Maintaining a well-groomed lawn is essential for creating a neat and inviting outdoor space. Using the right tools can make this task easier, ensuring that the yard remains in top condition. In this guide, we’ll explore some important aspects of operating and maintaining a highly reliable grass-cutting machine, offering tips to maximize its performance and lifespan.

From regular upkeep to understanding key functions, proper handling of your equipment can extend its efficiency for many years. We’ll also cover essential practices that ensure the machinery operates safely and effectively during every use. Whether you’re new to this type of machine or looking to refresh your knowledge, the following information will be valuable.

Throughout the guide, we’ll provide insights into how to get the most out of your lawn care device, emphasizing best practices for upkeep and functionality. This will help you keep your outdoor area looking pristine with minimal effort.

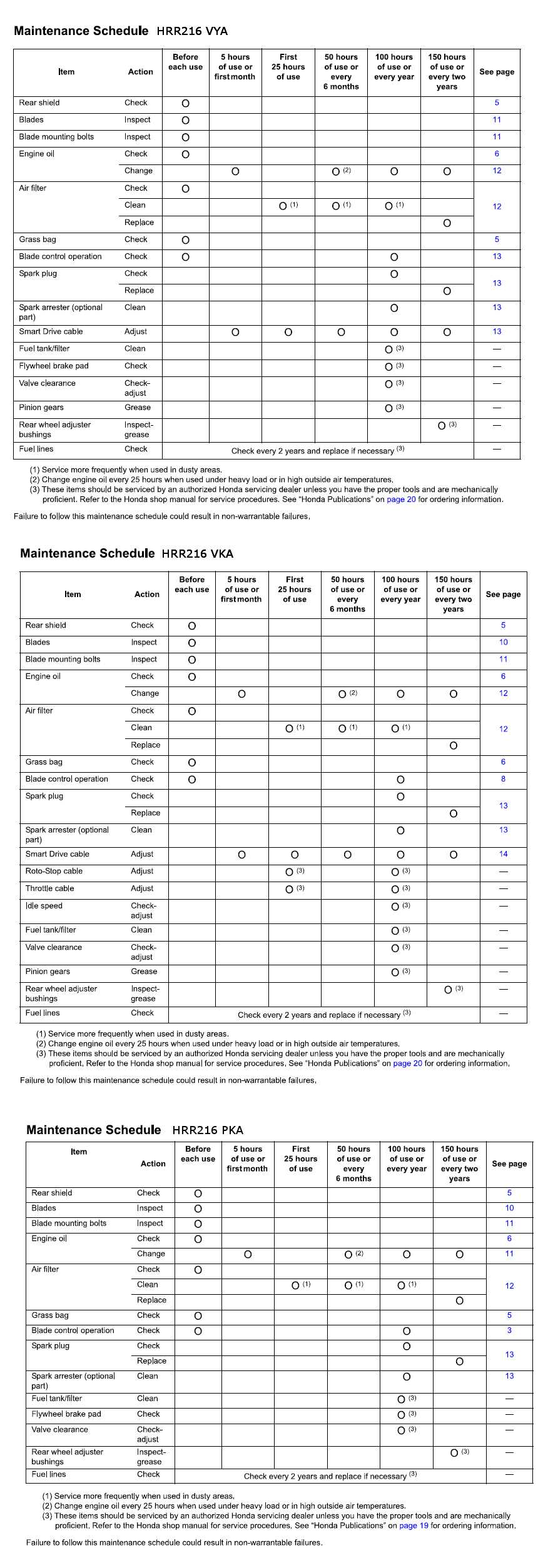

Essential Maintenance Tips

Proper upkeep is crucial to ensure the longevity and efficiency of your equipment. Regular attention to key components can prevent unexpected malfunctions and extend the lifespan of the machine.

- Blade Care: Sharpen the cutting blades regularly to maintain effective grass trimming and avoid uneven cutting patterns.

- Oil Changes: Routinely change the engine oil to keep the internal mechanisms running smoothly and reduce the risk of overheating.

- Air Filter Inspection: Clean or replace the air filter periodically to ensure optimal airflow and prevent engine strain caused by debris buildup.

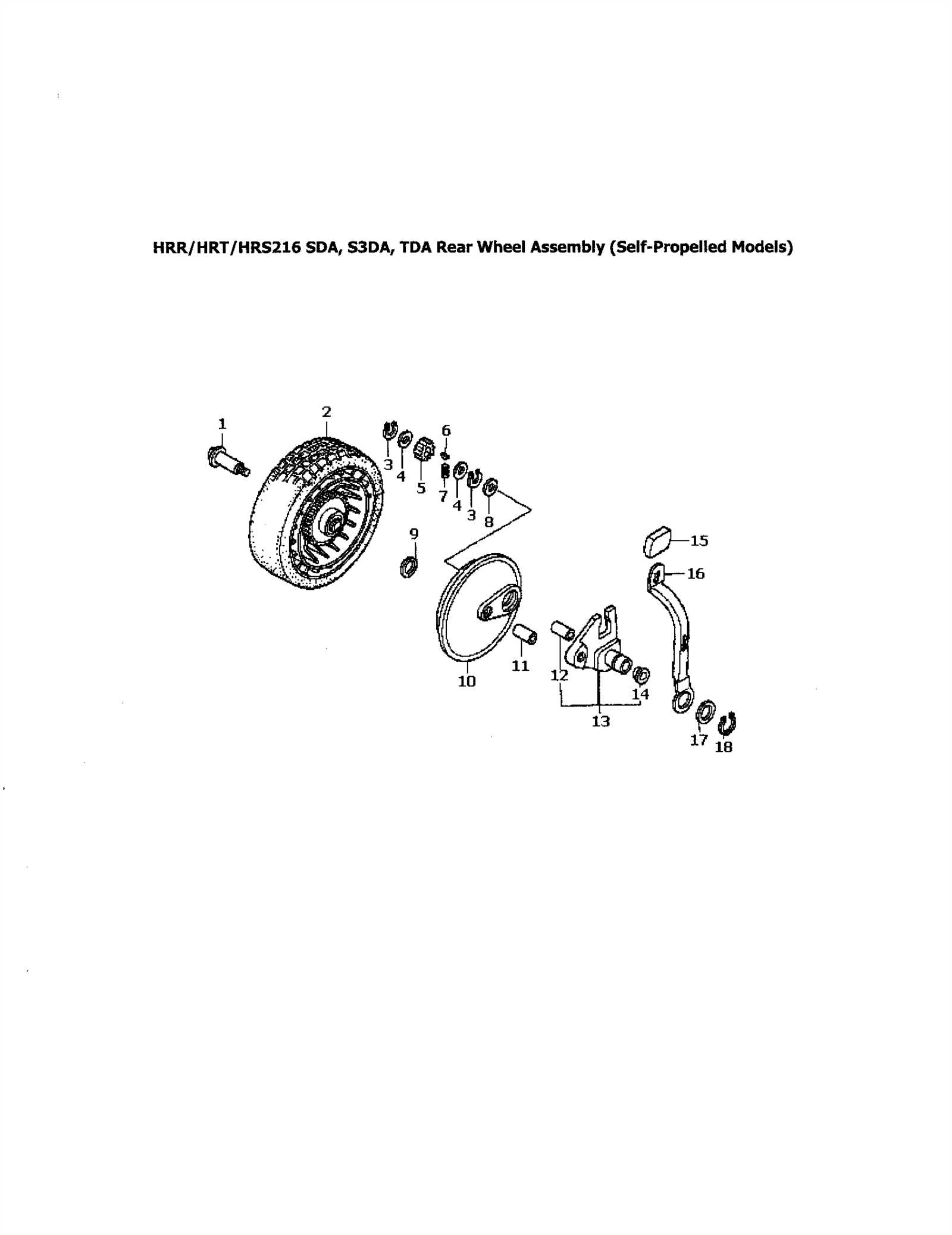

- Wheel Alignment: Check the alignment and condition of the wheels for smooth operation and improved maneuverability on uneven terrain.

- Fuel System Maintenance: Drain any old fuel before storage to avoid engine damage and ensure clean combustion during operation.

By adhering to these simple but effective guidelines, you can enhance the performance of your machine and minimize the need for costly repairs.

Common Troubleshooting Techniques

When it comes to maintaining and repairing your equipment, understanding the root of various issues is essential. With proper techniques, many common problems can be identified and addressed before they lead to more significant damage or costly repairs. This section explores some of the most frequent issues and how to effectively resolve them.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Low fuel or dirty spark plug | Check fuel levels, clean or replace spark plug |

| Poor cutting performance | Dull blade or debris buildup | Sharpen or replace blade, clean under the deck |

| Unusual vibrations | Imbalanced

Understanding Safety and Operation

Proper use and adherence to safety guidelines are crucial for ensuring both the efficiency of the machine and the well-being of its operator. Familiarizing oneself with fundamental principles not only enhances performance but also minimizes risks associated with mishandling. Prioritizing safety involves understanding the mechanics and limitations of the equipment, as well as being aware of any environmental factors that could affect operation. Knowing the controls and their functions is a key step in maintaining smooth and secure operation. In addition, regular inspections are essential for preventing potential hazards. |