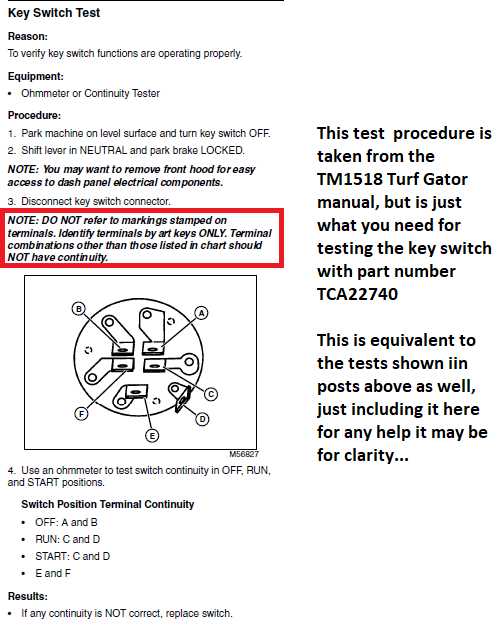

System Malfunctions

Malfunctions in the system may lead to reduced efficiency or total system failure. In such cases, inspecting the main control mechanisms for damage or misalignment is crucial. Regular maintenance, such as lubricating moving parts and replacing worn-out elements, helps prevent breakdowns. If more advanced troubleshooting is required, consulting a service guide may offer further assistance.

Quick Fixes to Keep Your Equipment Running

Regular maintenance is essential to ensure your machinery operates smoothly and efficiently. When minor issues arise, there are simple and effective solutions that can quickly get your equipment back in working order. These quick fixes can help prevent downtime and extend the lifespan of your machine, ensuring it continues to perform at its best.

One of the most common problems is engine-related, often caused by fuel system clogs or worn spark plugs. Cleaning the fuel lines or replacing faulty plugs can immediately resolve starting issues. For equipment that isn’t cutting or moving properly, checking the blades or drive components for wear and damage is essential. Sharpening or replacing worn-out parts can restore performance.

Another quick fix involves the electrical system. Corroded or loose connections can disrupt functionality. Inspecting and cleaning battery terminals or tightening any loose wires can often solve electrical problems. Additionally, lubricating moving parts regularly can reduce friction and prevent overheating, helping the machine run more smoothly.

By addressing these small issues promptly, you can minimize downtime and avoid costly repairs, keeping your equipment in optimal working condition for longer periods of time.

Operating Your Tractor Efficiently

Maximizing the performance of your machine requires an understanding of its core functions and thoughtful operation. Efficient usage helps in conserving fuel, extending the life of the equipment, and ensuring optimal functionality for a variety of tasks. The following guidelines offer practical advice for getting the most out of your tractor.

Maintaining Steady Speeds

One of the key aspects of efficient operation is maintaining a consistent pace, especially when navigating uneven or challenging terrain. Keeping a steady speed ensures that the machinery operates smoothly and prevents unnecessary strain on the components. Always adjust the throttle carefully to match the workload, ensuring an even power distribution across various tasks.

Proper Load Management

Overloading the equipment can lead to reduced performance and potential mechanical issues. Distribute weight evenly and avoid exceeding the machine’s capacity. This practice not only improves fuel efficiency but also enhances overall safety. Regularly check the weight distribution and make necessary adjustments to maintain stability during use.