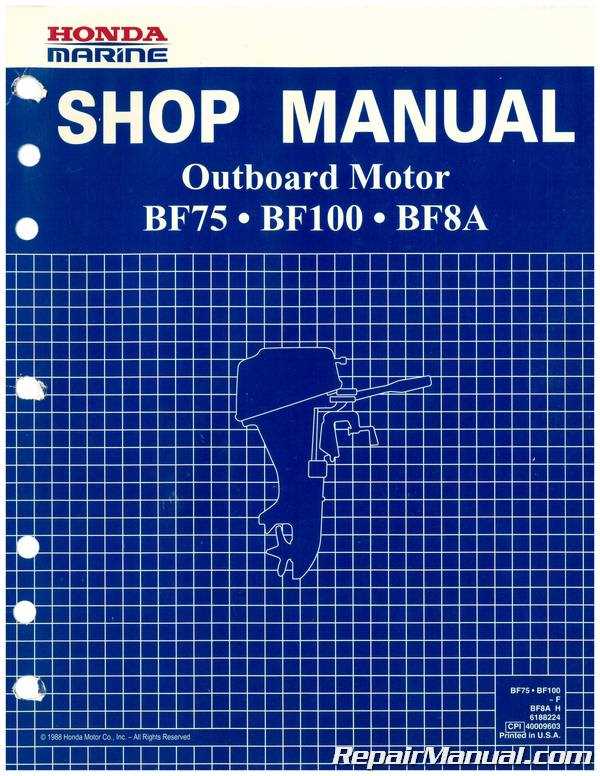

The following section provides an in-depth look at a high-performing marine motor with a power rating of 15 horsepower. This guide aims to offer key insights into maintaining and operating your engine efficiently, ensuring a smooth and reliable experience on the water. Whether you are an experienced boater or just starting out, the information below will help you make the most of your motor’s capabilities.

Proper upkeep and understanding of the various components are essential to ensure longevity and peak performance. By following the advice and recommendations outlined here, you can significantly extend the lifespan of your equipment while optimizing its fuel efficiency and overall output.

This guide also covers key operational techniques, routine maintenance tips, and troubleshooting advice. You will find valuable information about how to handle your engine in various conditions, ensuring that you are prepared for both smooth sailing and unexpected challenges. With these instructions, you can achieve reliable performance and enjoy your time on the water with confidence.

Understanding Your 15 HP Outboard Motor

Getting to know your 15 horsepower marine engine is essential for safe and efficient operation. Whether you’re navigating through calm lakes or cruising along coastal waters, understanding the basic features and functionality of your motor will help ensure a smooth experience on the water. This section provides a concise overview of key aspects to help you better manage and maintain your engine.

Key Components and Functions

The 15 HP engine is equipped with various essential components designed to offer power, control, and reliability. Familiarizing yourself with these parts will enable better performance and troubleshooting. Below is a summary of the primary components and their functions:

| Component | Function |

|---|---|

| Powerhead | The engine’s core, which houses the cylinder and other mechanical parts responsible for generating power. |

| Propeller | Transfers the engine’s power into water movement, enabling forward and reverse motion. |

| Throttle Control | Allows the operator to adjust the engine’s speed and power output as needed during operation. |

| Steering System | Controls the direction of the vessel through a simple handle or wheel mechanism. |

Routine Maintenance and Tips

Regular care is crucial for prolonging the

Maintenance Tips for Long-Lasting Performance

Regular care is essential to ensure that your equipment remains in peak condition for an extended period. By following a few straightforward practices, you can help maximize its efficiency and avoid potential issues that could affect performance over time.

Check and Change the Fluids

Fluids play a vital role in maintaining smooth operation. Always monitor fluid levels and replace them according to the recommended intervals. This prevents any potential damage caused by contamination or degradation.

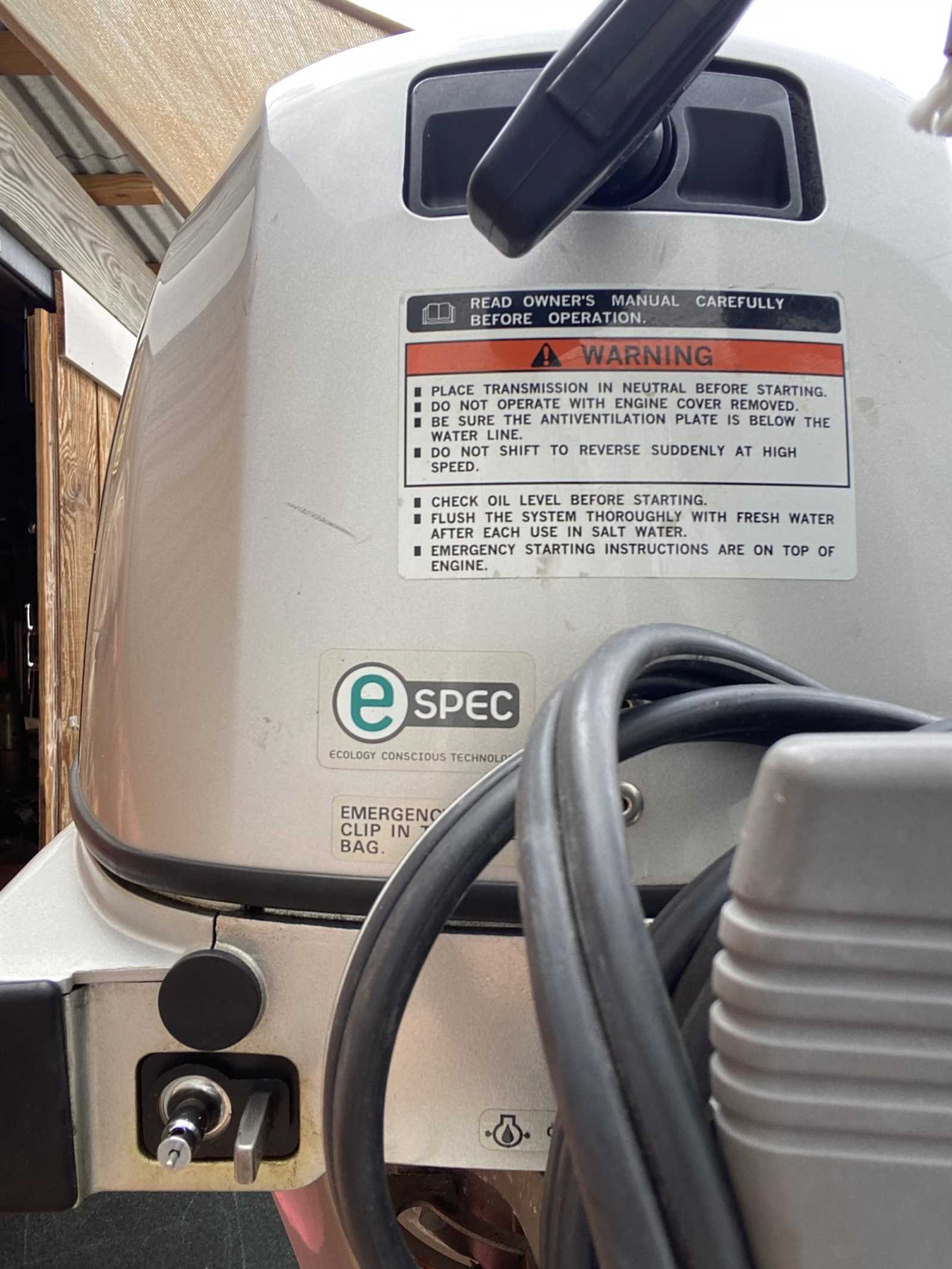

Inspect the Components Regularly

Routinely inspect all mechanical parts for wear and tear. This includes hoses, seals, and fasteners, which can degrade over time. Early detection of wear allows you to replace components before they lead to bigger issues.

Proper storage is also key to maintaining longevity. Ensure your equipment is stored in a clean, dry environment and shielded from harsh elements when not in use. Additionally, covering it can provide extra protection from dust and debris.

By adhering to these maintenance tips, you will help extend the operational life of your equipment, ensuring reliable and efficient performance.

Fuel Efficiency and Operating Best Practices

Maximizing fuel efficiency is essential for both cost savings and minimizing environmental impact. By following a few key strategies, you can ensure smoother and more economical operation, while also extending the life of your equipment. This section outlines practical advice for improving fuel consumption and optimizing performance during use.

| Tip | Description |

|---|---|

| Proper Load Management | Distribute weight evenly to reduce drag, which leads to better fuel economy and enhanced stability. |

| Regular Maintenance | Perform routine inspections and maintenance to keep the system running smoothly, ensuring optimal fuel consumption. |

| Optimal Speed | Operate at moderate speeds where fuel efficiency is highest, avoiding rapid accelerations or prolonged high-speed travel. |

| Correct Propeller Selection | Using a propeller that matches your equipment’s specifications can prevent unnecessary strain and improve efficiency. |

| Engine Warm-Up | Allow the system to warm up before heavy use, reducing strain and improving fuel efficiency. |

Troubleshooting Common Issues with Your Engine

Ensuring the reliable operation of your engine requires regular maintenance and timely attention to potential issues. This section provides guidance on identifying and resolving some of the most frequent problems that can arise during use. Understanding how to address these challenges can help maintain performance and avoid unnecessary downtime.

Engine Won’t Start

If your motor fails to start, several factors could be the cause. It’s important to systematically check each possibility to locate the source of the problem.

- Check the fuel supply – ensure there is sufficient fuel in the tank, and the fuel lines are not clogged or disconnected.

- Inspect the ignition system – confirm that the spark plugs are clean and properly connected.

- Examine the battery – ensure it is fully charged and the terminals are free from corrosion.

Engine Overheating

Overheating is a common issue that can lead to significant engine damage if not addressed promptly. Follow these steps to diagnose and fix overheating problems:

- Ensure that the cooling system is free from blockages, and water is circulating properly through the engine.

- Check the thermostat and replace it if it’s malfunctioning.

- Make sure the water pump is functioning and not obstructed by debris.

Regularly checking and cleaning the cooling system can prevent overheating issues.